A composite fiber membrane for purifying CS in water and preparation method thereof

A composite fiber membrane and water purification technology, applied in chemical instruments and methods, silicon compounds, radioactive purification, etc., can solve problems such as difficult separation, secondary pollution, easy aggregation of Prussian blue powder, etc., achieve large specific surface area, occupy an area The effect of small area and strong flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

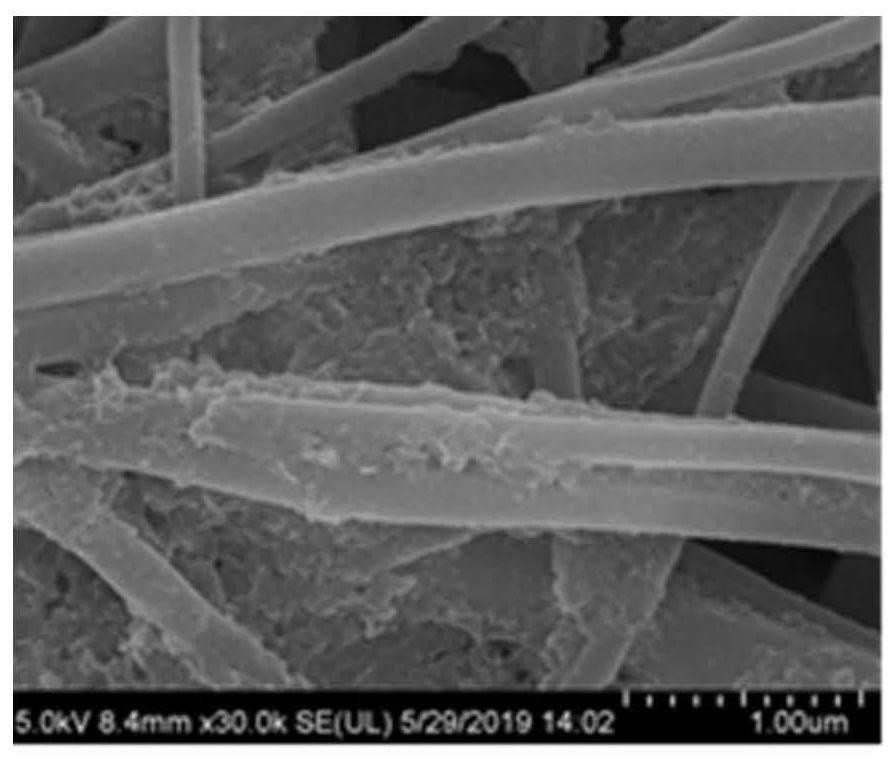

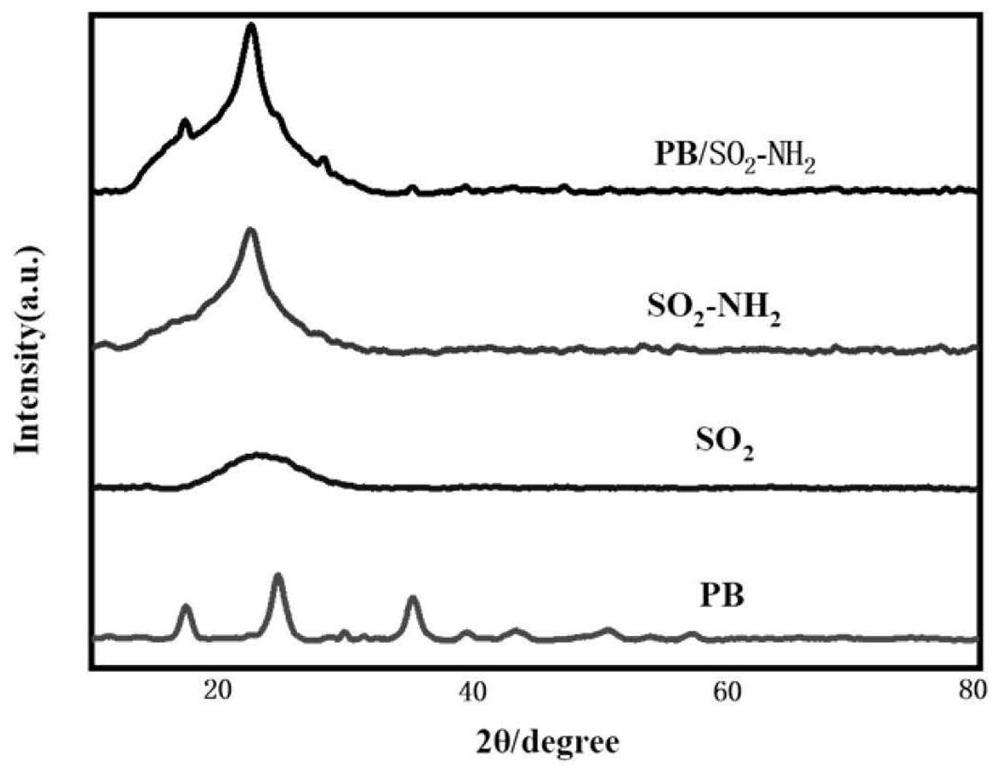

[0033] (1) Prepare a mixture of ethyl orthosilicate, ethanol, hydrochloric acid and water in a mass ratio of 1:1.65:2:0.01. The reaction temperature is 80 °C, the stirring speed is 200 r / min, and the reaction time is 120 min. Prepared SiO 2 The solution is milky white. the SiO 2 The solution was placed in a spinning device, the electrospinning voltage was 18 kV, the spinning distance was 20 cm, and the spinning time was 180 min, that is, until the aluminum foil was covered with white fibers, SiO was obtained. 2 nanofiber membrane;

[0034] (2) Prepare (30:1:1, v / v / v) mixed solution of ethanol (90% wt), HCl (37% wt) and 3-aminopropyltriethoxysilane (APTES) according to the volume ratio, It was hydrolyzed for 60 min. the SiO 2 The nanofiber membrane was placed in the silane sol and taken out after 30 min. The aminopropylsilane sol can be inhaled into the pores of the nanofiber membrane through capillary action, and the sol is condensed to form a Si-O-Si network, which is r...

Embodiment 2

[0038] (1) Prepare a mixture of ethyl orthosilicate, ethanol, hydrochloric acid, and water in a mass ratio of 1:2:2:0.01, the reaction temperature is 80 °C, the stirring speed is 200 r / min, and the reaction time is 120 min. Prepared SiO 2 The solution is milky white. the SiO 2 The solution was placed in a spinning device, the electrospinning voltage was 18 kV, the spinning distance was 20 cm, and the spinning time was 180 min, that is, until the aluminum foil was covered with white fibers, SiO was obtained. 2 nanofiber membrane;

[0039] (2) Prepare (30:1:1, v / v / v) mixed solution of ethanol (90% wt), HCl (37% wt) and 3-aminopropyltriethoxysilane (APTES) according to the volume ratio, It was hydrolyzed for 60 min. the SiO 2 The nanofiber membrane was placed in the silane sol and taken out after 30 min. The aminopropylsilane sol can be inhaled into the pores of the nanofiber membrane through capillary action, and the sol is condensed to form a Si-O-Si network, which is rep...

Embodiment 3

[0043] (1) Prepare a mixture of ethyl orthosilicate, ethanol, hydrochloric acid, and water in a mass ratio of 1:3.5:2:0.01. The reaction temperature is 80 °C, the stirring speed is 200 r / min, and the reaction time is 120 min. Prepared SiO 2 The solution is milky white. the SiO 2 The solution was placed in a spinning device, the electrospinning voltage was 18 kV, the spinning distance was 20 cm, and the spinning time was 180 min, that is, until the aluminum foil was covered with white fibers, SiO was obtained. 2 nanofiber membrane;

[0044] (2) Prepare (30:1:1, v / v / v) mixed solution of ethanol (90% wt), HCl (37% wt) and 3-aminopropyltriethoxysilane (APTES) according to the volume ratio, It was hydrolyzed for 60 min. the SiO 2 The nanofiber membrane was placed in the silane sol and taken out after 30 min. The aminopropylsilane sol can be inhaled into the pores of the nanofiber membrane through capillary action, and the sol is condensed to form a Si-O-Si network, which is r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com