Detection method for determining chloroacetic acid residues in cinepazide maleate intermediate through HPLC method

A technology for the detection of cinepazide maleate and its detection method, which is applied in the field of detection of chloroacetic acid residues in cinepazide maleate intermediates by HPLC, and can solve the problem of weak ultraviolet absorption, low boiling point of chloroacetic acid, and hydrocarbon-containing The ratio is small and other problems, to achieve high accuracy of detection results, to overcome the content of chloroacetic acid, the effect of accurate and reliable content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

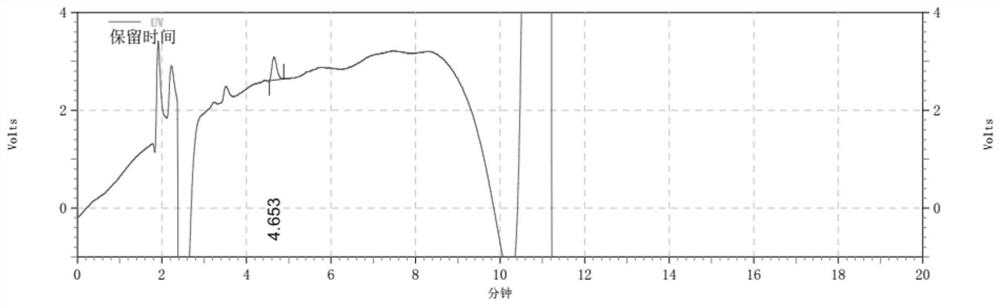

[0043] The detection of chloroacetic acid content in embodiment 1 sample

[0044] According to the consumption of cinepazide maleate intermediate, the limit requirement of chloroacetic acid in this product is 62.5ppm. Use HPLC method to detect residual amount of chloroacetic acid in this product, the signal-to-noise ratio is 33 when the concentration of chloroacetic acid reference substance solution is 5 μ g / ml, it is regarded as 100% limit level solution, must not cross 62.5ppm according to its limit requirement, sample concentration is 80mg / ml. Such a high concentration of sample concentration will greatly damage the life of the instrument and chromatographic column, and the injection concentration should be reduced as much as possible. This product has low solubility in water, and its solubility in acetonitrile is as high as 200mg / ml. Therefore, using the difference in solubility of this product, first use a small amount of good solvent (acetonitrile) to completely dissolv...

Embodiment 2

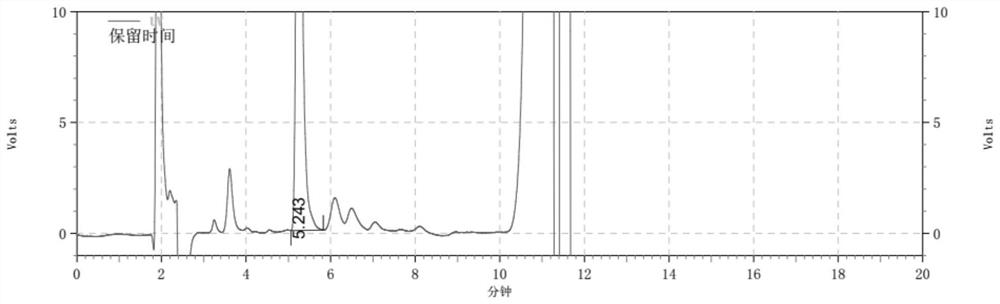

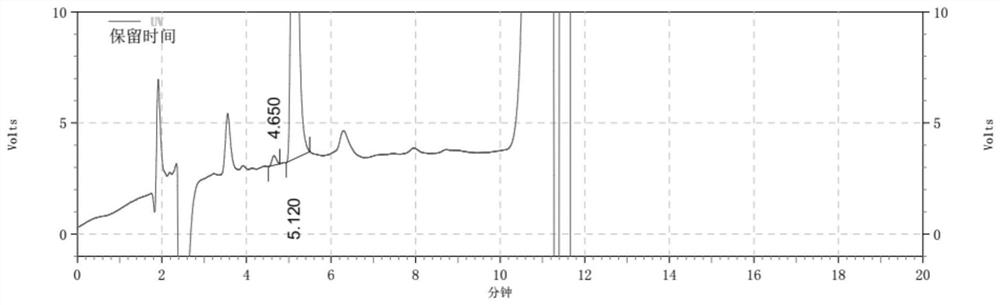

[0065] Embodiment 2 specificity experiment

[0066] Investigate whether the diluent and other components of the sample solution interfere with the chromatographic peak of chloroacetic acid.

[0067] Chloroacetic acid reference substance stock solution (50 μg / ml): Take about 5 mg of chloroacetic acid reference substance, weigh it accurately, put it in a 100ml measuring bottle, add acetonitrile to dissolve and dilute to the mark, shake well, and obtain.

[0068] Chloroacetic acid reference substance solution: Accurately measure 1ml of chloroacetic acid reference substance stock solution, put it in a 10ml measuring bottle, add water to dilute to the mark, and shake well to obtain.

[0069] Sample solution: Accurately weigh 81.7mg of the sample, put it in a 1.5ml EP tube, add 400μl of acetonitrile, vortex to dissolve it completely, add 600μl of water, vortex, centrifuge to get the supernatant, and get ready.

[0070] Sample spike solution: Accurately weigh 82.5mg of the sample, p...

Embodiment 3

[0075] Embodiment 3 system precision experiment

[0076] Take the chloroacetic acid reference solution with a concentration of 5 μg / ml and inject it continuously for 6 times, record the chromatogram, and calculate the RSD of the peak area of chloroacetic acid. The peak area RSD of chloroacetic acid obtained by six consecutive injections is listed in Table 2. It can be seen from Table 2 that the peak area RSD of chloroacetic acid is 1.0%, less than 4%. Therefore, the system precision of this method is good.

[0077] Table 2 System precision results

[0078]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com