Phosphorus-free polymer corrosion inhibitor composition, phosphorus-free corrosion inhibitor and application of phosphorus-free corrosion inhibitor

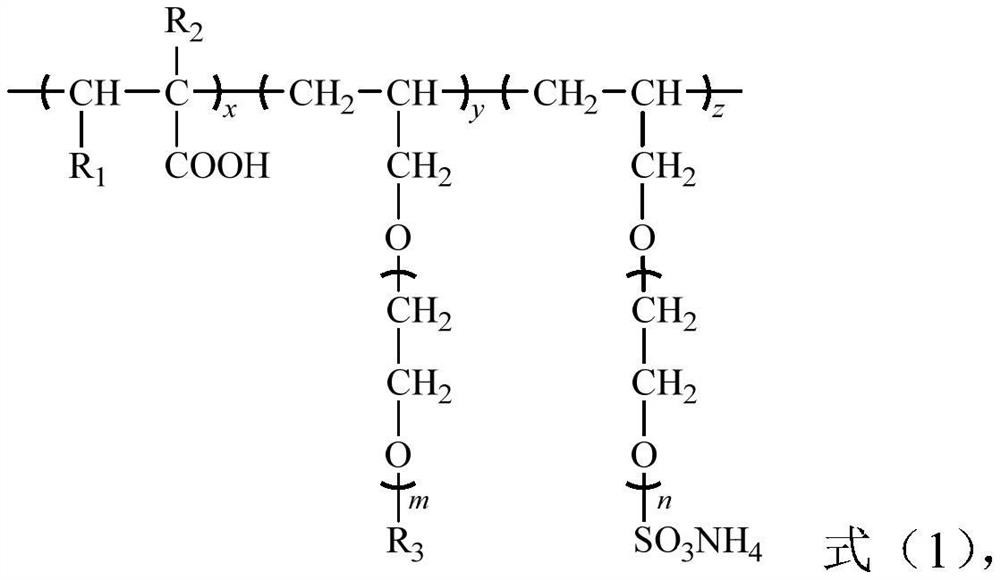

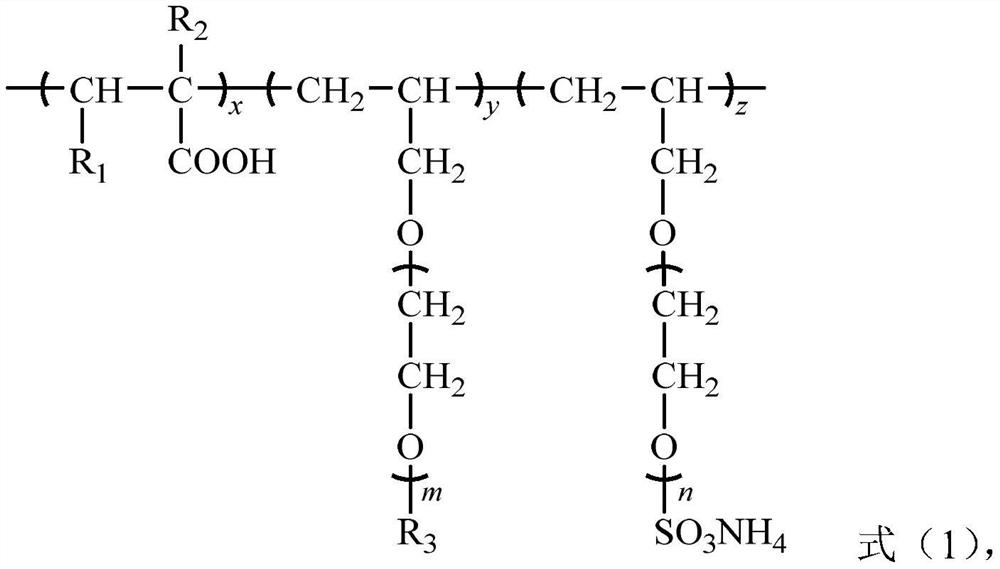

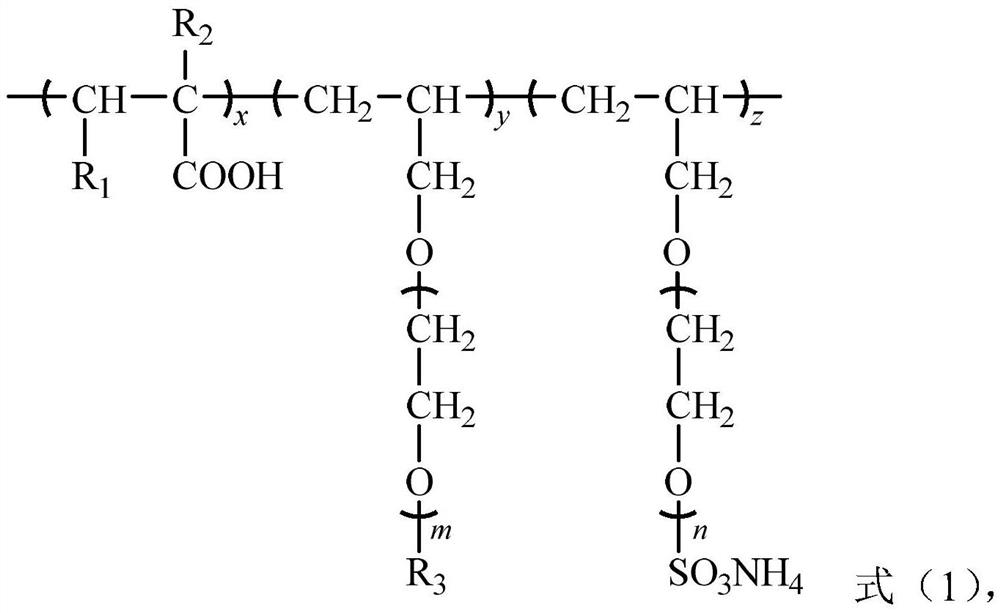

A technology of phosphorus-free corrosion inhibition and composition, which is applied to the application of inhibiting the corrosion of carbon steel in seawater, phosphorus-free polymer corrosion inhibitor composition, and the field of phosphorus-free corrosion inhibitors, which can solve the problem of high cost of corrosion inhibitors and slowing down Large amount of corrosion agent, eutrophication and other problems, to achieve good corrosion inhibition effect, good corrosion inhibition effect and cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0054] Add allyloxypolyethylene glycol (0.1mol) and phthalic acid (0.1mol) with a molecular weight of 498 (that is, m=10) into the reaction kettle for esterification reaction. The reaction temperature is 80°C, and the reaction time is For 3h, generate allyloxy polyethylene glycol phthalate monoester derivatives.

[0055] Add allyloxypolyethylene glycol (0.1mol) and sulfamic acid (0.1mol) with a molecular weight of 498 (n=10) into the reaction kettle, and react at 110°C for 3 hours to generate allyloxypolyethylene glycol. Glycol sulfonate.

[0056] Three polymerized monomers—maleic anhydride (1.0 g), allyloxypolyethylene glycol phthalate monoester derivatives (3.0 g), allyloxy polyethylene glycol sulfonate (3.0 g), and distilled water (20.0g) was added in the reaction kettle, stirred evenly, and 2g of sodium persulfate solution with a mass fraction of 20% was added dropwise at 60°C, and the dropping time was 1h, and the temperature was raised to 80°C after the addition was com...

preparation example 2

[0058] Add allyloxypolyethylene glycol (0.1 mol) and maleic anhydride (0.1 mol) with a molecular weight of 498 (ie m=10) into the reactor to carry out esterification reaction. The reaction temperature is 80°C and the reaction time is 3h, generate allyloxy polyethylene glycol maleate monoester derivatives.

[0059] Add allyloxypolyethylene glycol (0.01mol) and sulfamic acid (0.01mol) with a molecular weight of 2480 (n=55) into the reactor, and react at 120°C for 4 hours to generate allyloxypolyethylene glycol. Glycol sulfonate.

[0060]Three polymerized monomers—methacrylic acid (1.0g), allyloxy polyethylene glycol maleate monoester derivatives (3.0g), allyloxy polyethylene glycol sulfonate (3.0g ), and distilled water (20.0g) were added to the reaction kettle, stirred evenly, and 2g of ammonium persulfate solution with a mass fraction of 20% was added dropwise at 65°C, and the dropping time was 1h. 4h, cooled to room temperature, the obtained brown solution is the compound A...

preparation example 3

[0062] Add allyloxypolyethylene glycol (0.1 mol) and maleic anhydride (0.1 mol) with a molecular weight of 498 (ie m=10) into the reactor to carry out esterification reaction. The reaction temperature is 80°C and the reaction time is 3h, generate allyloxy polyethylene glycol maleate monoester derivatives.

[0063] Add allyloxypolyethylene glycol (0.01mol) and sulfamic acid (0.01mol) with a molecular weight of 2480 (n=55) into the reactor, and react at 120°C for 4 hours to generate allyloxypolyethylene glycol. Glycol sulfonate.

[0064] Three kinds of polymerized monomers—maleic anhydride (4.0g), allyloxy polyethylene glycol maleic acid monoester derivatives (2.5g), allyloxy polyethylene glycol sulfonate (0.5g ), and distilled water (20.0g) were added to the reaction kettle, stirred evenly, and 2g of ammonium persulfate solution with a mass fraction of 20% was added dropwise at 65°C, and the dropping time was 1h. 3h, cooled to room temperature, the resulting brown solution is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com