Microporous activated carbon fiber and preparation method thereof

An activated carbon fiber and microporous technology, which is applied in the field of microporous activated carbon fiber and its preparation, can solve the problems of reducing fiber strength, low carbonization temperature, and reducing yield, and achieves enhanced adsorption force, large specific surface area, and high yield. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

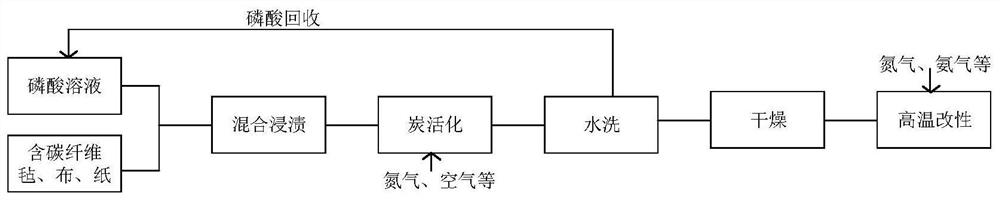

Method used

Image

Examples

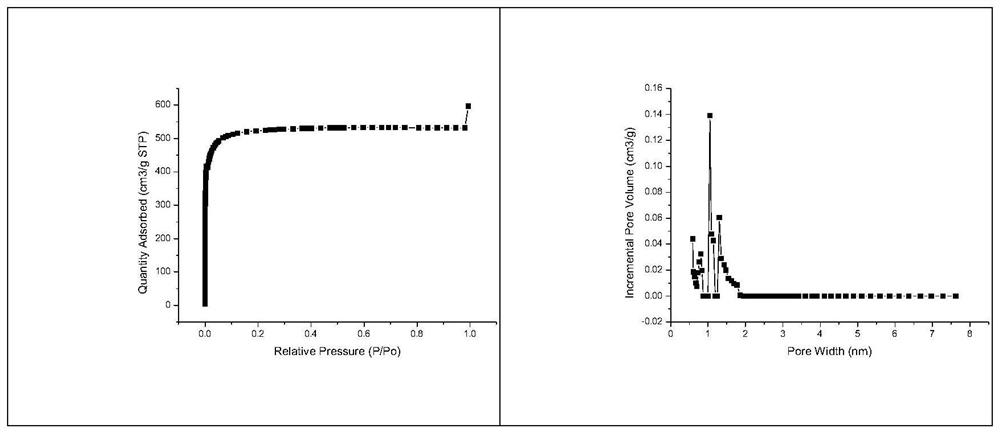

Embodiment 1

[0039] A microporous activated carbon fiber, the ash content of the activated carbon fiber is 1.25wt%, the ignition point is 413°C, and the specific surface area is 2089m 2 / g, no sticking problem, the wicking height is 15cm, the O element content accounts for 13.41%, the C element content accounts for 69.86%, and the H element content accounts for 1.95%; the pore size distribution is as follows figure 2 As shown, the proportion of pores below 0.8nm is about 45%, and the proportion of pores of 0.8-2nm is about 55%.

[0040]The preparation method is: mix viscose fiber mat with 12% phosphoric acid solution according to the ratio of fiber to phosphoric acid mass ratio of 1:0.6, impregnate at 40°C for 30min, dry with hot air at 50°C for 5 hours, and then carbonize under nitrogen atmosphere Treatment, carbonization selects the gradient heating process, that is, the temperature of the first gradient is 90°C and the time is 20min, the temperature of the second gradient is 220°C and ...

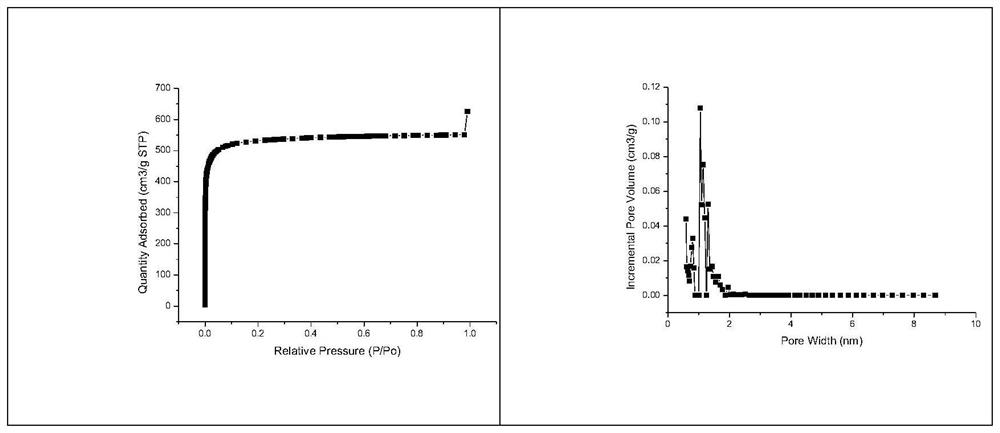

Embodiment 2

[0043] A microporous activated carbon fiber, the ash content of the activated carbon fiber is 1.93wt%, the ignition point is 435°C, and the specific surface area is 1966m 2 / g, no sticking and filament problem, the wicking height is 13cm, the O element content accounts for 8.05%, the C element content accounts for 89.03%, and the H element content accounts for 1.61%; the pore size distribution is as follows image 3 As shown, the proportion of pores below 0.8nm is about 48%, and the proportion of pores of 0.8-2nm is about 52%.

[0044] The preparation method is as follows: solvent method cellulose fiber mat and 7% phosphoric acid solution are mixed according to the ratio of fiber to phosphoric acid mass ratio of 1:0.8, soaked at 50°C for 30min, dried at 30°C for 7 hours, and then carried out in air atmosphere Carbonization treatment, carbonization selects a gradient heating process, that is, the temperature of the first gradient is 100°C and the time is 30min, the temperature ...

Embodiment 3

[0047] A microporous activated carbon fiber, the ash content of the activated carbon fiber is 1.14wt%, the ignition point is 445°C, and the specific surface area is 1655m 2 / g, no sticking and filament problem, the wicking height is 9cm, the O element content accounts for 5.07%, the C element content accounts for 85.55%, and the H element content accounts for 1.13%; the pore size distribution is as follows Figure 4 As shown, the proportion of pores below 0.8nm is about 50%, and the proportion of pores of 0.8-2nm is about 50%.

[0048] The preparation method is: mix cupro ammonia fiber cloth with 15% phosphoric acid solution according to the mass ratio of fiber and phosphoric acid of 1:0.2, soak at 60°C for 60min, dry at 60°C for 3 hours, and then carbonize under nitrogen atmosphere , the carbonization selects the gradient heating process, that is, the temperature of the first gradient is 120°C and the time is 40min, the temperature of the second gradient is 180°C and the time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| ignition point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com