Composite pole sheet and manufacturing method thereof, and lithium ion battery

A production method and pole piece technology, applied in the field of lithium ion secondary batteries, can solve the problems of harsh operating conditions, cumbersome processes, unfavorable large-scale industrial production, etc., and achieve low cost, simple production process and technology, and improved safety performance and cycle. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

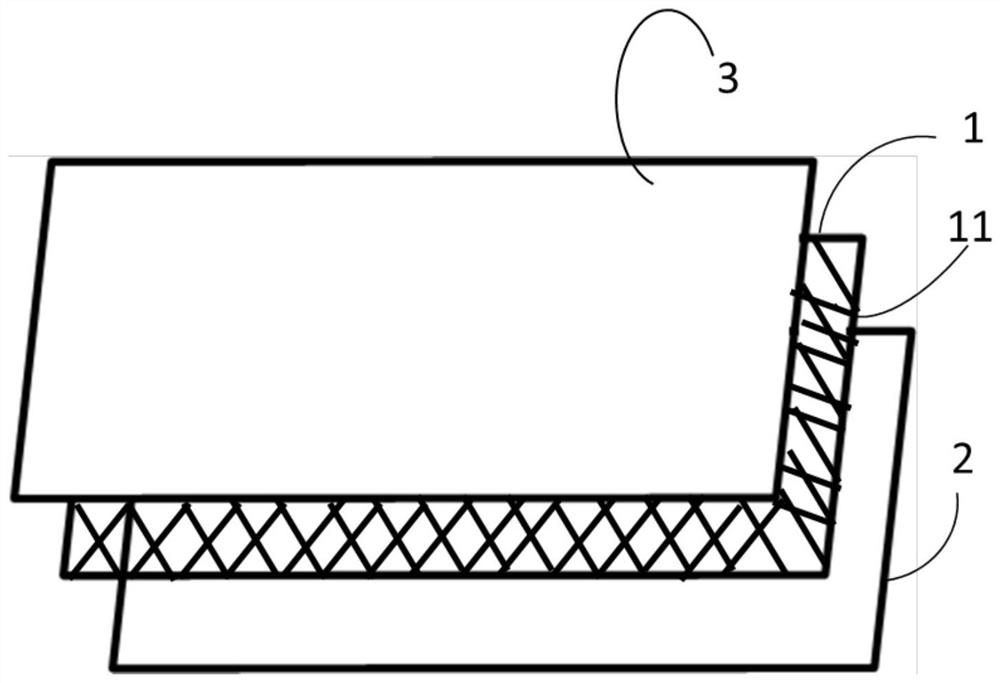

[0038] A preparation method of a lithium metal / carbon nanomaterial composite negative plate, comprising the steps of:

[0039] 1) Dissolve 50mg of SBR in NMP solvent (0.5wt%), and magnetically stir (300rpm / min) at 25°C for 30min to disperse evenly to obtain a reaction solution;

[0040]2) Grind and polish a lithium metal sheet with a size of 8.0cm*6.5cm with a 1000-mesh grinding block, then immerse it in the above reaction solution for 10 seconds, take it out, and place it in a clean watch glass for 10 seconds;

[0041] 3) Submerge the lithium metal sheet treated in step 2) in the graphene powder so that its outer surface is completely covered by black graphene and no lithium metal glossy surface is exposed, and then apply pressure to the lithium metal / graphene with a roller On, until a dense graphene layer is formed on the surface of the lithium metal sheet and no powder falls off, a lithium metal / graphene composite negative electrode sheet is finally obtained.

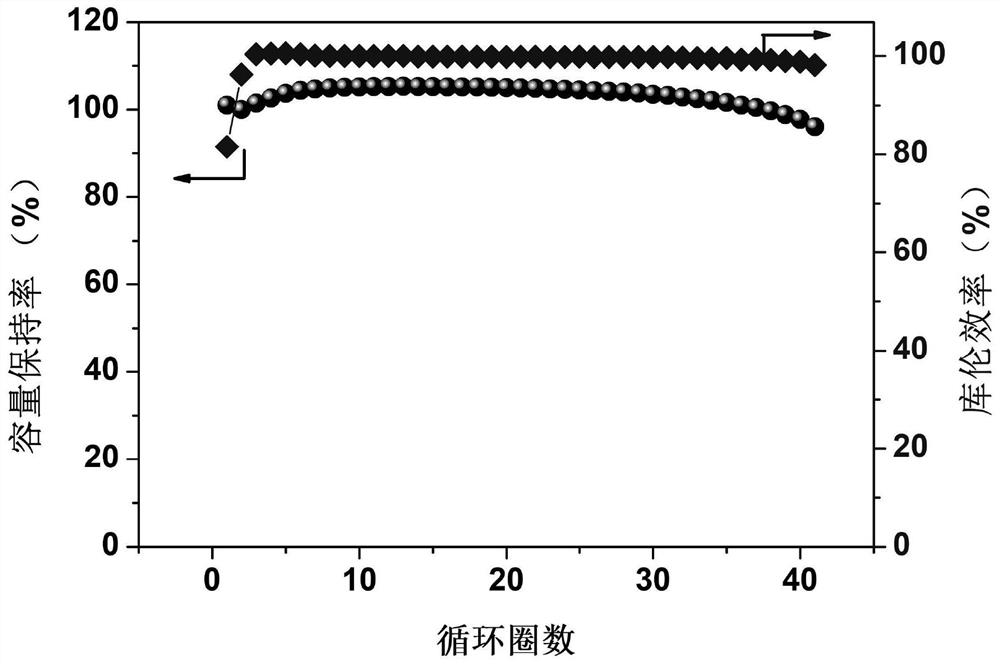

[0042] The ...

Embodiment 2

[0044] A preparation method of a lithium metal / carbon nanomaterial composite negative plate, comprising the steps of:

[0045] 1) Dissolve 50mg of SBR in DMF solvent (1.0wt%), and magnetically stir (300rpm / min) at 25°C for 60min to disperse evenly to obtain a reaction solution;

[0046] 2) Grind and polish a lithium metal sheet with a size of 8.0cm*6.5cm with a 1000-mesh grinding block, then immerse it in the above reaction solution for 20 seconds, take it out, and let it stand for 15 seconds;

[0047] 3) Immerse the lithium metal sheet treated in step 2) in the carbon nanotube powder, so that the outer surface is completely covered by the carbon nanotube and no lithium metal glossy surface is exposed, and then apply pressure to the lithium metal / carbon with a roller. A dense carbon nanotube layer is formed on the nanotube sheet up to the surface of the lithium metal sheet without powder falling off, and finally a lithium metal / carbon nanotube composite negative electrode shee...

Embodiment 3

[0050] A preparation method of a lithium metal / carbon nanomaterial composite negative plate, comprising the steps of:

[0051] 1) Dissolve 100mg of zinc fluoride in THF solvent (1.0wt%), and magnetically stir (300rpm / min) at 25°C for 40min to disperse evenly to obtain a reaction solution;

[0052] 2) Grind and polish a lithium metal sheet with a size of 8.0cm*6.5cm with a 1000-mesh grinding block, then immerse it in the above reaction solution for 30s, take it out, and let it stand for 10s;

[0053] 3) Place a piece of carbon paper (8.0cm*6.5cm) of the same size on the upper and lower surfaces of the lithium metal sheet treated in step 2), and put it into a roller press as a whole, and adjust the pressure to 5MPa to make the lithium metal sheet The surface is closely combined with carbon paper, and finally a lithium metal / carbon paper composite negative electrode sheet is obtained.

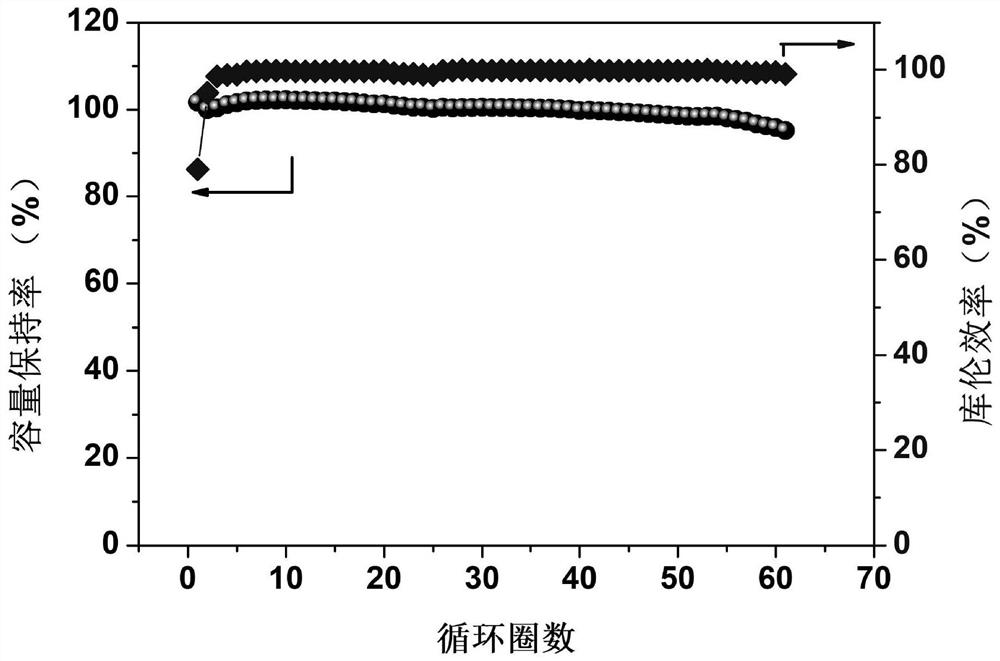

[0054] The obtained lithium metal / carbon paper composite negative electrode sheet, nickel-cob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com