Organic spin valve device based on two-dimensional metal organic framework thin film material and preparation method

A metal-organic framework and thin-film material technology, applied in the field of spintronics, can solve the problems of insufficient material system, high cost, unfavorable industrialization, etc., and achieve the effect of low equipment requirements, low cost, and reduction of difficulty and complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

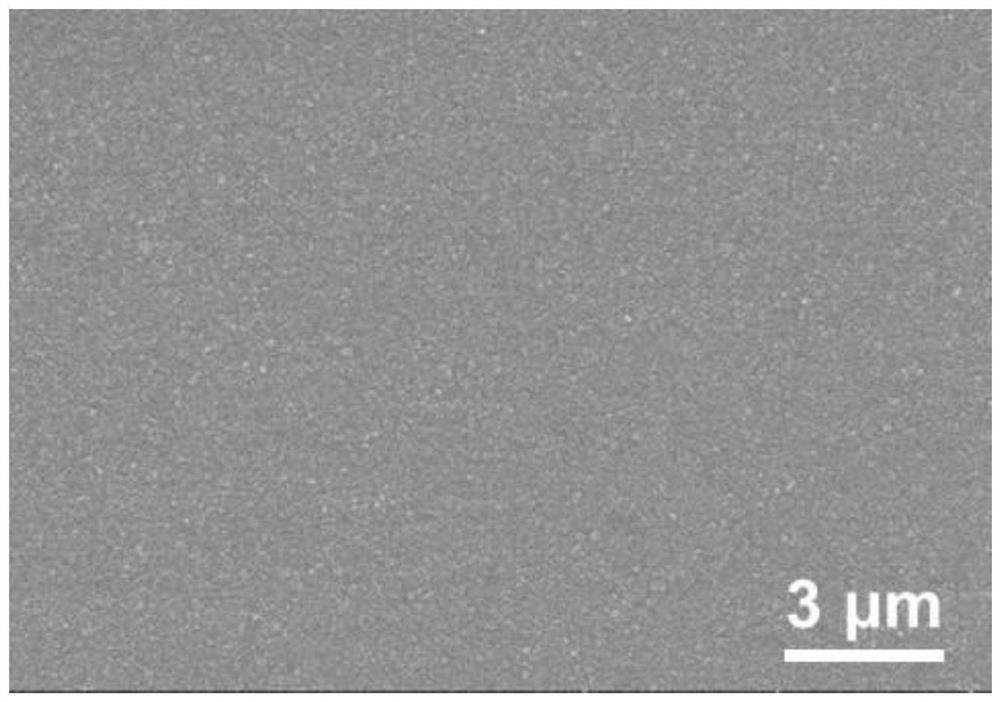

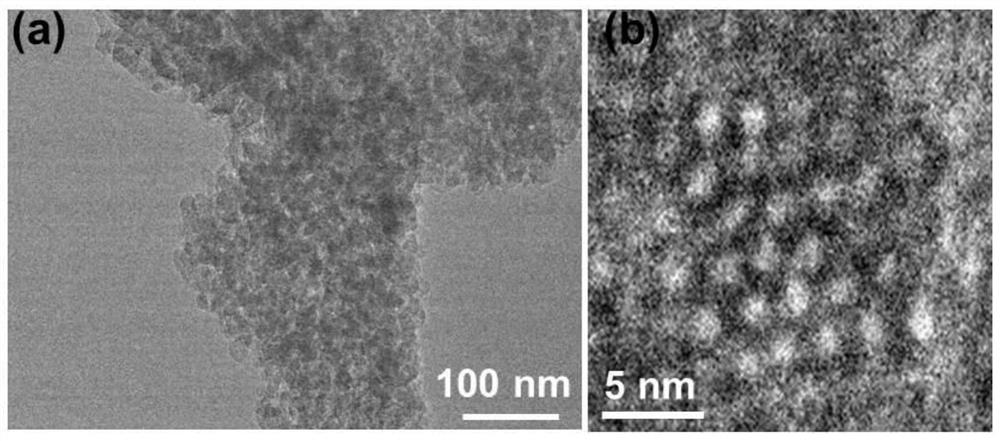

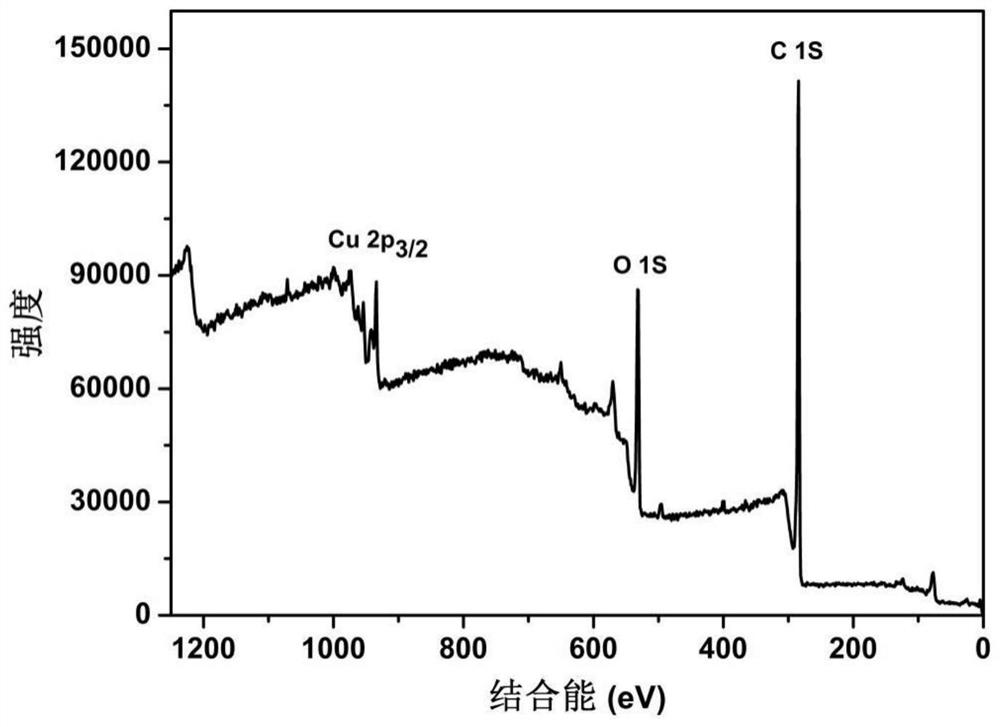

[0041] The method for preparing a two-dimensional metal-organic framework film material on a glass substrate (in order to test the properties of the two-dimensional metal-organic framework film material, it is selected to be prepared on a glass substrate), comprising the following steps:

[0042] (1) Immerse the glass substrate in deionized water and ethanol in order to ultrasonically wash and dry; then immerse in a mixed solvent (in order to adapt to the glass substrate, the mixed solvent is: by volume ratio 7:3 by H 2 SO 4 and H 2 o 2 Composition), soaked at 85°C for 30 minutes, took out, washed with deionized water and dried; immersed in (3-aminopropyl)trimethoxysilane solution with a concentration of 1% by volume, and the solvent of the silane solution was anhydrous normal Octanol, heated to reflux for 0.25 hours, taken out, washed with absolute ethanol, and dried;

[0043] (2) Copper acetate monohydrate was dissolved in absolute ethanol to obtain 0.1 mM solution A, and...

Embodiment 2

[0052] A method for preparing an organic spin valve device based on a two-dimensional metal organic framework thin film material, comprising the following steps:

[0053] (1) Cut strontium titanate (001) substrate into 0.5×0.5cm 2 A square of 200 μm × 4mm strip mask is fixed on the substrate to obtain a substrate with a strip mask. In the magnetron sputtering apparatus, the substrate provided with a strip mask is fixed on the sample Put it on, and evacuate until the vacuum degree reaches 5×10 -5 Above Pa; heat to 770°C, adjust the flow rate of high-purity argon gas to 10 sccm and the flow rate of oxygen to 6 sccm for ventilation, adjust the air pressure to 0.5 Pa, turn on the sputtering switch, adjust the radio frequency power to 120W, and sputter the lanthanum strontium manganese oxygen target. The deposition rate is 0.8nm / min, and a strontium titanate substrate with a strip-shaped lanthanum strontium manganese oxide bottom electrode deposited with a thickness of 50nm is obt...

Embodiment 3

[0062] A method for preparing an organic spin valve device based on a two-dimensional metal organic framework thin film material, comprising the following steps:

[0063] (1) Cut strontium titanate (001) substrate into 0.5×0.5cm 2 A square of 200 μm × 4mm strip mask is fixed on the substrate to obtain a substrate with a strip mask. In the magnetron sputtering apparatus, the substrate provided with a strip mask is fixed on the sample Put it on, and evacuate until the vacuum degree reaches 5×10 -5 Above Pa; heat to 800°C, adjust the flow rate of high-purity argon gas to 15 sccm and the flow rate of oxygen to 9 sccm for ventilation, adjust the air pressure to 0.8 Pa, turn on the sputtering switch, adjust the radio frequency power to 150W, and sputter the lanthanum strontium manganese oxygen target. The deposition rate is 0.8nm / min, and a strontium titanate substrate with a strip-shaped lanthanum strontium manganese oxide bottom electrode deposition thickness of 40nm is obtained;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com