NiMn MOF as well as preparation method and application thereof

A technology of hydrothermal method and naphthalene dicarboxylic acid, applied in chemical instruments and methods, nanotechnology for materials and surface science, inorganic chemistry, etc., can solve the problems of complicated preparation process and unfriendly environment, and achieve a certain specific surface area Adjustable, shape-controllable, and composition-controllable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038]A preparation method of NiMn MOF includes the following steps:

[0039]1) Mix 2,6-naphthalenedicarboxylic acid and deionized water according to the ratio of the amount of substances to 0.05:1, adjust the pH to 8, and ultrasonicate for 30 minutes to obtain solution A;

[0040]2) Add nickel nitrate and manganese acetate to solution A in a ratio of 1:1.5, where the ratio of nickel nitrate to 2,6-naphthalenedicarboxylic acid is 1:2, ultrasonic for 30min to get mixed Solution B;

[0041]3) Transfer the mixed solution B to the reaction kettle and put it in the oven, and hydrothermally react at 80℃ for 5h. After the reaction, filter with suction and wash with deionized water for three times. After freeze-drying, the linear manganese MOF grown flake nickel MOF is obtained. The bimetal MOF.

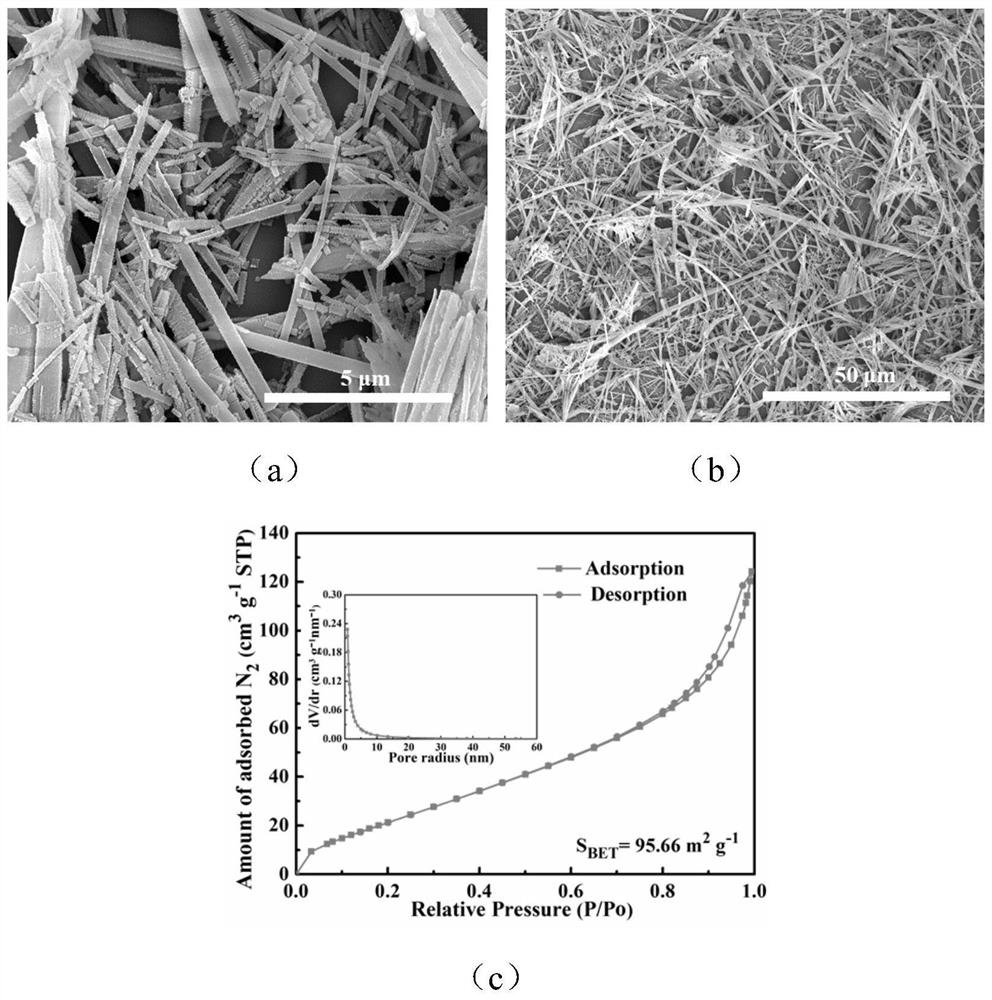

[0042]Seefigure 1 The bimetal MOF prepared by the hydrothermal reaction in this embodiment is a NiMn MOF in which a linear strip-shaped manganese MOF grows a sheet-shaped nickel MOF. The length of the NiMn ...

Embodiment 2

[0044]A preparation method of NiMn MOF includes the following steps:

[0045]1) Mix 2,6-naphthalenedicarboxylic acid and deionized water according to the ratio of the amount of substances to 0.1:1, adjust the pH to 9, and ultrasonicate for 30 minutes to obtain solution A;

[0046]2) Add nickel acetate and manganese acetate to solution A in a ratio of 1:2, where the ratio of nickel acetate to 2,6-naphthalenedicarboxylic acid is 1:2.5, ultrasonic for 30min to get the mixture Solution B;

[0047]3) Transfer the mixed solution B to the reaction kettle and put it in the oven, and hydrothermally react at 100°C for 5 hours. After the reaction is completed, it is suction filtered and washed with deionized water three times. After freeze-drying, a linear ribbon-shaped manganese MOF bonded flake is obtained Bimetallic MOF of nickel MOF.

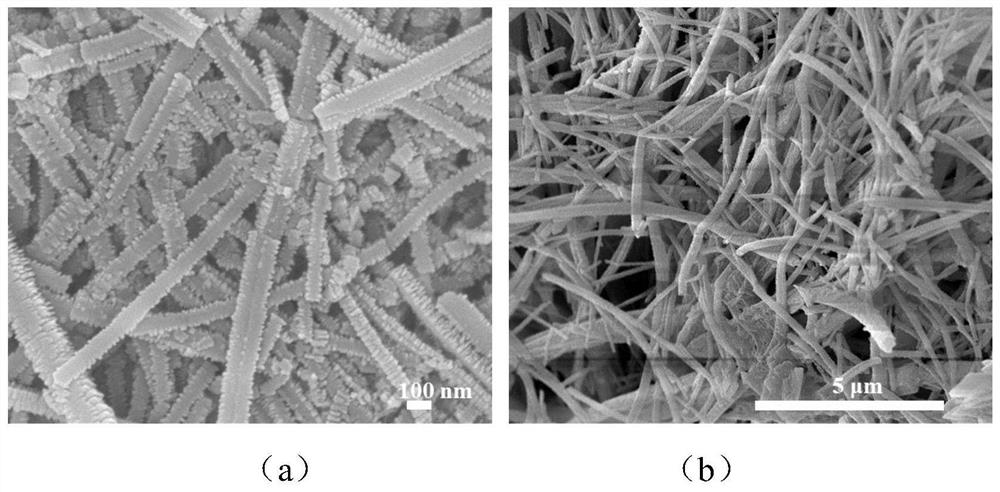

[0048]The NiMn MOF prepared by the hydrothermal reaction in this embodiment is a NiMn MOF obtained by growing flake nickel MOF with linear band-shaped manganese MOF. Th...

Embodiment 3

[0050]A preparation method of NiMn MOF includes the following steps:

[0051]1) Mix 1,5-dipotassium naphthalate and deionized water according to the ratio of the amount of substances to 0.15:1, adjust the pH to 10, and ultrasound for 30 minutes to obtain solution A;

[0052]2) Add nickel sulfate and manganese sulfate to solution A according to the substance amount ratio of 1:1.6, where the substance amount ratio of nickel sulfate to 1,5-dipotassium naphthalate is 1:2.2, ultrasonic for 30min Obtain mixed solution B;

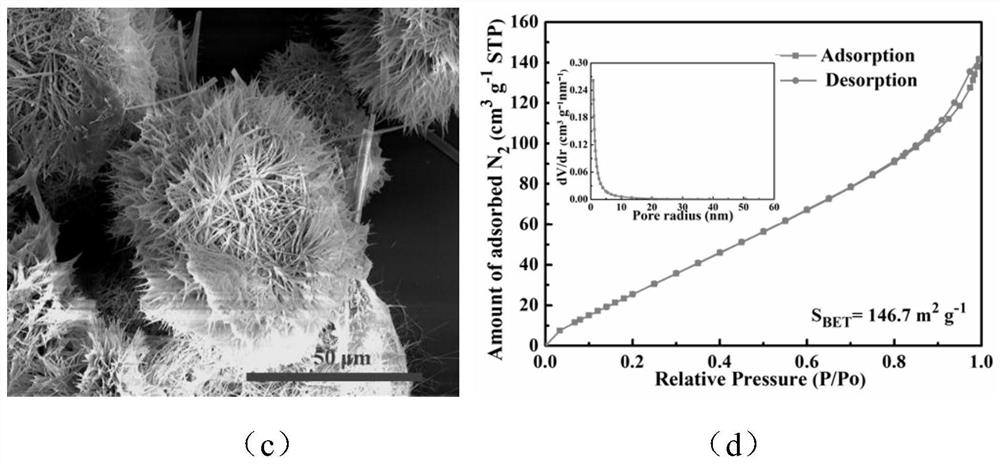

[0053]3) Transfer the mixed solution B to the reactor and put it in the oven, and hydrothermally react at 90°C for 10 hours. After the reaction, it is filtered off with suction and washed with deionized water three times. After freeze-drying, a linear ribbon-shaped manganese MOF growth sheet is obtained. Bimetallic MOF of nickel MOF. The NiMn MOF prepared by the hydrothermal reaction in this embodiment is a NiMn MOF obtained by growing flake nickel MOF with linear band-shaped ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com