Environment-friendly anti-cracking waterproof agent for concrete and preparation method thereof

An anti-cracking waterproofing agent, environment-friendly technology, applied in the field of environment-friendly anti-cracking waterproofing agent for concrete and its preparation, can solve the problems of poor concrete impermeability and inability to improve the environment, achieve high-efficiency photocatalytic performance, improve Density, the effect of improving crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

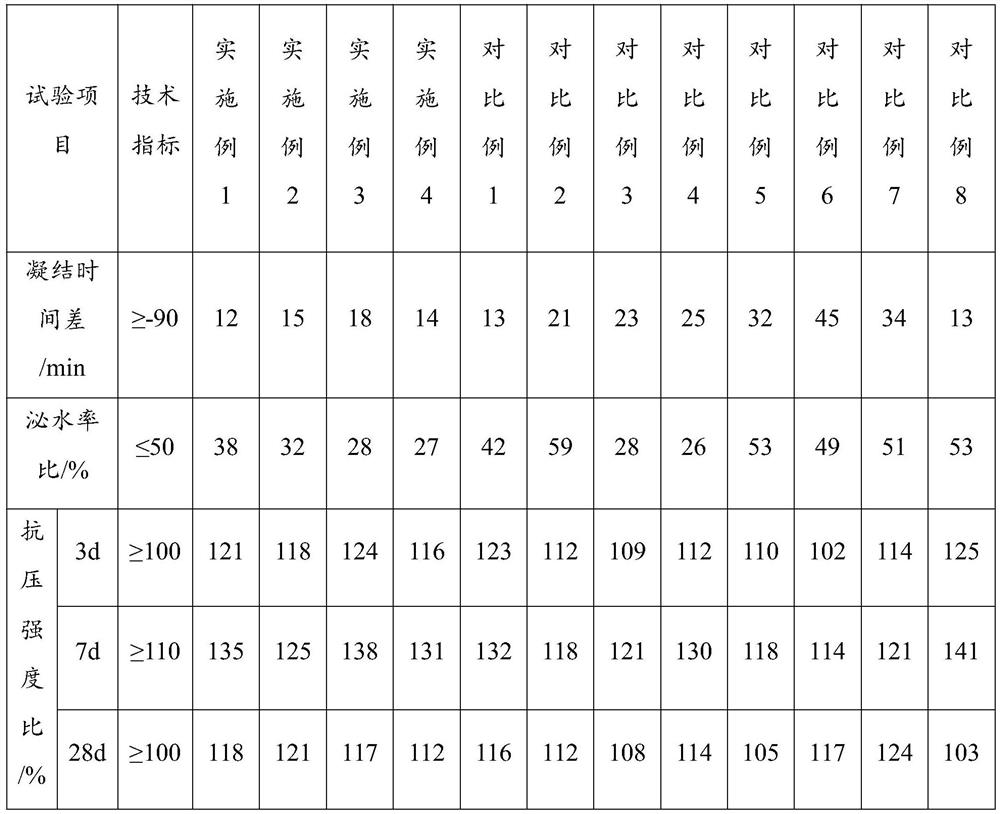

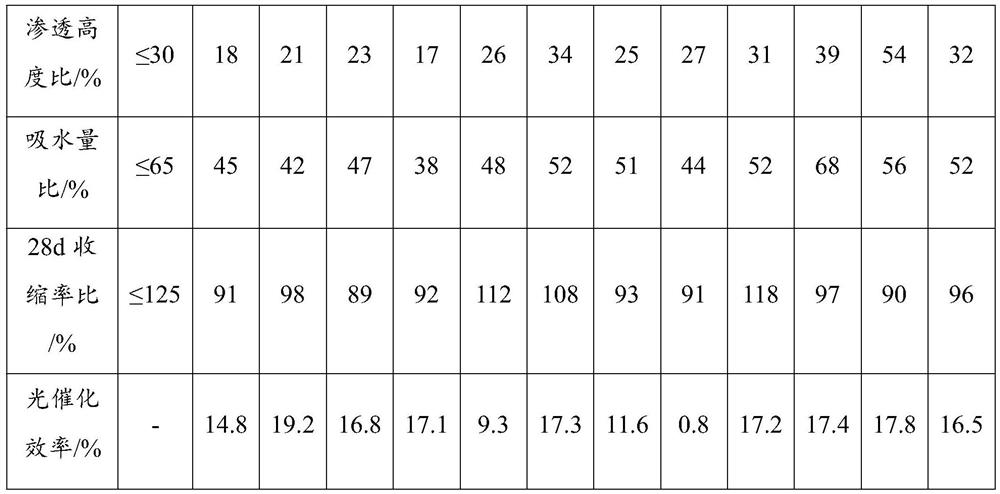

Embodiment 1

[0029] This embodiment provides an environmentally friendly anti-cracking and waterproofing agent for concrete, which is composed of the following components by mass percentage: 1% of graphite phase carbon nitride nanosheets, 20% of modified phosphogypsum powder, and 30% of ultrafine lithium slag powder , nano-titanium dioxide 5%, bauxite 5%, modified bentonite 22.5%, magnesia expansion agent 5%, silicone zirconium 5%, silicone water repellent 5%, high alkali-resistant water-absorbing resin 0.5%, poly Carboxylic acid superplasticizer 1%. The finished anti-cracking and waterproofing agent is obtained after the above-mentioned components are uniformly mixed mechanically.

Embodiment 2

[0031] This embodiment provides an environmentally friendly anti-cracking and waterproofing agent for concrete, which is composed of the following components by mass percentage: 3% of graphite phase carbon nitride nanosheets, 5% of modified phosphogypsum powder, and 10% of ultrafine lithium slag powder , nano-titanium dioxide 10%, bauxite 5%, modified bentonite 50%, magnesia expansion agent 5%, silicone zirconium 2%, silicone water repellent 5%, high alkali-resistant water-absorbing resin 2%, poly Carboxylic acid superplasticizer 3%. The finished anti-cracking and waterproofing agent is obtained after the above-mentioned components are uniformly mixed mechanically.

Embodiment 3

[0033] This embodiment provides an environment-friendly anti-cracking and waterproofing agent for concrete, which is composed of the following components by mass percentage: 2% graphite phase carbon nitride nanosheets, 10% modified phosphogypsum powder, and 20% ultrafine lithium slag powder , nano-titanium dioxide 5%, bauxite 10%, modified bentonite 30%, magnesia expansion agent 10%, silicone zirconium 2%, silicone water repellent 5%, high alkali-resistant water-absorbing resin 3%, poly Carboxylic acid superplasticizer 3%. The finished anti-cracking and waterproofing agent is obtained after the above-mentioned components are uniformly mixed mechanically.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com