Intercropping biological fermented feed for palaemon carinicauda and swimming crabs as well as preparation method and application of intercropping biological fermented feed

A technology for biologically fermenting feed, white shrimp, applied in animal feed, animal feed, bacteria used in food preparation, etc., can solve the problem of unsuccessful shelling of white shrimp and swimming crab, low efficiency of animal digestion, absorption and utilization, and influence on breeding. efficiency and other issues, to achieve the effect of improving yield and disease resistance, saving labor costs, and optimizing water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

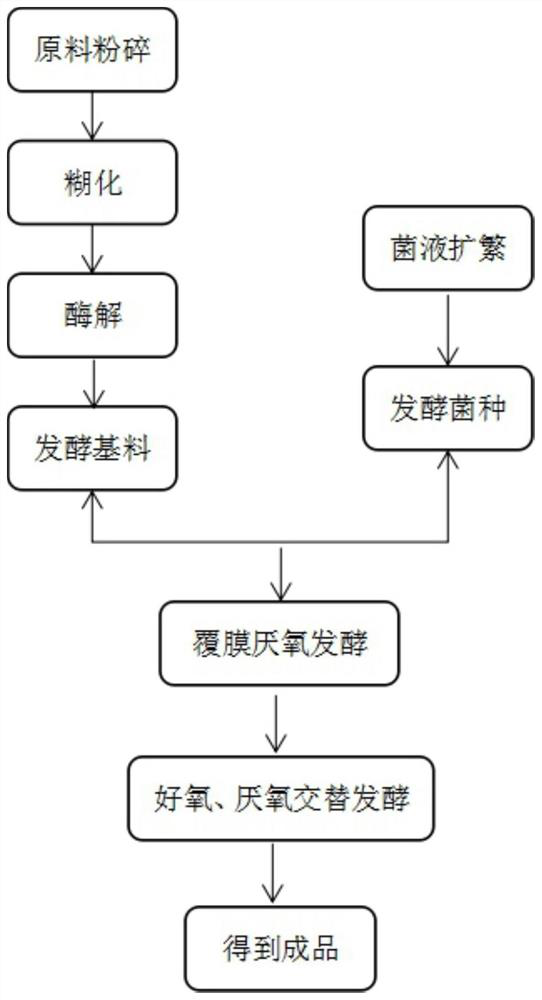

Method used

Image

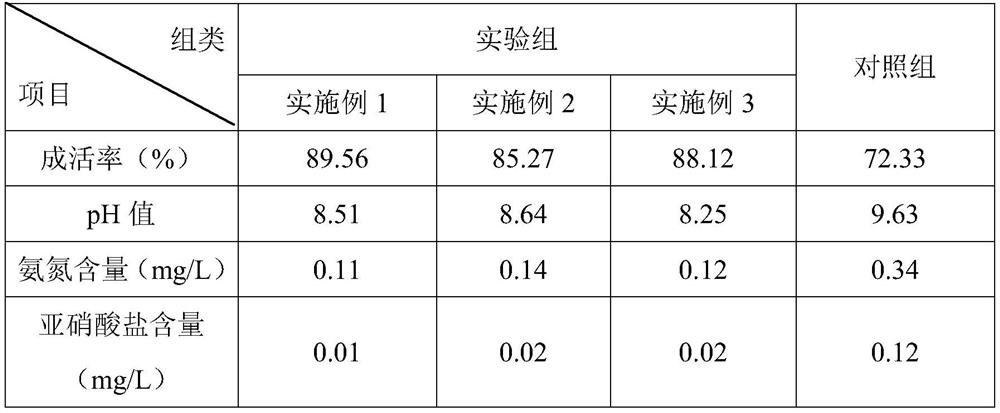

Examples

Embodiment 1

[0045] The white shrimp of the present embodiment, the portunus cover culture biological feed are made by following method:

[0046] 1) Grinding 38 parts of corn, 30 parts of soybean meal, 10 parts of wheat bran, 12 parts of spirulina and 15 parts of rice bran in parts by weight, and passing through a 80-mesh sieve;

[0047] 2) 12 parts by weight of fish meal, 3 parts of fish oil, 6 parts of squid paste, 6 parts of shrimp shell powder, 12 parts of stone powder, 4 parts of calcium dihydrogen phosphate, and the mixture in step 1) Add them together into a mixer and mix them evenly, then put them into an autoclave for curing, 0.15MPa, curing temperature 121°C, curing time 50min;

[0048] 3) After the mixture in step 2) is cooled, spray the compound enzyme that is 0.25 parts by weight to the mixture, and stir while spraying, so as to mix evenly; wherein the compound enzyme is composed of trypsin, amylase, lipase, serum lysozyme Enzymes are mixed according to the weight ratio of 5:...

Embodiment 2

[0054] The white prawn of the present embodiment, swimming crab cover raise biological feed to be made by following method:

[0055] 1) Grinding 35 parts of corn, 25 parts of soybean meal, 8 parts of wheat bran, 8 parts of spirulina and 10 parts of rice bran in parts by weight, and passing through a 90-mesh sieve;

[0056] 2) By weight, 8 parts of fish meal, 2 parts of fish oil, 2 parts of squid paste, 3 parts of shrimp shell powder, 8 parts of stone powder, 2 parts of calcium dihydrogen phosphate, and the mixture in step 1) Add them together into the mixer and mix them evenly, then put them into a high-pressure sterilizer for curing, 0.15MPa, curing temperature 121°C, curing time 55min;

[0057] 3) After the mixture in step 2) is cooled, spray the compound enzyme that is 0.15 parts by weight to the mixture, and stir while spraying to make the mixture uniform; wherein the compound enzyme is composed of trypsin, amylase, lipase, serum lysozyme Enzymes are mixed according to th...

Embodiment 3

[0063] The white shrimp of the present embodiment, the portunus cover culture biological feed are made by following method:

[0064] 1) Grinding 40 parts of corn, 35 parts of soybean meal, 9 parts of wheat bran, 15 parts of spirulina and 12 parts of rice bran in parts by weight, and passing through a 100-mesh sieve;

[0065] 2) 10 parts by weight of fish meal, 3 parts of fish oil, 4 parts of squid paste, 5 parts of shrimp shell powder, 10 parts of stone powder, 3 parts of calcium dihydrogen phosphate, and the mixture in step 1) Add them together into a mixer and mix them evenly, then put them into an autoclave for curing, 0.15MPa, curing temperature 121°C, curing time 60min;

[0066] 3) After the mixture in step 2) is cooled, spray the compound enzyme that is 0.20 parts by weight to the mixture, and stir while spraying to make the mixture evenly; wherein, the compound enzyme is composed of trypsin, amylase, lipase, serum Lysozyme is made by mixing according to the weight rati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com