Low-purine beer with uric acid reducing effect

A low-purine, uric acid-lowering technology, applied in beer brewing, beer fermentation methods, malt preparation and other directions, can solve the problems of reducing nucleic acid macromolecular substances, ineffective gout alleviation, and reducing purine content, so as to protect the stomach and intestines. Healthy, significant antioxidant and neuroprotective effects, strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

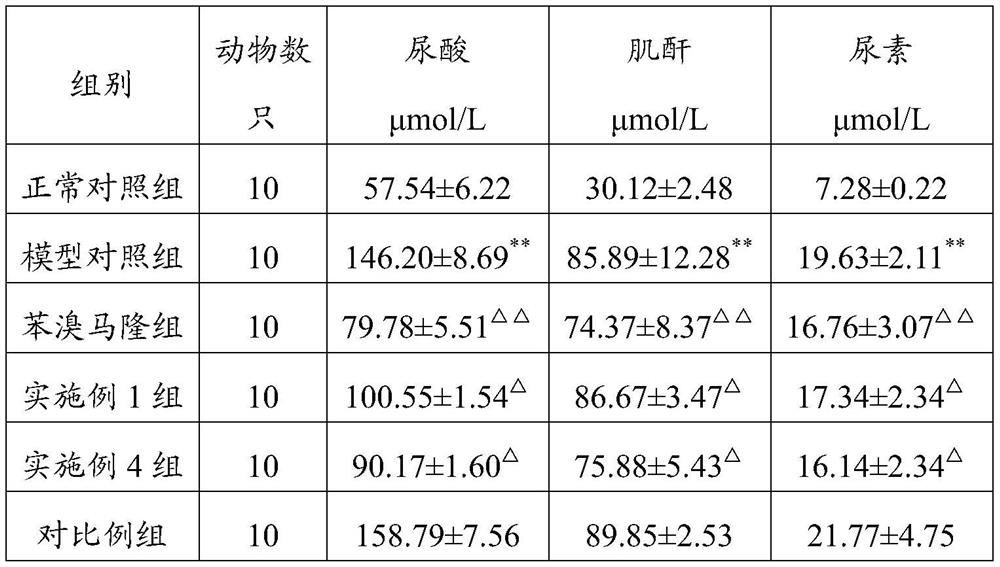

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] Preparation of chitosan oligosaccharide:

[0061] Add 5 parts by mass of chitosan into 100 parts by volume of water and stir evenly, continue to add 3 parts by mass of concentrated hydrochloric acid, accelerate the stirring, and prepare a chitosan solution, adjust the concentration of the chitosan solution with 0.2mol / L acetic acid-sodium acetate buffer solution. The pH is 5, and the chitosan solution temperature is kept at 36°C;

[0062] Add 5 parts by mass of chitosan enzyme to the chitosan solution, stir, hydrolyze for 15 hours to obtain an enzymatic solution, then heat at 90°C for 20 minutes to inactivate the enzyme, centrifuge, take the supernatant, concentrate, and freeze-dry to obtain chitosan oligosaccharides ,spare.

[0063] Dissolving chitosan oligosaccharides in water, followed by dialysis membranes with a molecular cut-off of 2000 and 3000, to finally obtain chitosan oligosaccharides with a molecular weight of 2000-3000 Da, which will be used for later use....

Embodiment 1

[0072] Embodiment 1: the preparation of Dipiaoling beer

[0073] S1 Remove the seed coats and germs of 55 parts by mass of clean barley malt, 25 parts by mass of wheat malt and 5 parts by mass of caramel malt, add water to moisten the malt for 5 minutes, and then pulverize the raw materials;

[0074] S2 After preheating the water in the mash tank to 36°C, put barley malt powder, wheat malt powder, and caramel malt powder into the mash tank, stir evenly, let stand for 15 minutes, and then stir at a speed of 1°C / min Raise the temperature to 52°C, stand still for 55 minutes, raise the temperature to 66°C at a speed of 1°C / min under stirring conditions, stand still for 55 minutes, and raise the temperature to 77°C at a speed of 1°C / min under stirring conditions;

[0075] S3 performing the first filtration on the saccharified mash to obtain clear wort;

[0076] S4 heat the wort to boil, add 0.00020 parts by mass of bitter hops, add 0.00015 parts by mass of aroma hops after 42 minu...

Embodiment 2

[0081] Embodiment 2: the preparation of Dipiaoling beer

[0082] S1 Remove the seed coats and germs of 60 parts by mass of clean barley malt, 40 parts by mass of wheat malt and 10 parts by mass of caramel malt, add water to moisten the malt for 10 minutes, and then pulverize the raw materials;

[0083] S2 Preheat the water in the mash tank to 38°C, put barley malt powder, wheat malt powder, and caramel malt powder into the mash tank, stir evenly, let stand for 20 minutes, and then stir at a speed of 1°C / min Raise the temperature to 53°C, stand still for 60 minutes, raise the temperature to 67°C at a speed of 1°C / min under stirring conditions, stand still for 60 minutes, and raise the temperature to 78°C at a speed of 1°C / min under stirring conditions;

[0084] S3 performing the first filtration on the saccharified mash to obtain clear wort;

[0085] S4 heat the wort to boil, add 0.00025 parts by mass of bitter hops, add 0.00018 parts by mass of aroma hops after 45 minutes, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com