Multi-level metal phosphide as well as preparation method and application thereof

A metal phosphide, multi-level technology, applied in the field of electrocatalytic materials, can solve the problem of expensive precious metals, achieve high repeatability, improve catalytic performance, and reduce overpotential effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

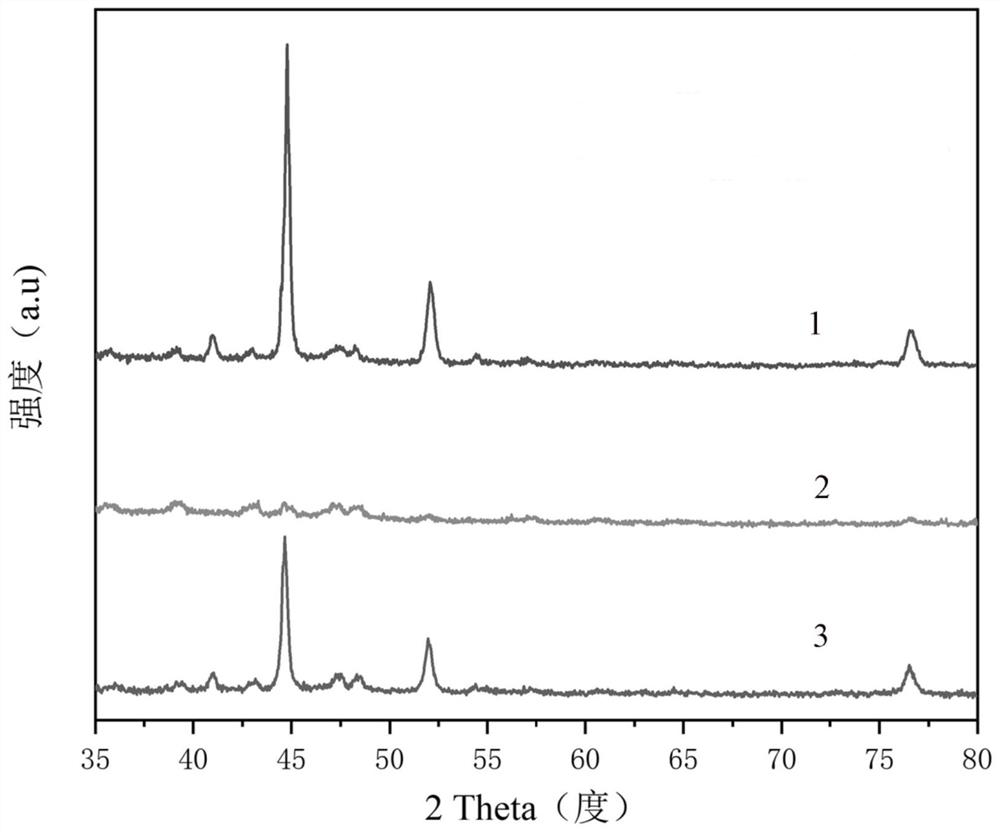

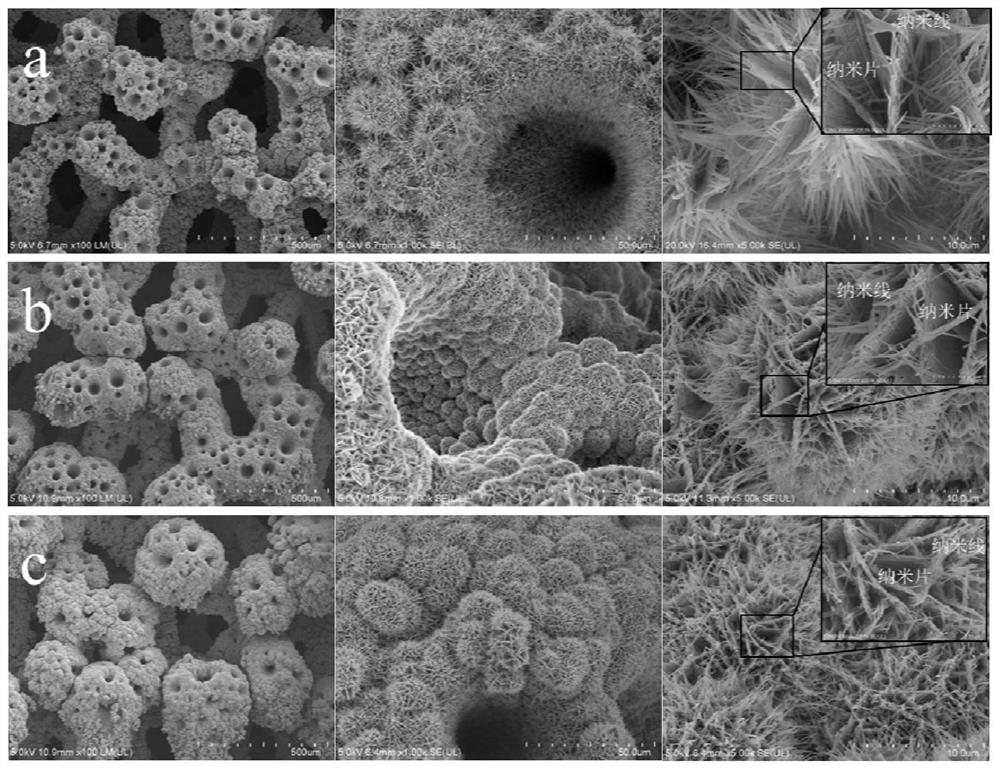

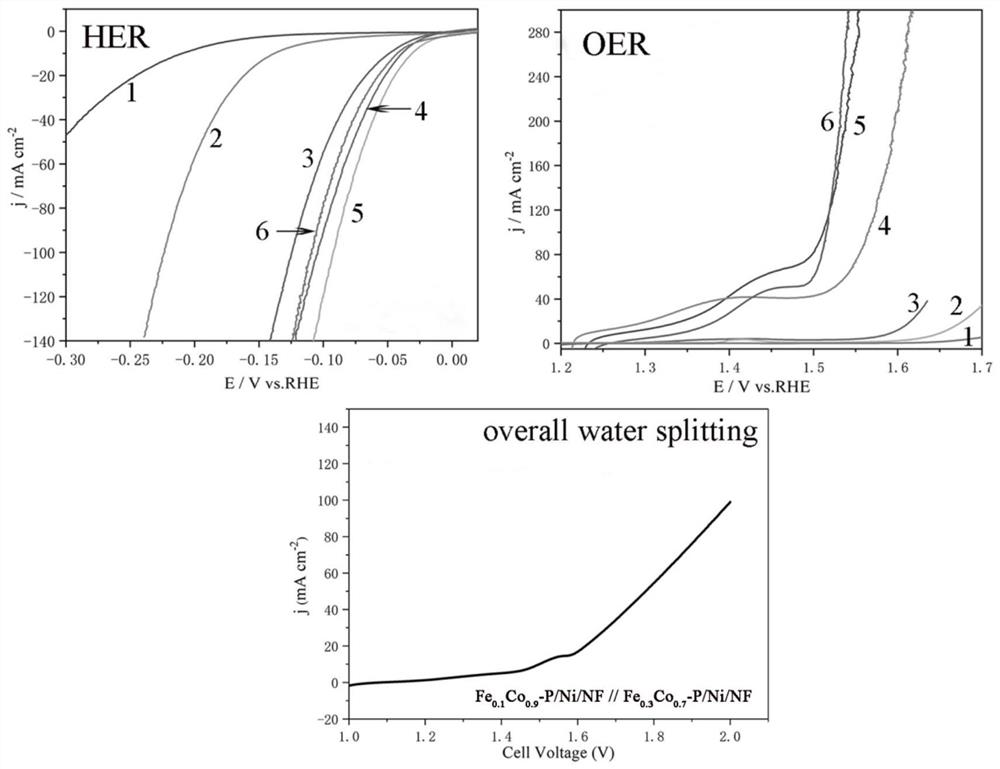

[0056] This example provides a multi-level metal phosphide with a special "woven bag" structure (Fe:Co=0:10, molar ratio, the same below), and its preparation process is as follows:

[0057] Nickel foam (with an average pore size of 250 microns) was ultrasonically cleaned with 1 mol / L hydrochloric acid, deionized water, and ethanol for 10 minutes respectively. Then prepare 30mL of a mixed solution of 0.1mol / L nickel chloride and 2mol / L ammonium chloride as the electrolyte, the nickel sheet as the counter electrode and reference electrode, the cleaned nickel foam as the working electrode, and submerge the nickel foam into the electrolyte 1cm 2 , in two-electrode mode with -1A cm -2 The constant current program was used for 500 seconds, and the resulting nickel foam was washed with deionized water and dried in a vacuum oven. Then soak the above 4 pieces of dried nickel foam in 25mL of an aqueous solution prepared by dissolving 1mmol of cobalt nitrate hexahydrate, 2.5mmol of am...

Embodiment 2

[0059] This example provides a multi-level iron-cobalt bimetallic phosphide (Fe:Co=1:9) with a special "woven bag" structure, and its preparation process is as follows:

[0060] Nickel foam (with an average pore size of 250 microns) was ultrasonically cleaned with 1 mol / L hydrochloric acid, deionized water, and ethanol for 10 minutes respectively. Then prepare 30mL of a mixed solution of 0.1mol / L nickel chloride and 2mol / L ammonium chloride as the electrolyte, the nickel sheet as the counter electrode and reference electrode, the cleaned nickel foam as the working electrode, and submerge the nickel foam into the electrolyte 1cm 2 , in two-electrode mode with -1A cm -2 The constant current program was used for 500 seconds, and the resulting nickel foam was washed with deionized water and dried in a vacuum oven. Then soak the above 4 pieces of dried nickel foam in 25mL of an aqueous solution prepared by dissolving 0.1mmol ferric nitrate nonahydrate, 0.9mmol cobalt nitrate hexa...

Embodiment 3

[0062] This example provides a multi-level iron-cobalt bimetallic phosphide (Fe:Co=3:7) with a special "woven bag" structure, and its preparation process is as follows:

[0063] Nickel foam (with an average pore size of 250 microns) was ultrasonically cleaned with 1 mol / L hydrochloric acid, deionized water, and ethanol for 10 minutes respectively. Then prepare 30mL of a mixed solution of 0.1mol / L nickel chloride and 2mol / L ammonium chloride as the electrolyte, the nickel sheet as the counter electrode and reference electrode, the cleaned nickel foam as the working electrode, and submerge the nickel foam into the electrolyte 1cm 2 , in two-electrode mode with -1A cm -2 The constant current program was used for 500 seconds, and the resulting nickel foam was washed with deionized water and dried in a vacuum oven. Then soak the above 4 pieces of dried nickel foam in 25mL of an aqueous solution prepared by dissolving 0.3mmol ferric nitrate nonahydrate, 0.7mmol cobalt nitrate hexa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com