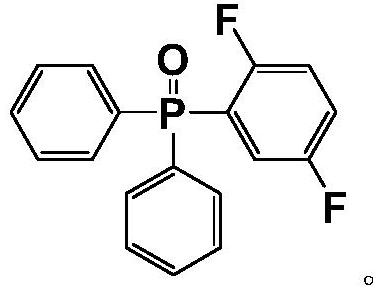

(2,5-difluorophenyl)diphenylphosphine oxide and preparation method thereof

A technology of diphenylphosphine oxide and difluorophenyl, which is applied in the field of diphenylphosphine oxide and its preparation, can solve the problems of few types of polymers and single structure, and achieves easy modification, high safety, excellent resistance to The effect of oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A preparation method of (2,5-difluorophenyl) diphenylphosphine oxide, comprising the following steps:

[0028]

[0029] 1) Under the protection of an inert gas (nitrogen or argon), mix a solution containing 1-bromo-2,5-difluorobenzene (compound A) with a reaction solution containing Mg powder and conduct a grid at 0°C to room temperature reaction for 4h to obtain 2,5-difluorophenylmagnesium bromide (compound B); wherein, the molar ratio of 1-bromo-2,5-difluorobenzene to Mg powder is 1:1, containing 1-bromo- The solution of 2,5-difluorobenzene and the solvent of the reaction solution both include ether or tetrahydrofuran;

[0030] 2) Mix 2,5-difluorophenylmagnesium bromide (compound B) with ether or tetrahydrofuran solution containing diphenylphosphine chloride, and react at 0°C to room temperature for 12h, and use 0.5-1.5mol / L's dilute sulfuric acid, dilute hydrochloric acid or dilute phosphoric acid quench the reaction to obtain (2,5-difluorophenyl)diphenylphosphi...

Embodiment

[0037] A preparation method of (2,5-difluorophenyl) diphenylphosphine oxide, comprising the following steps:

[0038] 1) Under the protection of an inert gas (nitrogen or argon), add 1.2759g Mg powder and 20mL THF to cover the metal in a 250mL round-bottomed three-neck flask equipped with a stirring bar, an addition funnel, a condenser and a gas inlet, to obtain The reaction liquid of Mg powder;

[0039] 2) At room temperature, slowly add 100 mL of a THF solution containing 10.6749 g of 1-bromo-2,5-difluorobenzene to the continuously stirring reaction solution containing Mg powder, and continue to stir for 4 h to obtain 2, 5-difluorophenylmagnesium bromide solution;

[0040] 3) Transfer the 2,5-difluorophenylmagnesium bromide solution to the addition funnel, and add it dropwise to 50mL THF solution containing 11.1953g diphenylphosphine chloride at 0°C, stir for 12h, and then add to 100mL of 1mol / L dilute hydrochloric acid was quenched to obtain (2,5-difluorophenyl)diphenylph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com