Anti-mud polycarboxylic acid water reducing agent and preparation method thereof

A technology of polycarboxylic acid series and water reducing agent, which is applied in the field of polycarboxylate water reducing agent for concrete, can solve the problem of reducing concrete water reducing rate and slump retention performance, increasing the content of PCE water reducing agent, and prolonging the setting time of concrete. and other problems, to achieve the effect of reducing surface adsorption, avoiding adverse effects, and easy control of reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

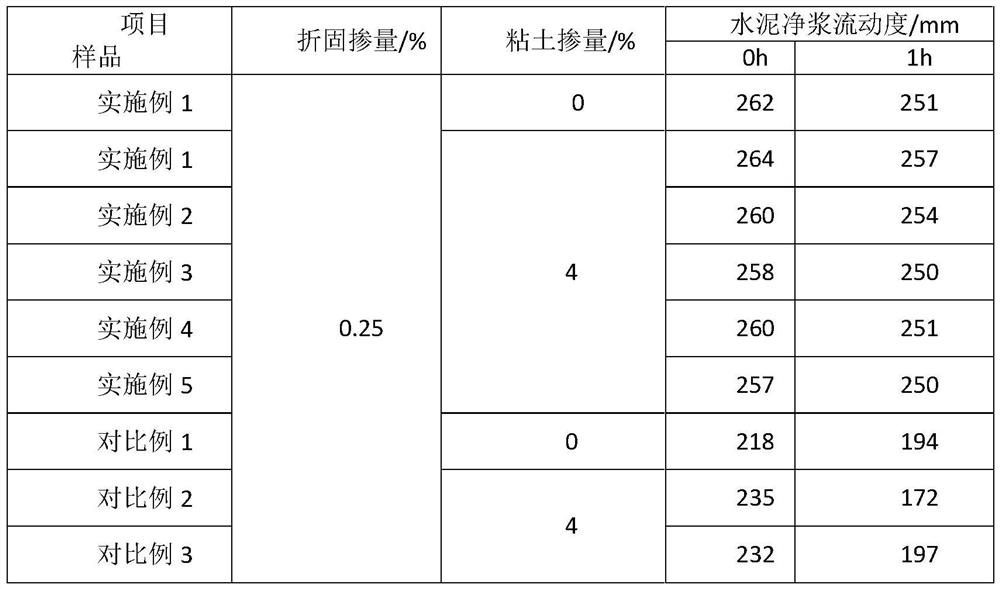

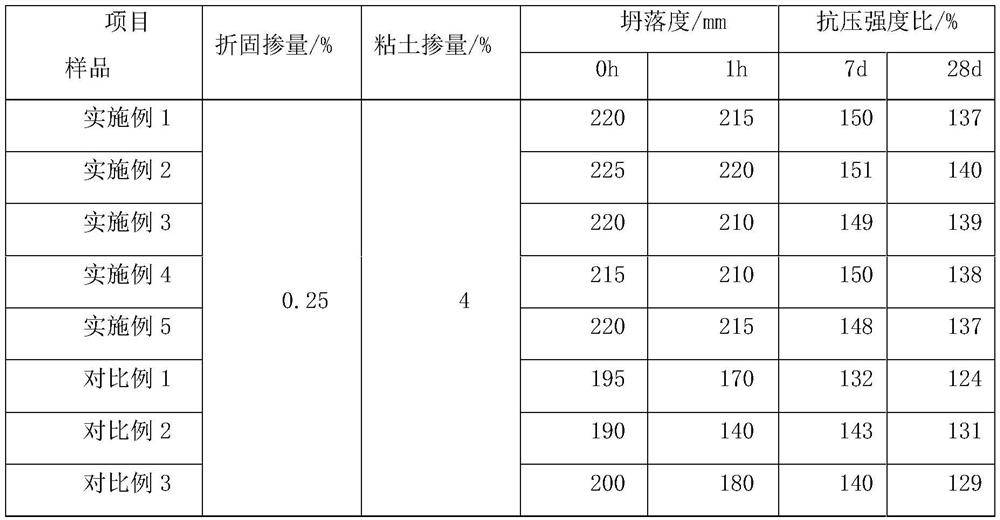

Examples

preparation example Construction

[0034] The preparation method of the above-mentioned anti-mud type polycarboxylate water reducer comprises the following steps:

[0035] Step 1, dissolving the multi-arm polymer precursor in part of dimethyl sulfoxide to form a bottom solution;

[0036] Step 2, dissolving methacrylic polyethylene glycol ether, unsaturated acid monomer, acryloyloxyethyltrimethylammonium chloride, and chain transfer agent in part of dimethyl sulfoxide to form material A;

[0037] Step 3, dissolving the initiator in part of dimethyl sulfoxide to form material B;

[0038] Step 4: Warm up the base material to 62°-68°, start to add A and B materials dropwise at a constant speed, and keep warm for 3.0 hours under the condition of 62°-68° after the dropwise addition;

[0039] Step 5: After the heat preservation is completed, cool the solution to room temperature, dialyze to remove impurities, and then remove the solvent to obtain a mud-resistant polycarboxylate superplasticizer.

[0040] The prepara...

Embodiment 1

[0045]Dissolve polyvinyl alcohol in dimethyl sulfoxide at 50°C to form a PVA solution with a concentration of 2%, add acryloyl chloride twice the mass of polyvinyl alcohol and an appropriate amount of concentrated sulfuric acid into the PVA solution, and reflux at 50°C for 3 hours After stopping the reaction. Pour the solution into a beaker filled with water, precipitate out, filter with suction, wash, and dry in a vacuum oven to obtain a multi-arm polymer precursor. Dissolve 6.5 parts of the multi-arm polymer precursor in part of dimethyl sulfoxide to form a base liquid, and chlorinate 28 parts of methacrylic polyglycol ether, 22 parts of acrylic acid, and 13 parts of acryloyloxyethyl trimethyl Ammonium, 1.2 parts of 2,4-diphenyl-4-methyl-1-pentene are dissolved in part of dimethyl sulfoxide to form material A, and 0.9 parts of dibenzoyl peroxide are dissolved in part of dimethyl sulfoxide Form material B in the sulfone, raise the temperature of the base material to 65±3°, s...

Embodiment 2

[0047] Dissolve polyvinyl alcohol in dimethyl sulfoxide at 50°C to form a PVA solution with a concentration of 3%, add acryloyl chloride twice the mass of polyvinyl alcohol and an appropriate amount of concentrated sulfuric acid into the PVA solution, and reflux at 50°C for 3 hours After stopping the reaction. Pour the solution into a beaker filled with water, precipitate out, filter with suction, wash, and dry in a vacuum oven to obtain a multi-arm polymer precursor. Dissolve 8 parts of the multi-arm polymer precursor in part of dimethyl sulfoxide to form a base liquid, and 30 parts of methacrylic acid polyglycol ether, 20 parts of methacrylic acid, 10 parts of acryloyloxyethyltrimethyl Ammonium chloride and 0.8 parts of isooctyl 3-mercaptopropionate are dissolved in part of dimethyl sulfoxide to form material A, and 1.5 parts of dibenzoyl peroxide are dissolved in part of dimethyl sulfoxide to form material B. Heat up the base material to 65±3°, start dropping A and B mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com