Composite metal oxide, raw material composition and preparation method and application thereof

A raw material composition and composite metal technology, applied in the preparation of organic compounds, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve separation difficulties, and copper-based catalysts are easy to agglomerate and deactivate Wait for the question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~12 and comparative example 1~6

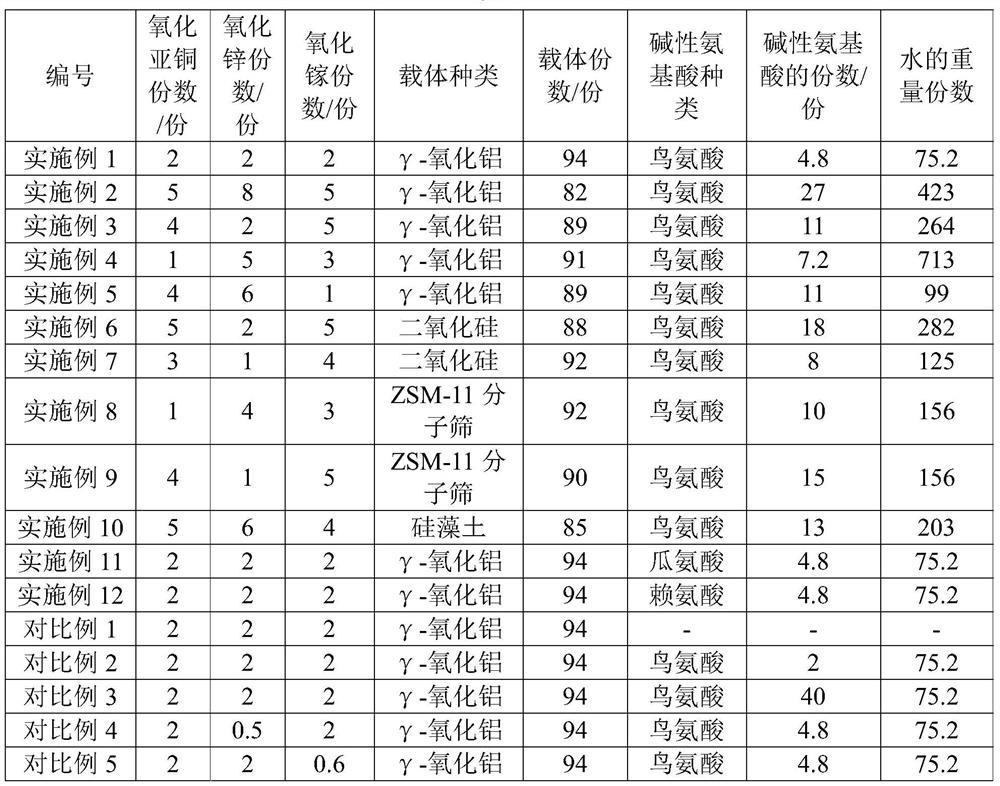

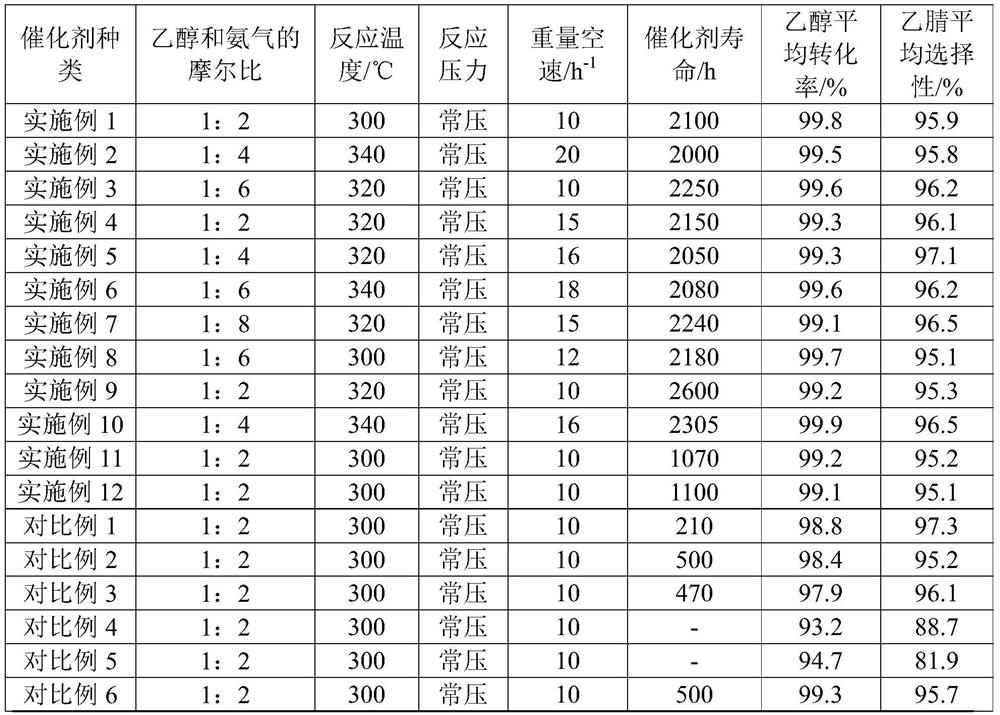

[0072] The raw material compositions of composite metal oxides in the examples and comparative examples are shown in Table 1, and the preparation method specifically includes the following steps:

[0073] (1) Mix cuprous oxide, zinc oxide, gallium oxide, basic amino acid and water, adjust the pH of the system to 10 with hydrochloric acid with a concentration of 0.1mol / L, that is, adjust to the isoelectric point of the basic amino acid, and obtain Amino acid trimetal complexes;

[0074] (2) Grinding the carrier, the mesh of which is 80 mesh, is ready for use; add the ground carrier to the amino acid trimetallic complex prepared in step (1), immerse at room temperature for 24 hours, and heat to 50° C. , and then carry out crystallization, the crystallization time is 24h, filter and collect the filter residue, wash the filter residue 3 to 5 times with distilled water, dry at 110°C for 6h, and finally calcinate at 520°C for 4h to obtain a composite metal oxide.

[0075] In the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com