Sodium metal negative electrode deposition substrate and preparation method and application thereof

A sodium metal and matrix technology is applied in the field of sodium metal anode deposition matrix and its preparation, which can solve the problems of harsh preparation conditions and poor stability of sodium anode, and achieve the effects of low experimental equipment requirements, low energy consumption, and stable deposition/stripping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] As introduced in the background technology, there are problems in the prior art that the sodium metal negative electrode has poor stability under high current density, or the preparation conditions are harsh. In order to solve this technical problem, the first aspect of the present invention provides a sodium metal negative electrode The preparation method of the deposition matrix comprises the following steps: first preparing porous graphene, and then preparing the sodium metal deposition matrix by scraping or rolling.

[0025] The steps of the scraping method are: mix porous graphene powder and sodium alginate (CMC) according to a certain ratio, add an appropriate amount of water to grind into a slurry, then scrape and coat the current collector with a scraper, cut into circles after drying sheet, the sodium metal deposition matrix is obtained.

[0026] The steps of the rolling method are as follows: fresh metal sodium is cut into small pieces in a glove box filled ...

Embodiment 1

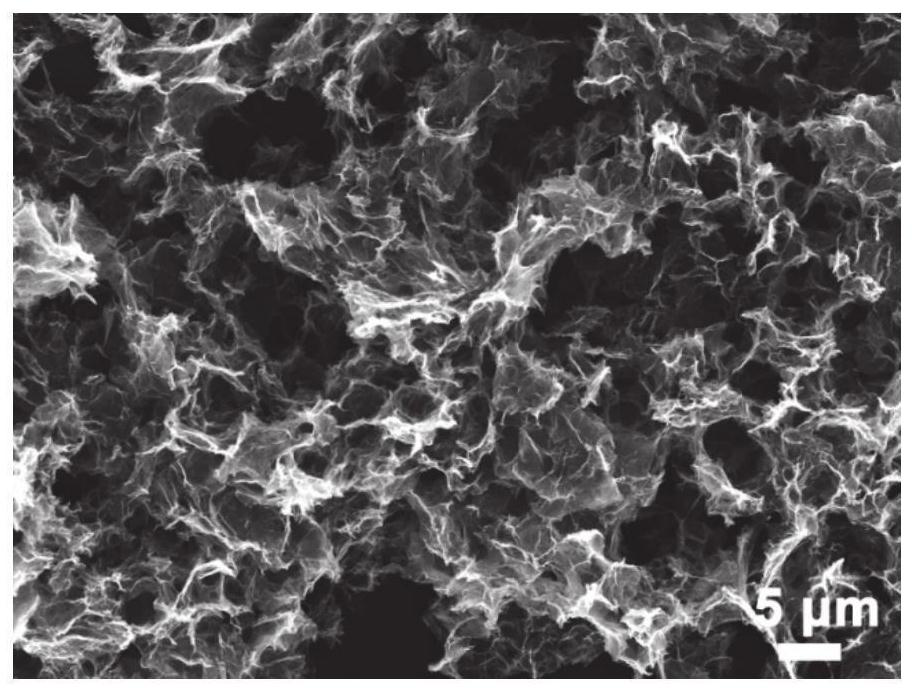

[0056] The preparation steps of porous graphene are:

[0057] 1) Under constant stirring, add 3g of graphite into 70mL of concentrated sulfuric acid, then add 1.5g of sodium nitrate, and stir well. Control the temperature below 20°C, and slowly add 9g of potassium permanganate in batches.

[0058] 2) Transfer the beaker containing the above solution to a water bath at 35°C, and stir for 30 minutes to form a viscous shape. Then 500mL of water was added, stirred for 15min, and 12mL of hydrogen peroxide was slowly added until the color changed from brown to yellow. Precipitate, centrifuge, use 250mL1.2mol L -1 Hydrochloric acid washed and washed repeatedly with water, then centrifuged and dialyzed for a week.

[0059] 3) Take out the dialyzed substance, prepare a 2mg / mL solution, measure 50mL, add 5mL hydrogen peroxide, and keep stirring in an oil bath at 100°C for 4h. Then the above mixture was centrifuged, washed several times with water, and dispersed into a 2 mg / mL porous...

Embodiment 2

[0062] Sodium metal deposition matrix prepared by doctor blade method:

[0063] The porous graphene powder prepared in Example 1 is mixed with sodium alginate (CMC) according to the ratio of 9:1 in mass ratio, and an appropriate amount of water is added to grind it into a slurry, which is then scraped and coated on copper foil with a scraper, after drying Cut into discs with a diameter of 12mm to obtain the sodium metal deposition matrix.

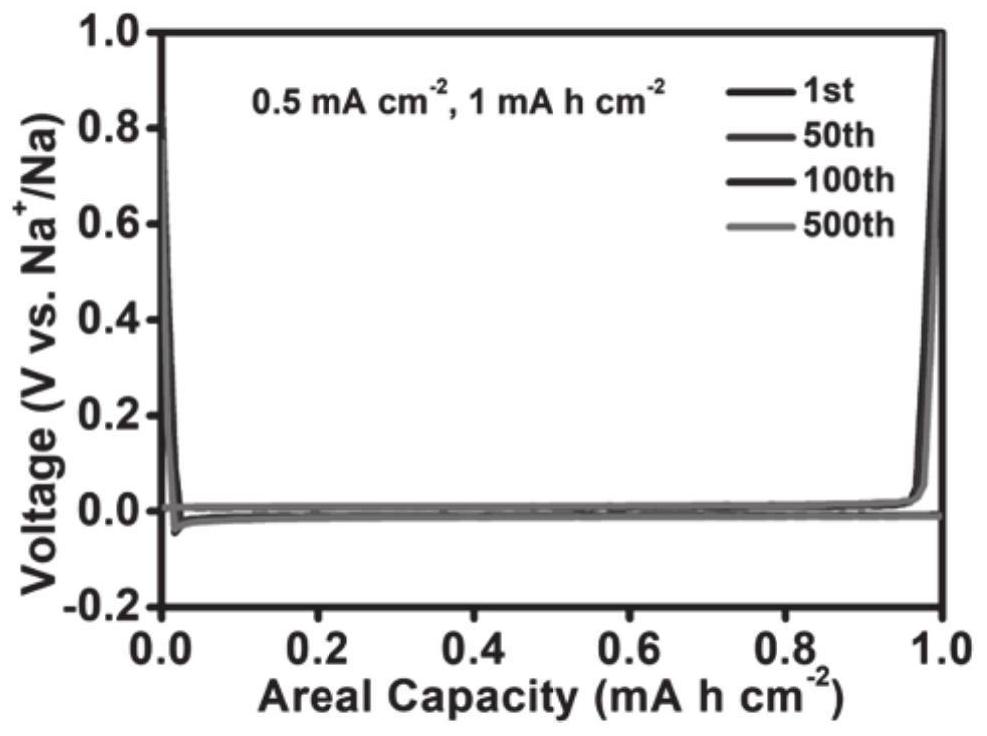

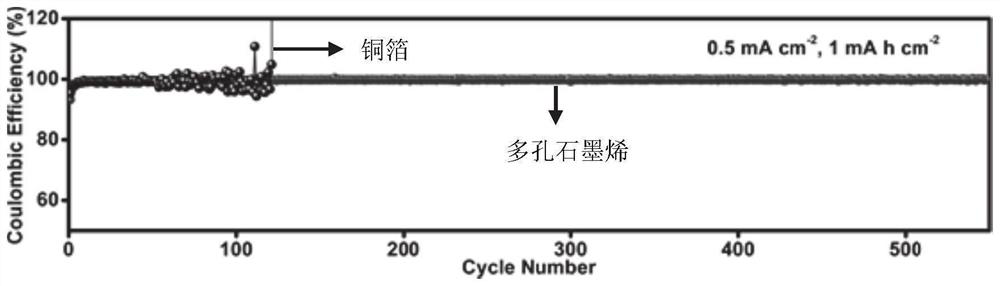

[0064] Assembly and testing of half cells:

[0065] The prepared sodium metal deposition matrix was used as the positive electrode, and the metal sodium sheet was used as the negative electrode, and a CR2032 button battery was assembled in a glove box. The electrolyte was 1M sodium hexafluorophosphate dissolved in diethylene glycol dimethyl ether (1M NaPF 6 inDEGDME), the diaphragm is glass microfiber Whatman GF / F. First, cycle 5 cycles at a current of 0.05mA between 0.01-1V (a small current cycle can remove impurities on the surface an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com