Efficient flotation collecting agent for zinc sulfide and application of agent

A collector, zinc sulfide technology, applied in flotation, chemical instruments and methods, solid separation and other directions, can solve the problems of low zinc recovery rate, slow zinc floating speed, large amount of copper sulfate, etc., to achieve efficient recovery of zinc, The effect of high cost of chemicals and high cost of wastewater treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A Inner Mongolia sulfur as lead-zinc ore, lead ore 3.01%, 2.43% zinc, 21.35% sulfur. The lead-zinc sulphide ore sulfur ore belongs. Complex ore mineral composition, each as a mineral fine disseminated ore is the major metallic minerals pyrite, galena and sphalerite iron, limonite small or trace amounts of lead sulfate or the like cerussite . Zinc sulfide minerals in the mine (including Fe> 8%) Marmatite mainly poor floatability, flotation recovery difficult. High sulfur content ore, will interfere with the flotation of lead and zinc.

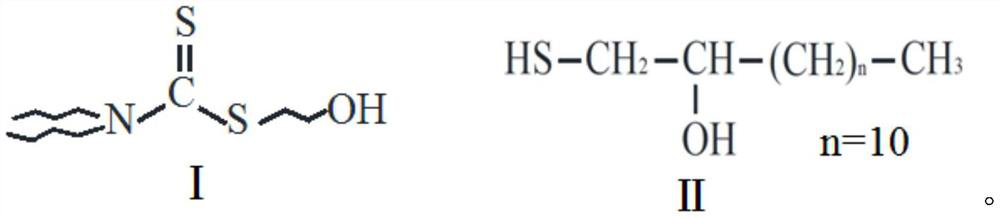

[0032] In this embodiment from 2-hydroxyethyl HQ-Zn dibutyl dithiocarbamate (structural formula shown Ⅰ), 2-hydroxy-1-thiol mercapto group (e.g., the structure shown in Formula Ⅱ) and octanol mass percent accounted for 95.5%, 2%, 2.5%, uniformly mixed by adding liquid.

[0033]

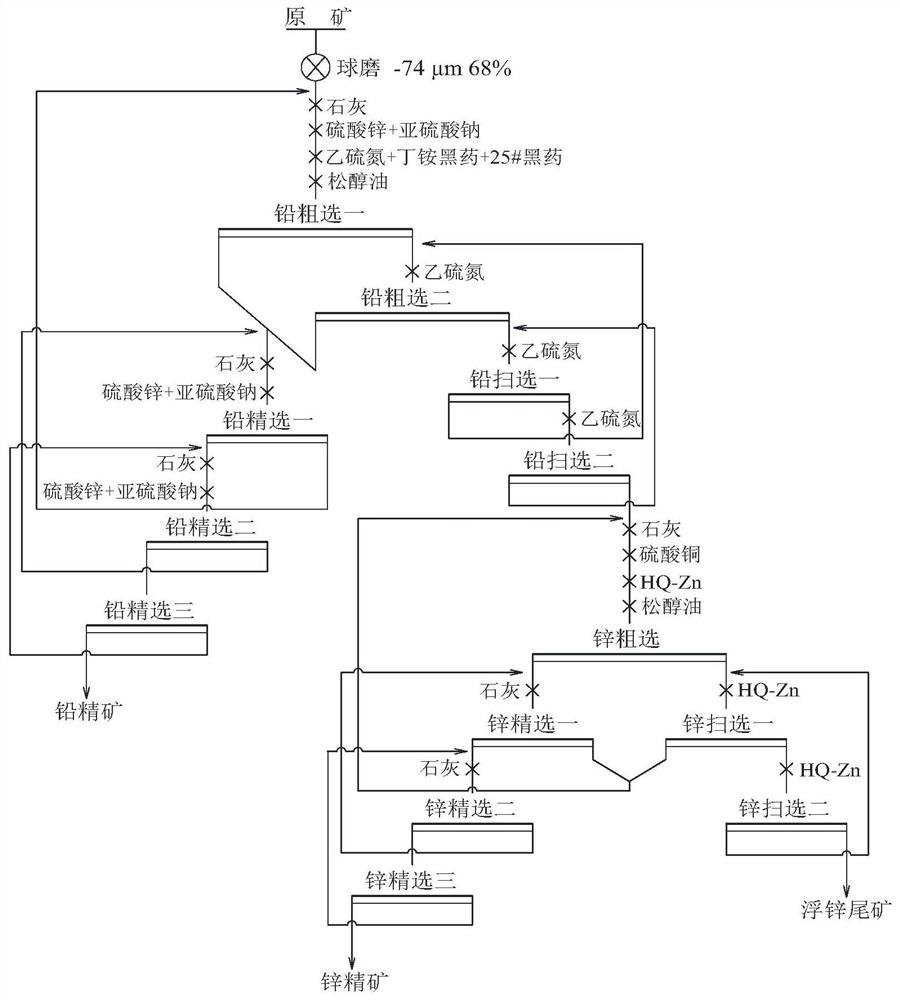

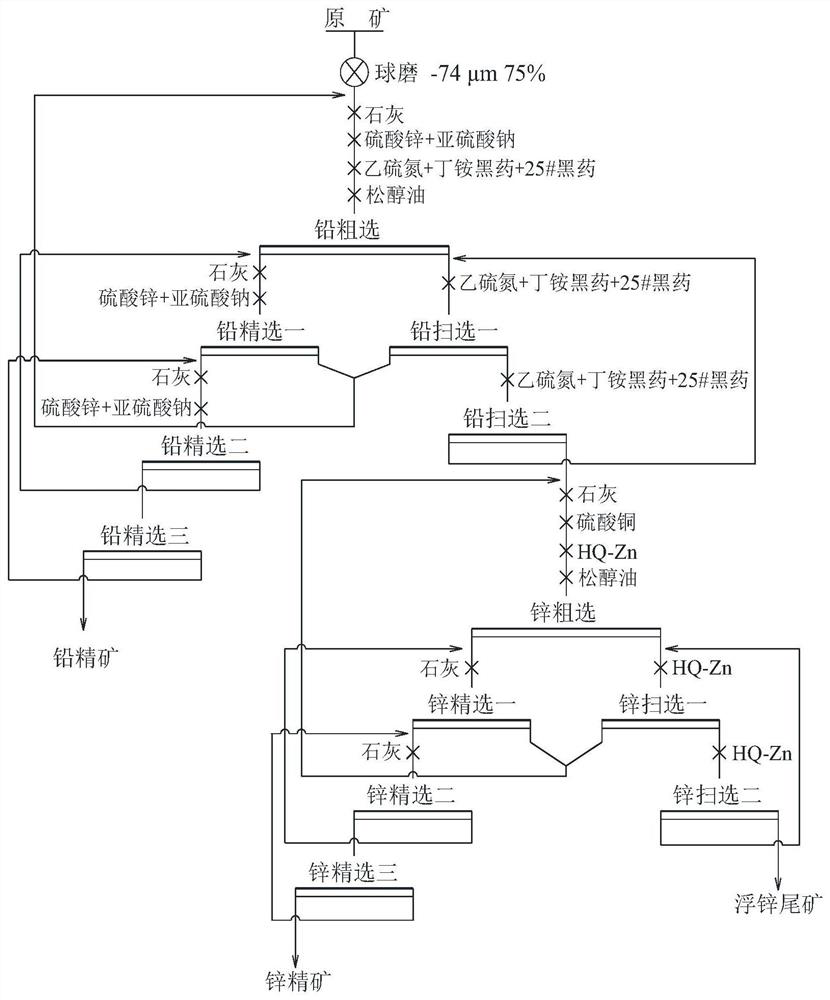

[0034](1) The original mine uses the process of lead and zinc minerals with priority floating lead and zerce zinc; the original mine mills to the milling fineness ...

Embodiment 2

[0050] The process flow is basically the same as in Example 1, and the zinc coarse selection uses HQ-Zn, but the dosage amount is adjusted. The flotation results are shown in Table 1.

[0051] Zinc coarse: lime 500g / t, copper sulfate 200g / t, HQ-Zn50 g / t, pine alcohol oil 9g / t; zinc scans one: HQ-Zn30g / t; zinc scans 2: HQ-Zn 15g / T; zinc selection 1: lime 200g / t; zinc selection 2: lime 100g / t; results shown in 5 # in Table 1.

Embodiment 3

[0053] The process flow is basically the same as in Example 1, and the zinc coarse selection uses HQ-Zn, but the dosage amount is adjusted. The flotation results are shown in Table 1.

[0054] Zinc coarse: lime 500g / t, copper sulfate 200g / t, HQ-Zn 30g / t, pine alcohol oil 9g / t; zinc scans one: HQ-Zn10 g / t; zinc scans 2: HQ-Zn 5g / t; zinc selection 1: lime 200g / t; zinc selection 2: lime 100g / t; results shown in Table 1.

[0055] Table 1 Test 1 # ~ Test 7 # full process closed circuit comparison test results / %

[0056]

[0057]

[0058] As can be seen from Table 1, HQ-Zn (Example 1 (7 #)) is relative to a single capture agent Hedd (ratio 1 (2 #)), DET (ratio 3) (3 #)), the zinc-zinc grace in the zinc concentrate obtained by HQ-Zn is 51.41%, and the recovery rate of zinc operation is also 93.90%. When the three pharmaceutical groups are combined with zinc capture, a synergistic effect is produced. Get better zinc fluttering results. Contrast HQ-Zn (Example 1 (7 #))...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com