Yttrium-doped nickel-zinc-cobalt ferrite and preparation method thereof

A technology of cobalt ferrite and nickel zinc, which is applied in the field of soft magnetic ferrite materials, can solve the problems of easy pollution of the environment, high cost, and long preparation cycle, and achieve no pollution in the process, low DC resistivity, improved magnetic properties and The effect of electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

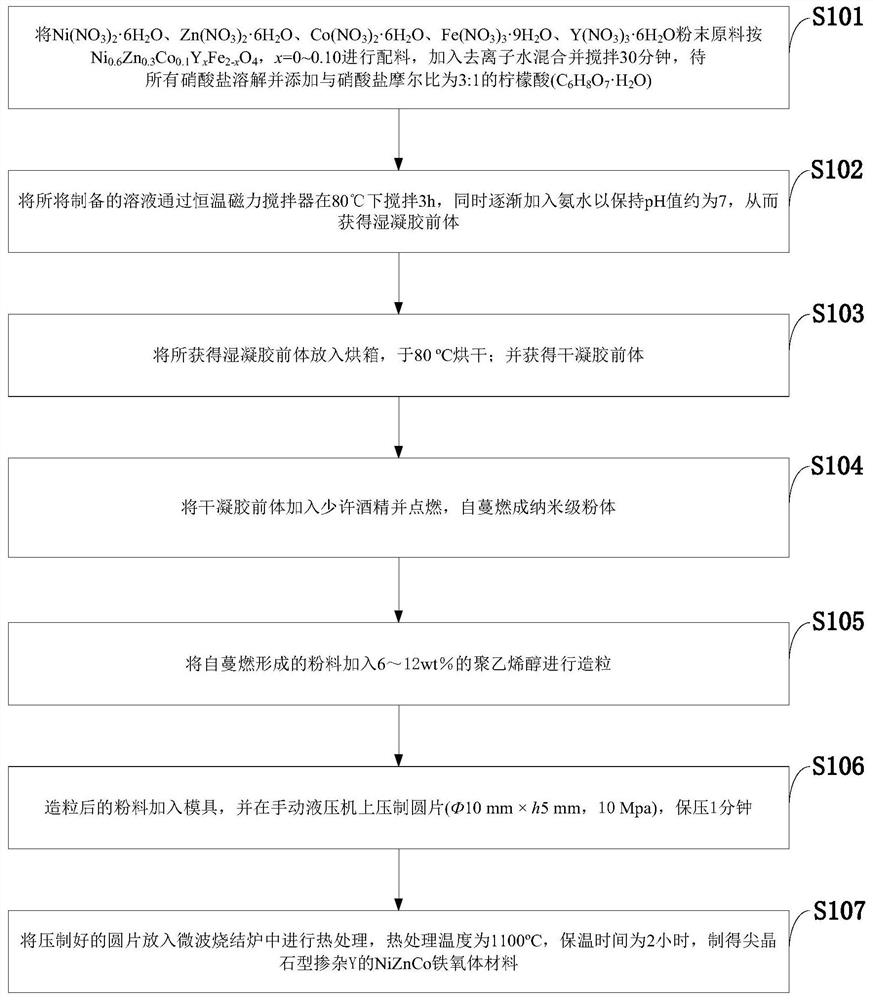

[0041] The preparation method of the nickel-zinc-cobalt ferrite doped with yttrium of the present invention comprises the steps:

[0042] a. Preparation of wet gel precursor: Mix nickel salt, zinc salt, cobalt salt, iron salt, yttrium salt and water, add citric acid after dissolving, stir and react at 70-90°C for 2-4 hours, and control the reaction system The pH value is 6.5-7.5, so as to obtain the wet gel precursor;

[0043] b. Preparing the xerogel precursor: drying the wet gel precursor to obtain the xerogel precursor;

[0044] c. Self-propagating combustion reaction: the dry gel precursor is mixed with an igniter and ignited, self-propagating into nano-scale powder, and then adding polyvinyl alcohol for granulation;

[0045] d. Billet making: the granulated powder is pressed into a billet;

[0046] e. Sintering: Sinter the blank at 1000-1200°C for 1-4 hours to obtain yttrium-doped nickel-zinc-cobalt ferrite.

[0047] The method of the present invention adopts the combi...

Embodiment 1

[0067] 1. According to Ni 0.6 Zn 0.3 co 0.1 Y 0.025 Fe 1.975 o 4 The components are batched and configured as a solution with a volume of 1L and a concentration of 0.15mol / L. Weigh Ni(NO 3 ) 2 ·6H 2 O 26.1720g, Zn(NO 3 ) 2 ·6H 2 O 13.3871g, Co(NO 3 ) 2 ·6H 2 O4.3655g, Fe(NO 3 ) 3 9H 2 O 119.6909g, Y (NO 3 ) 3 ·6H 2 0.1.4365g, 165.052g of powder in total; Add all of the above powders into a beaker, add deionized water to mix and stir for 30 minutes, until all nitrates are dissolved, and add citric acid that is 3:1 with the nitrate molar ratio;

[0068] 2. Stir the prepared solution at 80° C. for 3 hours with a constant temperature magnetic stirrer, and gradually add ammonia water to keep the pH value at about 7, so as to obtain a wet gel precursor;

[0069] 3. Put the obtained wet gel precursor into an oven and dry it at 80°C; and obtain the dry gel precursor;

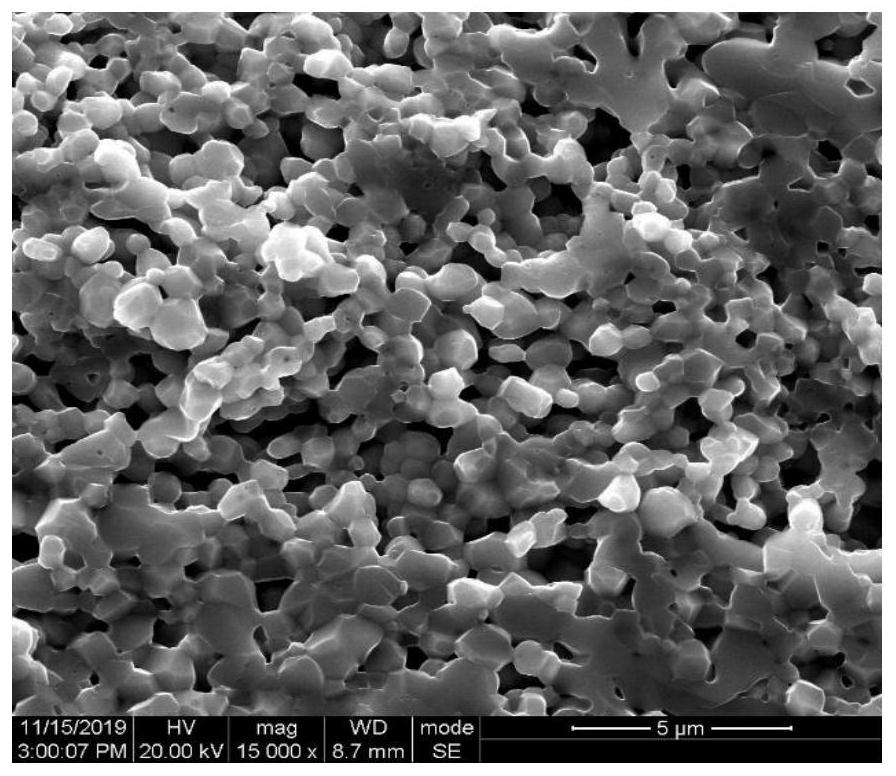

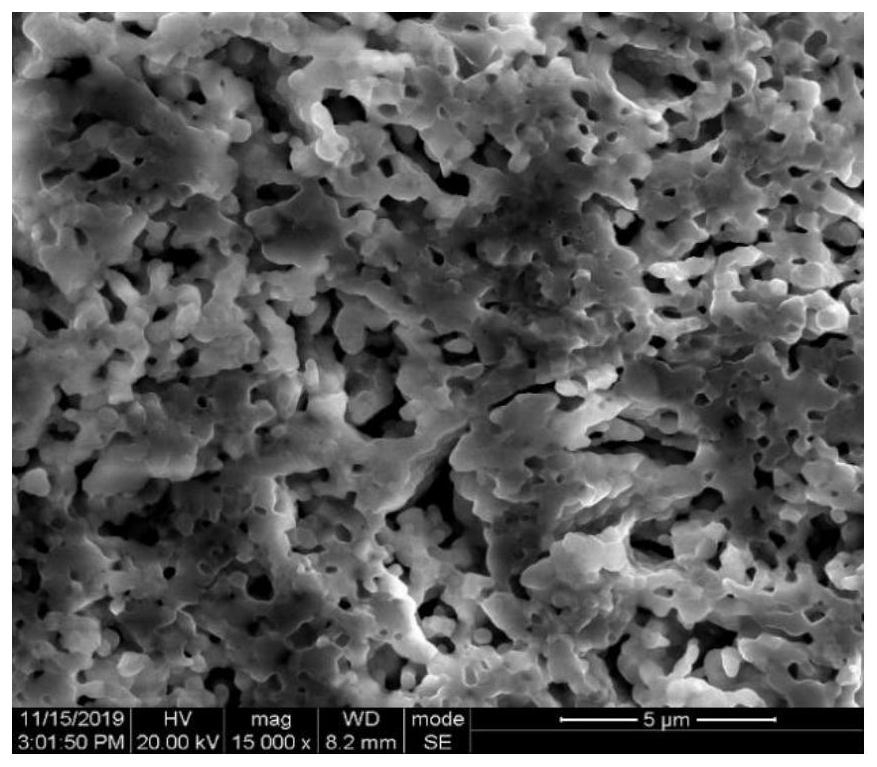

[0070] 4. Add a little alcohol to the dry gel precursor and ignite it, self-propagating combustio...

Embodiment 2

[0075] 1. According to Ni 0.6 Zn 0.3 co 0.1 Y 0.05 Fe 1.95 o 4 The components are batched and configured as a solution with a volume of 1L and a concentration of 0.15mol / L. Weigh Ni(NO 3 ) 2 ·6H 2 O 26.1720g, Zn(NO 3 ) 2 ·6H 2 O 13.3871g, Co(NO 3 ) 2 ·6H 2 O4.3655g, Fe(NO 3 ) 3 9H 2 O 118.1759g, Y (NO 3 ) 3 ·6H 2 0. 2.8730g, 164.973g of powder in total; Add all the above powders into a beaker, add deionized water to mix and stir for 30 minutes, until all nitrates are dissolved, and add citric acid with a nitrate molar ratio of 3:1;

[0076] 2. Stir the prepared solution at 80° C. for 3 hours with a constant temperature magnetic stirrer, and gradually add ammonia water to keep the pH value at about 7, so as to obtain a wet gel precursor;

[0077] 3. Put the obtained wet gel precursor into an oven and dry it at 80°C; and obtain the dry gel precursor;

[0078] 4. Add a little alcohol to the dry gel precursor and ignite it, self-propagating combustion into nano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com