Degradable cassava acetate starch, resin thereof, and preparation and application of degradable cassava acetate starch and resin thereof

A technology of acetate starch and cassava flour, which is applied in the field of degradable cassava acetate starch, its resin and the preparation and application of the two, can solve white pollution, hinder the comprehensive promotion and application of degradable materials, and plastic products cannot Degradation and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

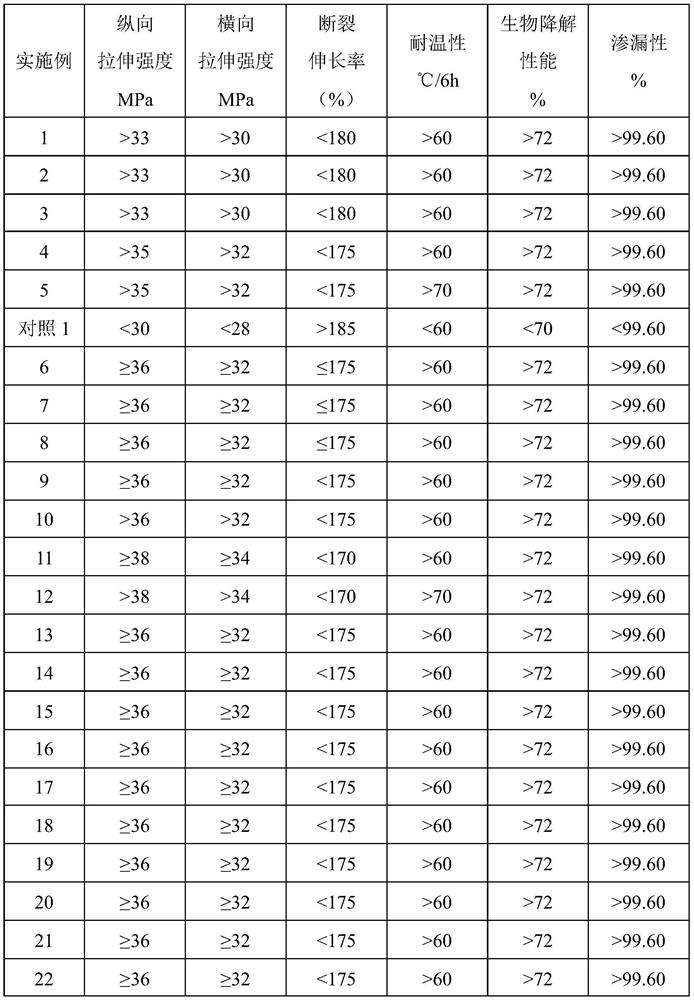

Examples

preparation example Construction

[0127] Preferably, the preparation method of described degradable cassava acetate starch comprises the steps:

[0128] Step (1): Weigh deionized water and tapioca starch according to the formula and pour them into container 1 sequentially, and heat up and stir, the temperature is controlled within the range of 44-46°C, keep warm and stir;

[0129] Step (2): Weigh sodium hydroxide according to the formula, and dilute it with deionized water and inject it dropwise into container 1 for alkalization treatment;

[0130] Step (3): after step (2), add hydrogen peroxide and / or sodium hypochlorite dropwise to container 1 within the temperature range of 44-46° C., and continue to insulate and stir;

[0131] Step (4): After step (3) is finished, add acetic anhydride dropwise to container 1 within the temperature range of 44-46° C., and keep stirring;

[0132] Step (5): After step (4) is finished, take another acetic anhydride, add acetic anhydride dropwise to container 1 within the rang...

Embodiment 1

[0198] Tapioca acetate starch recipe:

[0199] Tapioca starch: 36%

[0200] Acetic anhydride: 7%

[0203] Deionized water: 52%:

[0204] All the above are percentages by mass.

[0205] Degradable cassava acetate starch resin formula:

[0206] Tapioca acetate starch: 67.2%;

[0207] Plasticizer epoxy soybean oil (ESO): 28.8%;

[0208] Stabilizer dimethyl tin mercaptide (referred to as 181): 0.5%;

[0209] Degradant ethylene glycol (EG): 1.5%

[0210] Cross-linking agent dicumyl peroxide (DCP): 0.8%;

[0211] Lubricant Oleamide: 1.2%;

[0212] All the above are percentages by mass.

Embodiment 2

[0213] Embodiment 2: tapioca acetate starch formula is identical with embodiment 1, and degradable tapioca acetate starch resin formula is based on embodiment 1, and tapioca acetate starch increment is 1.5%, and plasticizer plasticizer epoxy soybean oil decreases The amount is 1.5%, and the others remain unchanged;

[0214] Tapioca acetate starch: 68.7%;

[0215] Plasticizer epoxy soybean oil (ESO): 27.3%;

[0216] Stabilizer dimethyl tin mercaptide (referred to as 181): 0.5%;

[0217] Degradant ethylene glycol (EG): 1.5%

[0218] Cross-linking agent dicumyl peroxide (DCP): 0.8%;

[0219] Lubricant Oleamide: 1.2%;

[0220] All the above are percentages by mass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Heat resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com