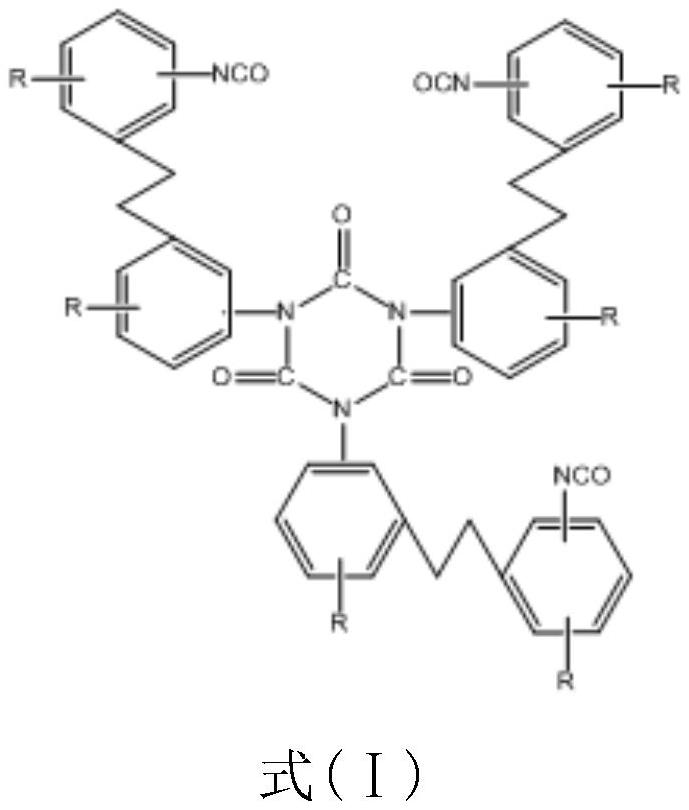

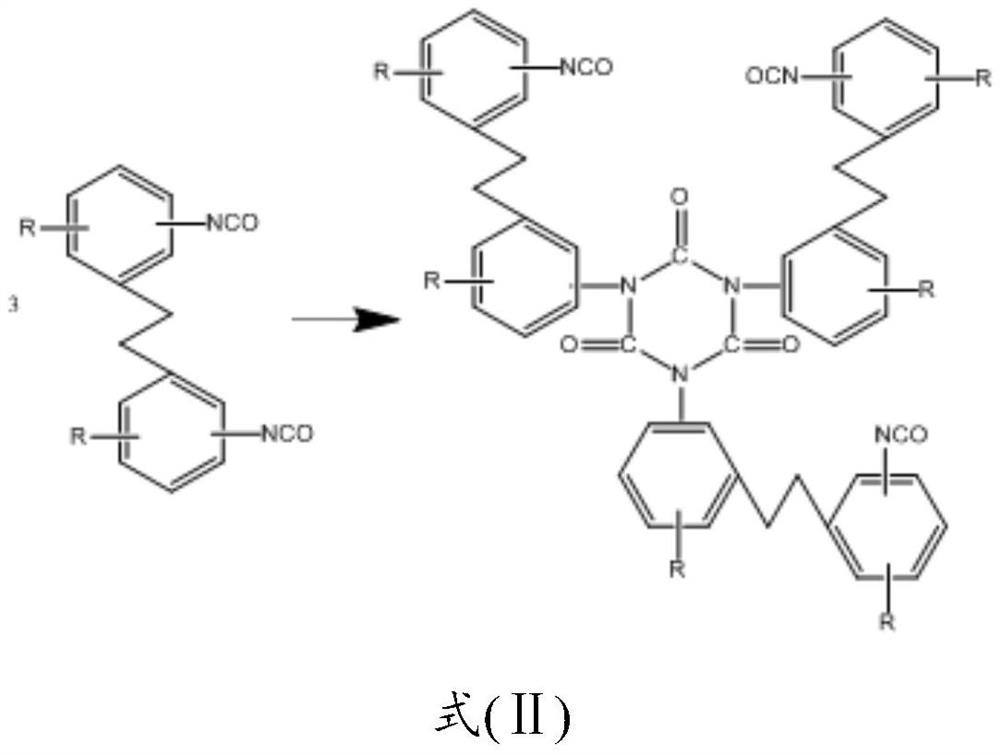

Diphenyl ethane diisocyanate trimer as well as preparation method and application thereof

A technology of diphenylethane diisocyanate and diphenylethane, which is applied in the field of polymer material preparation, can solve the problems of poor heat resistance, poor stability, low softening temperature and decomposition temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

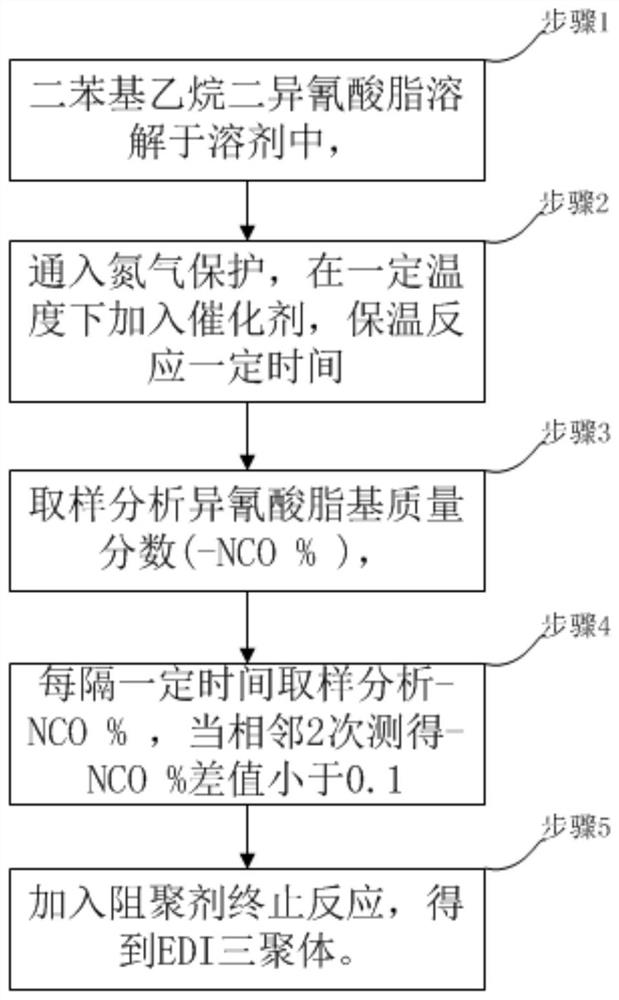

Method used

Image

Examples

Embodiment 1

[0032] Add 250.00L of ethyl acetate into the reaction kettle, blow nitrogen gas to remove water, add 50.00kg of diphenylethane-4,4'-diisocyanate, stir and dissolve at room temperature, heat to 30.0°C and add catalyst N,N-Dimethylbenzylamine 0.05kg, keep warm at 50.0°C for 1h, then take a sample and analyze the mass fraction of isocyanate group (-NCO%) (according to GB / T 13941-92, use di-n-butylamine method-hydrochloric acid titration method ), after that, every 0.5h sampling analysis-NCO%. NCO% reduces along with the carrying out of reaction, determines reaction degree with this, when adjacent 2 times record-NCO% difference value is less than 0.1, adds inhibitor benzoyl chloride 0.10kg to terminate reaction, the colorless or obtained Light yellow transparent liquid, the product detected by FT-IR at 2267cm -1 、1718cm -1 、1419cm-1 3 characteristic absorption peaks appear at , FAB-HRMS (M / e) detection value: 816.7681, molecular formula: C 42 h 36 N 6 o 12 , the product is d...

Embodiment 2

[0037] Add 60.60 L of butyl acetate into the reaction kettle, blow nitrogen gas to remove water, add 50.00 kg of 2,2'-dimethyl-diphenylethane-4,4'-diisocyanate, stir and dissolve at room temperature , add catalyst triethylamine 0.05kg under heating to 30.0°C, keep warm at 60.0°C for 1 hour, then take a sample and analyze the mass fraction of isocyanate group (-NCO%) (according to GB / T 13941-92 with di-n-butylamine method- hydrochloric acid titration), after that, every 0.5h sampling analysis-NCO%. NCO% reduces along with the carrying out of reaction, determines reaction degree with this, when adjacent 2 times record-NCO% difference value is less than 0.1, adds stopper benzoic acid 0.20kg to terminate reaction, obtains colorless or light Yellow transparent liquid, product detected by FT-IR at 2267cm -1 、1718cm -1 、1418cm -1 3 characteristic absorption peaks appear at , FAB-HRMS (M / e) detection value: 844.8212, molecular formula: C 44 h 40 N 6 o 12 , the product is 2,2'-d...

Embodiment 3

[0039] Add 25.50 L of benzyl acetate into the reaction kettle, blow nitrogen gas to remove water, add 50.00 kg of 2,2'-dimethyl-diphenylethane-5,5'-diisocyanate, stir and dissolve at room temperature , add catalyst N, N-diethylbenzylamine 0.05kg under heating to 30.0°C, keep warm at 80.0°C for 1 hour, then sample and analyze isocyanate group mass fraction (-NCO%) (according to GB / T13941-92 with two N-butylamine method-hydrochloric acid titration method), after that, sampling analysis-NCO% was taken every 0.5h. NCO% reduces along with the carrying out of reaction, determines reaction degree with this, when adjacent 2 times record-NCO% difference value is less than 0.1, adds polymerization inhibitor p-toluic acid 0.10kg to terminate reaction, obtains no Color or light yellow transparent liquid, the product is detected by FT-IR at 2264cm -1 、1715cm -1 、1417cm -1 3 characteristic absorption peaks appear at , FAB-HRMS (M / e) detection value: 844.8210, molecular formula: C 44 h ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com