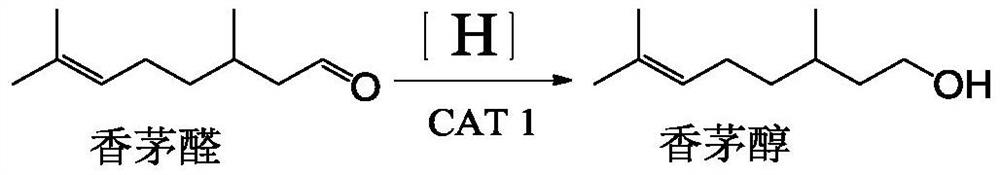

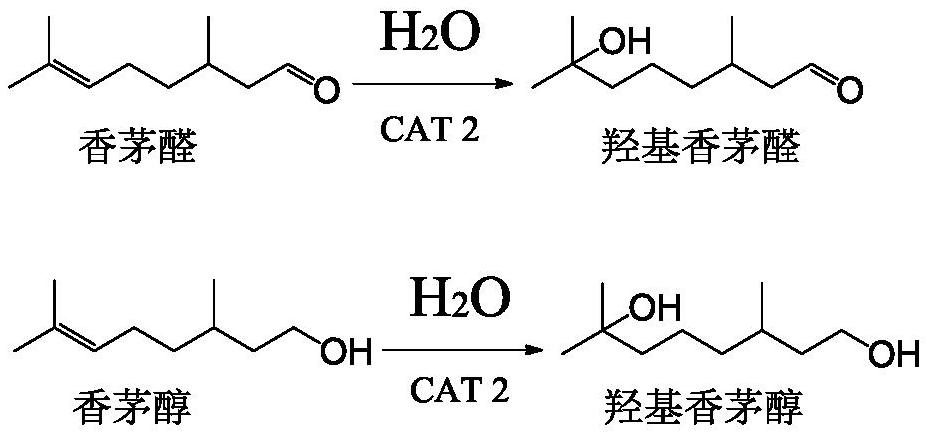

Method for co-producing hydroxycitronellal and hydroxycitronellol

A technology of hydroxycitronellol and hydroxycitronellal, which is applied in chemical instruments and methods, preparation of hydroxy compounds, production of bulk chemicals, etc., can solve unsatisfactory technical methods, harsh reaction conditions, low conversion rate, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

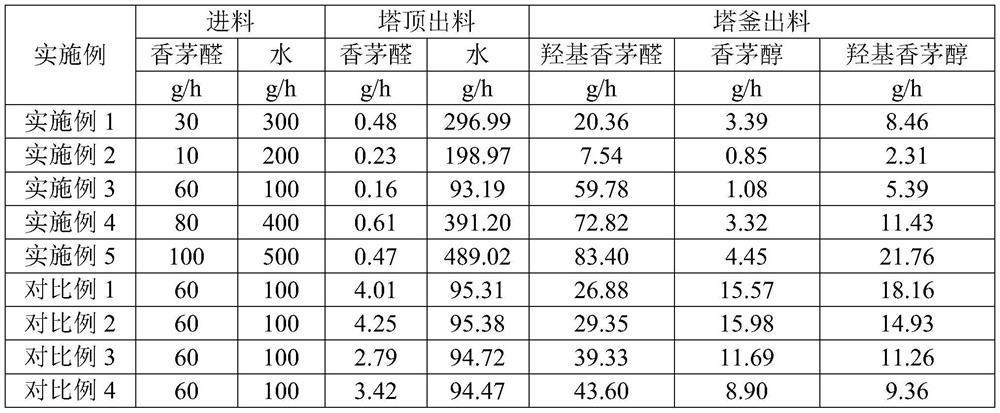

Examples

Embodiment 1

[0072] Cobalt oxide preparation:

[0073] a) Mix cobalt acetate, isopentyl glycol and triethylamine in a molar ratio of 1:1:2, place in an autoclave, heat up to 150°C in an airtight manner, separate solid and liquid after 8 hours of heat preservation, and obtain nano-cobalt oxide after drying. The diameter is 57nm, and the average surface roughness (Ra) is 1.43nm.

[0074] Preparation of hydrogenation catalyst CAT1:

[0075] a) 0.30g FeCl 3 , 10.47g RuCl 3 Dissolve in 20g of water, stir well until completely dissolved, and make impregnating solution;

[0076] b) adding the impregnation solution prepared in a) dropwise to 100 g of nano-cobalt oxide until the end of the dropwise addition, and completing the equal-volume impregnation of the metal salt solution;

[0077] c) roasting the mixture obtained in step b) at 500° C. under a nitrogen atmosphere for 5 hours, and then lowering to room temperature after the roasting is completed, to obtain a cobalt oxide-supported catalys...

Embodiment 2

[0093] Cobalt oxide preparation:

[0094] a) Mix cobalt acetate, isopentyl glycol and triethylamine at a molar ratio of 1:1.7:2.7, place in an autoclave, heat up to 170°C in a closed manner, separate solid and liquid after keeping warm for 2 hours, and obtain nano-cobalt oxide after drying. The diameter is 83nm, and the average surface roughness (Ra) is 2.8nm. ;

[0095] Preparation of hydrogenation catalyst CAT1:

[0096] a) 0.89g FeCl 3 , 8.37g RuCl 3 Dissolve in 20g of water, stir well until completely dissolved, and make impregnating solution;

[0097] b) adding the impregnation solution prepared in a) dropwise to 100 g of nano-cobalt oxide until the end of the dropwise addition, and completing the equal-volume impregnation of the metal salt solution;

[0098] c) Calcining the mixture obtained in step b) at 560° C. under a nitrogen atmosphere for 12 hours, and then lowering to room temperature after the roasting is completed, to obtain a cobalt oxide-supported catalys...

Embodiment 3

[0113] Cobalt oxide preparation:

[0114] a) Mix cobalt acetate, isopentyl glycol and triethylamine at a molar ratio of 1:2.6:3.6, place in an autoclave, heat up to 220°C in a sealed manner, separate solid and liquid after heat preservation for 14 hours, and obtain nano-cobalt oxide after drying. The diameter is 61nm, and the average surface roughness (Ra) is 2.3nm;

[0115] Preparation of hydrogenation catalyst CAT1:

[0116] a) 1.77g FeCl 3 , 6.28g RuCl 3 Dissolve in 20g of water, stir well until completely dissolved, and make impregnating solution;

[0117] b) adding the impregnation solution prepared in a) dropwise to 100 g of nano-cobalt oxide until the end of the dropwise addition, and completing the equal-volume impregnation of the metal salt solution;

[0118] c) roasting the mixture obtained in step b) at 620° C. under a nitrogen atmosphere for 16 hours, and then lowering to room temperature after the roasting is completed, to obtain a cobalt oxide-supported catal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Average roughness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com