Catalyst loading inverse opal carbon nitride with carbon defect with titanium carbide quantum dots and preparation method of catalyst

A technology of carbon nitride and titanium carbide, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as unfavorable photocatalytic reactions, increase specific surface area, improve light collection and Utilization, the effect of improving migration and separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

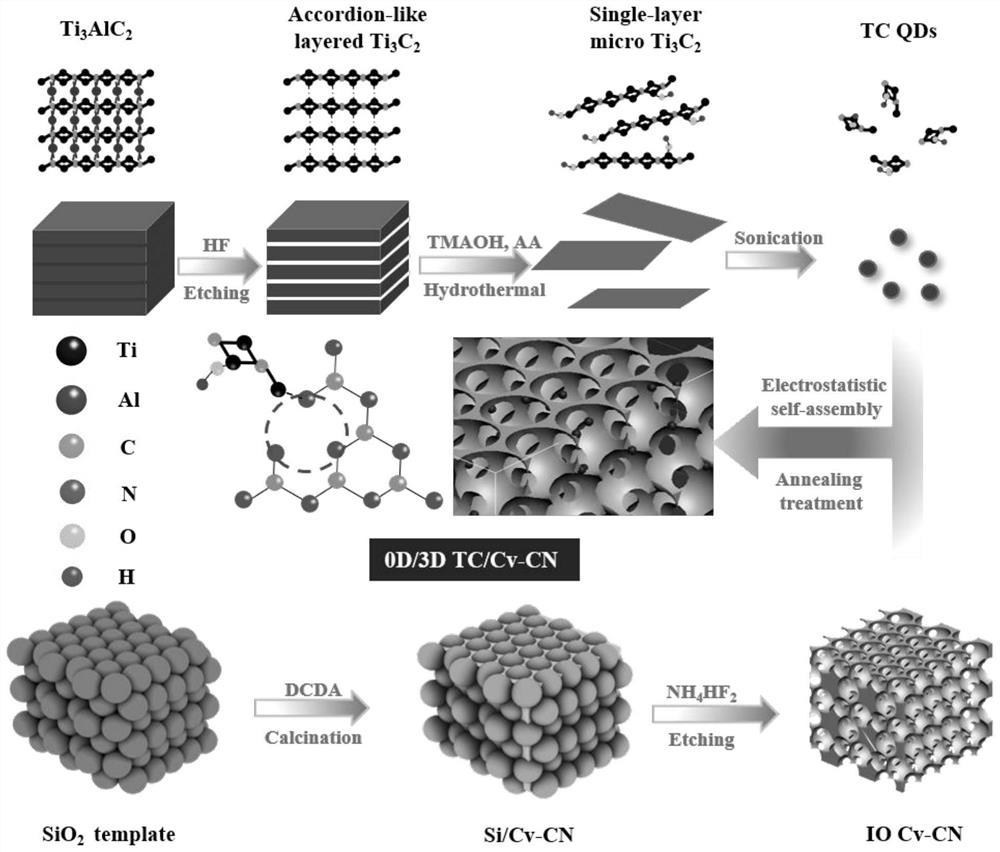

[0047] Preparation of TC / Cv-CN:

[0048] Titanium aluminum carbide (Ti 3 AlC 3 ) was dispersed in hydrofluoric acid, stirred in an oil bath at 60°C for 24 hours, washed and dried to obtain titanium carbide (Ti 3 C 2 );

[0049] 200mg of titanium carbide, 4.8mL of tetramethylammonium hydroxide (TMAOH), 0.7044g of sodium ascorbate and 56.2ml of H 2 O was added into a 100mL hydrothermal kettle for hydrothermal reaction. The hydrothermal reaction temperature was 160°C and the reaction time was 24h. After ultrasonic crushing and dialysis, a light yellow titanium carbide quantum dot aqueous solution (TC) was obtained. Inserted at the interface of the accordion layer, destroying the potential Ti-Ti bond and the residual Ti-Al bond, thereby separating into a single-layer sheet; ascorbic acid protects titanium carbide from being oxidized under high temperature and high pressure.

[0050] Cv-CN (50 mg) obtained in Comparative Example 2 was mixed with 20 mL of titanium carbide quant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com