Photo-thermal responsive drug carrier based on nano titanium nitride and microcapsule and preparation method

A nano-titanium nitride and photothermal response technology, applied in the field of nano-materials, can solve the problem of high cost of use, and achieve the effects of high precision, simple preparation process, and high drug loading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

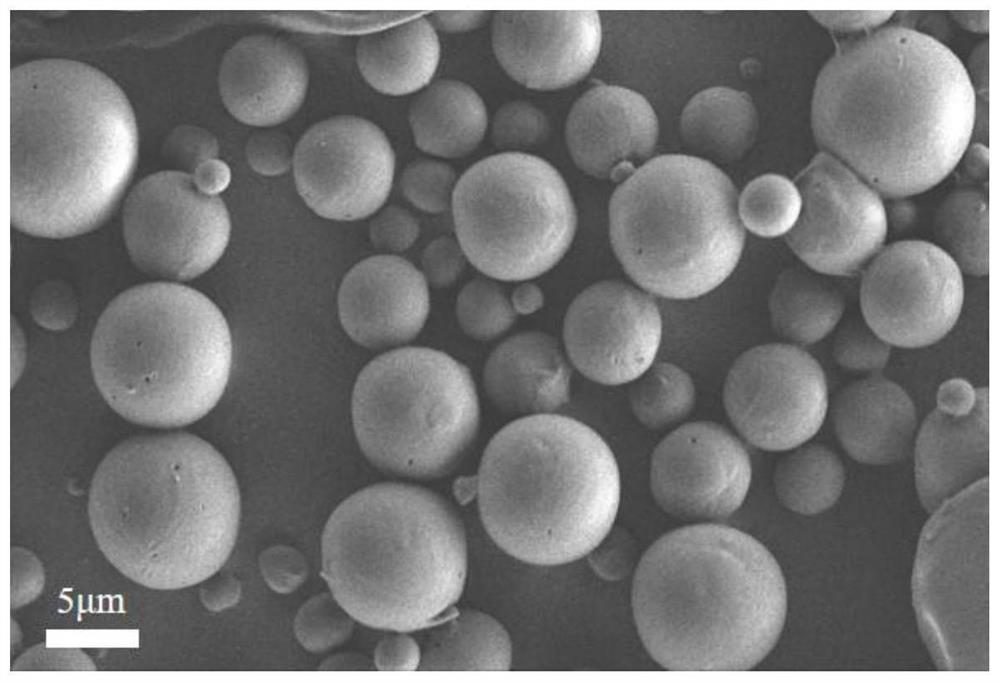

[0022] 1. Using polyvinyl alcohol aqueous solution as the "outer water phase", 8-hydroxyquinoline and polyε-caprolactone dissolved in dichloromethane as the "inner oil phase", through magnetic stirring, centrifugation, washing, and freeze-drying Methods Polyε-caprolactone-8-hydroxyquinoline drug-loaded microcapsules were prepared.

[0023] 2. Add 0.3g of sodium hydroxide to a mixed solution of 20mL of deionized water and 80mL of absolute ethanol, then add 0.5g of microcapsules, and ultrasonically oscillate for 5 minutes to hydrolyze the ester groups on the surface of the microcapsules under alkaline conditions. for surface carboxylation.

[0024] 3. Centrifuge the above solution at 3000rpm for 5 minutes, wash twice with deionized water at 5000rpm for 5 minutes, and freeze-dry the solid matter obtained by centrifugation for 18 hours to obtain drug-loaded microcapsules with carboxylated surfaces.

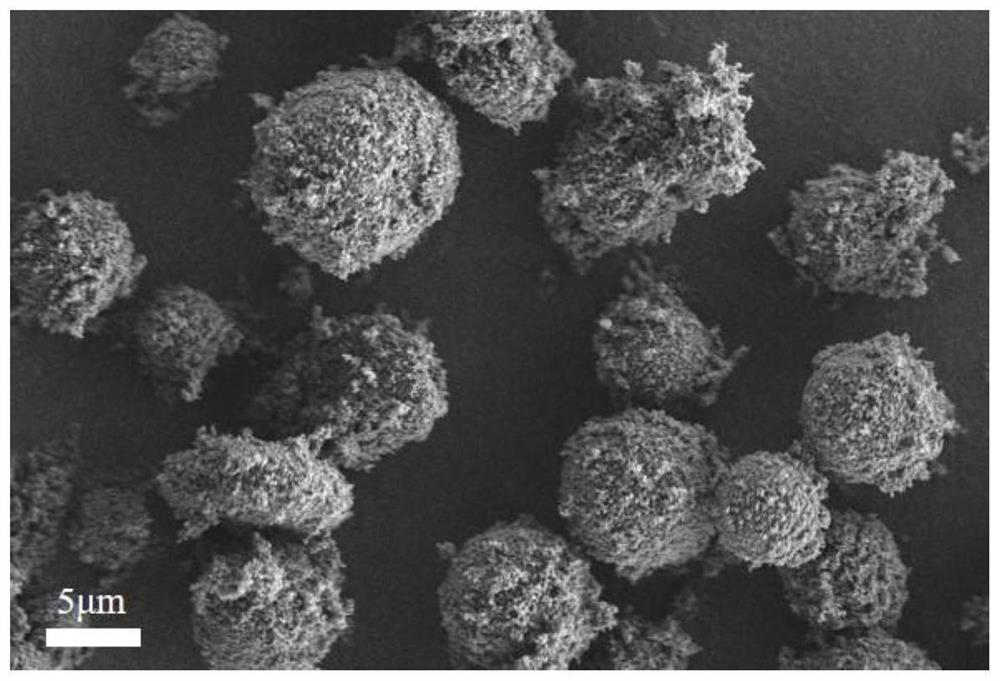

[0025] 4. Add 0.1g of nano-titanium nitride particles into 20mL of deionized wat...

Embodiment 2

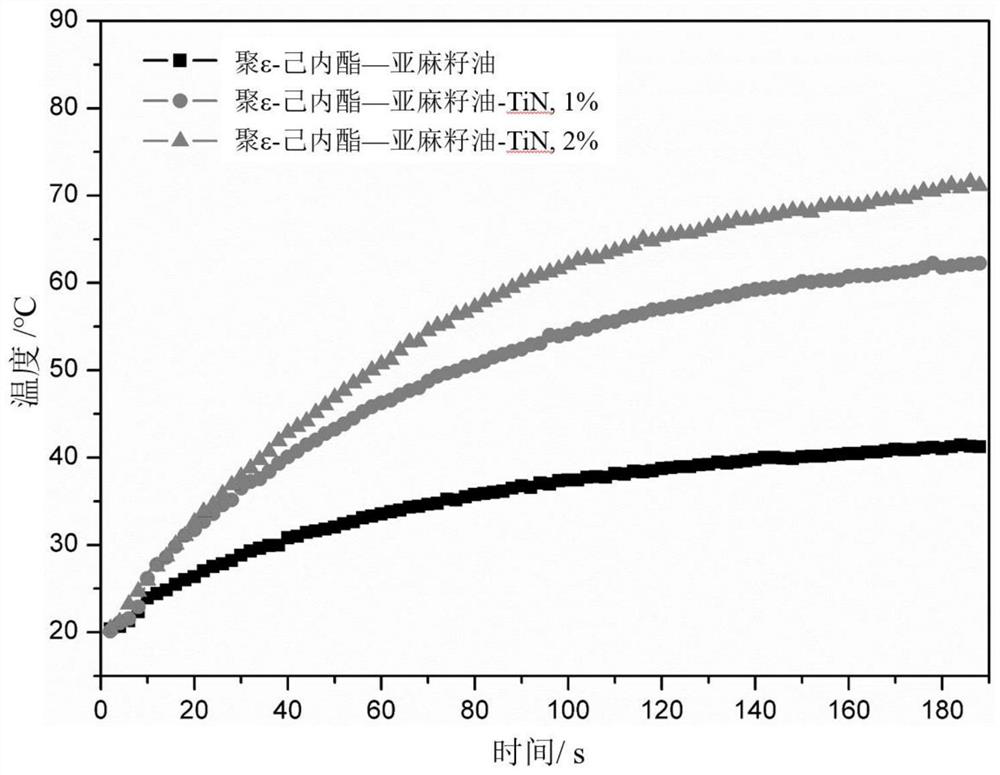

[0031] 1. Using polyvinyl alcohol aqueous solution as the "outer water phase", linseed oil and polyε-caprolactone dissolved in dichloromethane as the "inner oil phase", prepared by magnetic stirring, centrifugation, washing, and freeze-drying Polyε-caprolactone-linseed oil-loaded microcapsules.

[0032] 2. Add 2.0g of sodium hydroxide to a mixed solution of 30mL of deionized water and 70mL of absolute ethanol, then add 1.0g of microcapsules, and ultrasonically oscillate for 20 minutes to hydrolyze the ester groups on the surface of the microcapsules under alkaline conditions. for surface carboxylation.

[0033] 3. Suction filter the above solution, wash twice with deionized water, freeze-dry the solid matter obtained by suction filtration for 24 hours, and obtain drug-loaded microcapsules with surface carboxylation.

[0034] 4. Add 0.3g of nano-titanium nitride particles into 40mL of deionized water, use a cell pulverizer to sonicate for 1 hour, then add 140mL of absolute eth...

Embodiment 3

[0040] 1. Using polyvinyl alcohol aqueous solution as the "outer water phase", laurylamine and polyε-caprolactone dissolved in dichloromethane as the "inner oil phase", prepared by magnetic stirring, centrifugation, washing, and freeze-drying Polyε-caprolactone-dodecylamine drug-loaded microcapsules.

[0041] 2. Add 3.0g of sodium hydroxide to a mixed solution of 20mL of deionized water and 100mL of absolute ethanol, then add 2.0g of microcapsules, and ultrasonically oscillate for 5 minutes to hydrolyze the ester groups on the surface of the microcapsules under alkaline conditions. for surface carboxylation.

[0042] 3. Centrifuge the above solution at 3000rpm for 5min, wash twice with deionized water at 5000rpm for 5min, and freeze-dry the solid matter obtained by centrifugation for 36h to obtain drug-loaded microcapsules with carboxylated surfaces.

[0043] 4. Add 0.5g of nano-titanium nitride particles into 30mL of deionized water, use a cell pulverizer to sonicate for 1h,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com