Preparation method and application of beta-phase ferronickel hydroxide/carbon nanotube compound with atomic defects

A technology of hydroxide and carbon nanotubes, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as low density and large specific surface area, and achieve The effects of reduced production costs, uniform size distribution, and simple experimental techniques

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1, Preparation of β-phase nickel-iron hydroxide / carbon nanotube composites with atomic defects

[0023] Weigh 10 mg of carbon dioxide nanotubes in 40 ml of deionized water (N 2 ) in ultrasonic for 30min to disperse, then add 0.0357g (0.0375mol / L) nickel chloride hexahydrate, 0.0299g (0.0375 mol / L) ferrous chloride tetrahydrate, 0.2804g (0.05mol / L) hexamethylene Tetramine and 0.0222g (0.015mol / L) ammonium fluoride were dissolved and transferred to a polytetrafluoroethylene high-temperature autoclave. After reacting at 120°C / 6 h, wait for cooling and wash with deionized water to obtain a black powder . Subsequently, the powder was dispersed in a mixed solution of 50 ml of hydrogen peroxide and water (1:1 by volume) and mechanically stirred for 24 hours, then filtered and washed with deionized water and ethanol, and air-dried at room temperature.

Embodiment 2

[0024] Embodiment 2, preparation of β-phase nickel-iron hydroxide / carbon nanotube composite

[0025] Weigh 10 mg of carbon dioxide nanotubes in 40 ml of deionized water (N 2 ) in ultrasonic for 30min to disperse, then add 0.0357g (0.0375 mol / L) nickel chloride hexahydrate, 0.0299g (0.0375 mol / L) ferrous chloride tetrahydrate, 0.2804g (0.05mol / L) hexamethylene Tetramine and 0.0222g (0.015mol / L) ammonium fluoride were dissolved and transferred to a polytetrafluoroethylene high-temperature autoclave. After reacting at 120°C / 6 h, wait for cooling and wash with deionized water to obtain a black powder .

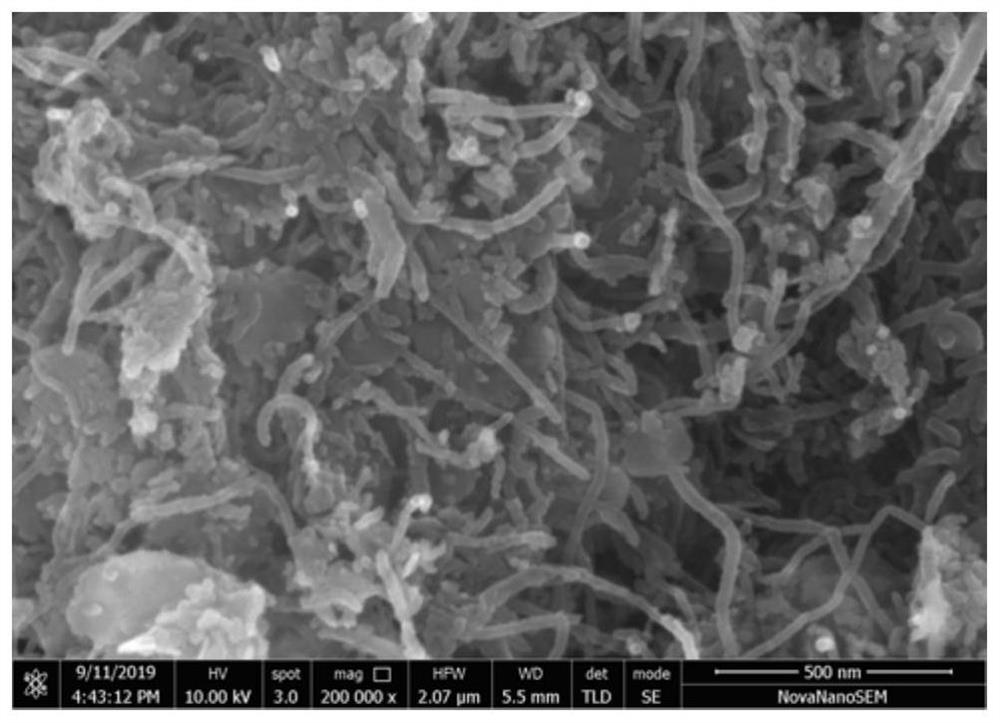

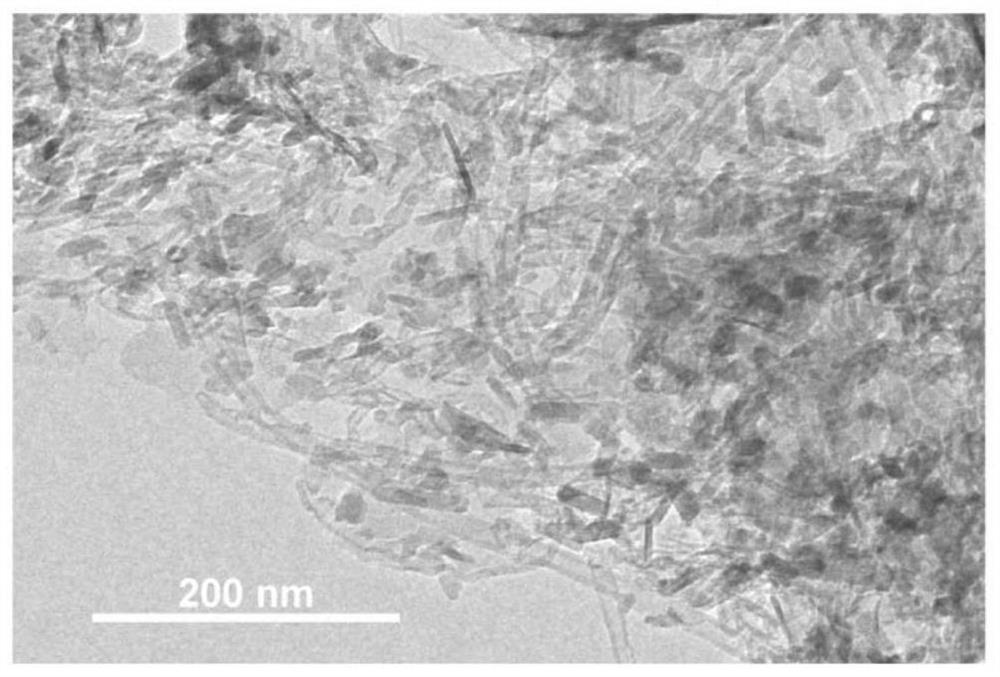

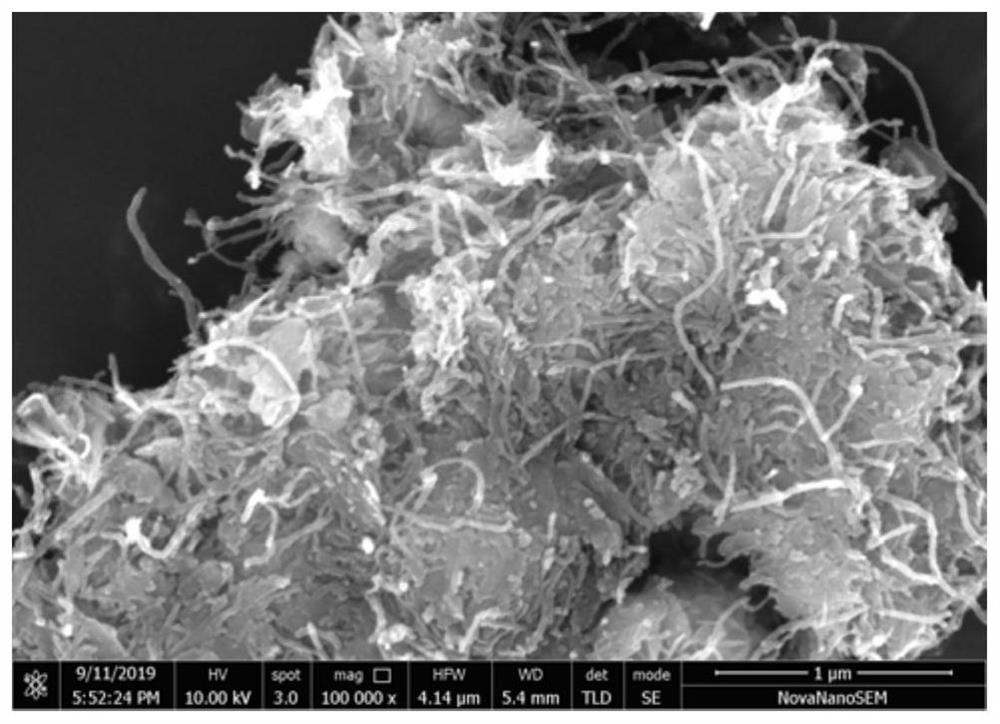

[0026] Synthesized atomically defective β-phase nickel-iron hydroxide / carbon nanotube composites such as Figure 1-2 As shown, indicating the successful growth of nanosheets on carbon nanotubes, the β-phase nickel iron hydroxide / carbon nanotube composites as image 3 shown.

[0027] The oxygen evolution performance of electrolyzed water is as follows: Figure 4 As shown, the ...

Embodiment 3

[0028] Example 3, Preparation of β-phase nickel-iron hydroxide / carbon nanotube composites with atomic defects

[0029] Weigh 5 mg of carbon dioxide nanotubes in 40 ml of deionized water (N 2) in ultrasonic for 30min to disperse, then add nickel chloride hexahydrate 0.05625mol / L, ferrous chloride tetrahydrate 0.01875mol / L, hexamethylenetetramine 0.03mol / L and ammonium fluoride 0.035mol / L after dissolving It was transferred to a polytetrafluoroethylene high-temperature autoclave, reacted at 120°C for 24 h, and was cooled and washed with deionized water to obtain a black powder. Then the powder was dispersed in a mixed solution of 50 mL of hydrogen peroxide and water (volume ratio 1:1) and mechanically stirred for 36 hours, then deionized water and ethanol were used to filter and wash the β-phase nickel iron with atomic defects air-dried at room temperature Hydroxide / Carbon Nanotube Composite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com