Modified polyester resin and preparation method and application thereof

A technology for modifying polyester and polyester resin, applied in the field of coatings, which can solve the problems of decreased storage stability of water-based polyester resin coatings, poor storage stability of water-based coating products, and high surface tension, so as to achieve good storage stability and improve storage Stability, effect of simple storage conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] One embodiment of the present invention also provides a method for preparing a modified polyester resin, comprising the following steps S10-S20.

[0065] Step S10: performing polycondensation reaction of at least two polyols and at least two polybasic acids to obtain a polyester resin;

[0066] Wherein, at least one of the above-mentioned at least two polybasic acids is selected from fatty dimer acids with 30 to 60 carbon atoms; based on the total mass of polybasic acids, fatty dimer acids with 30 to 60 carbon atoms The mass percentage is 5%-35%; at least one of the above-mentioned at least two polyols contains branched chains with 1-4 carbon atoms.

[0067] In some embodiments of the cycle, the reaction condition of the above polycondensation reaction is: react at 200°C-250°C for 4h-6h.

[0068] It can be understood that the polycondensation reaction method for synthesizing polyester can be any one of methods such as solvent azeotropic dehydration method, melt polycon...

specific Embodiment

[0093] Here are examples of the modified polyester resin according to the present invention, its preparation method and application, but the present invention is not limited to the following examples.

[0094] Unless otherwise specified, all raw materials used are commercially available products.

Embodiment 1

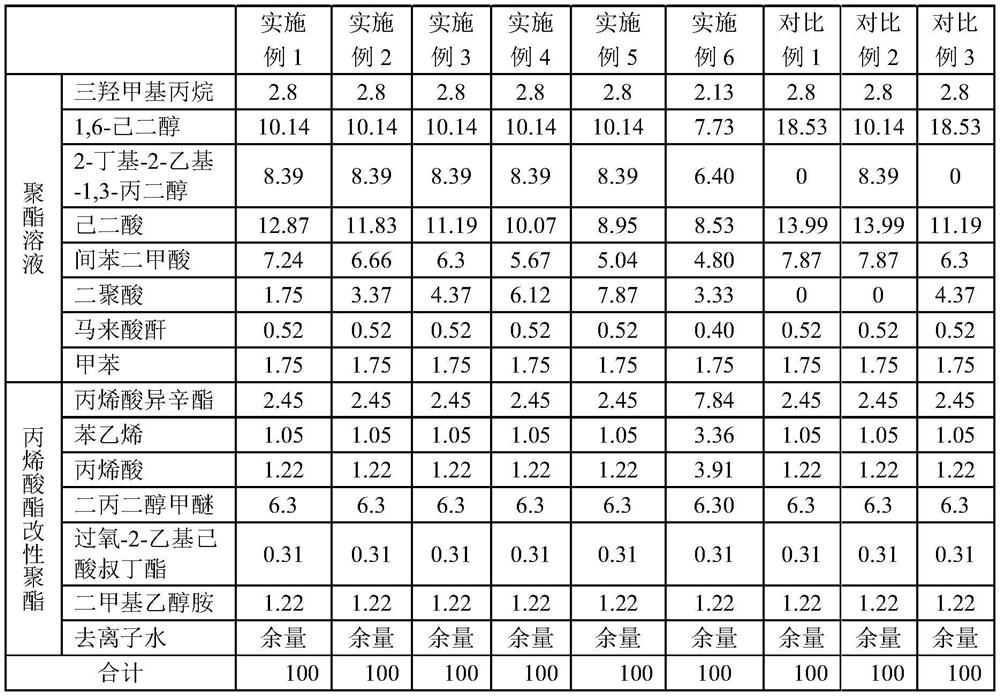

[0096] 2.80 parts of trimethylolpropane, 10.14 parts of 1,6-hexanediol, 8.39 parts of 2-butyl-2-ethyl-1,3-propanediol, 12.87 parts of adipic acid, 7.24 parts of isophthalic acid, 1.75 parts of dimer acid and 0.52 parts of maleic anhydride are placed in a reactor equipped with a thermometer, a thermostat, a stirrer, a heating device and a rectification tower, and the temperature is raised to 160°C under the protection of nitrogen, and the mixer is started when the materials start to melt Mix on low speed. Then, the temperature was raised to 230°C at a constant speed in 4 hours, and after the heat preservation polycondensation reaction for 1.5 hours, the rectification tower was switched to a water separator, and 1.75 parts of toluene was added to disperse into a polyester solution. Stop feeding nitrogen, turn on the vacuum device to remove by-product water, cool down to below 80°C and discharge, the acid value of the obtained polyester solution is 4.6mgKOH / g, and the number aver...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com