with silica and tcl 4 Method for preparing highly active propylene and hydrogen peroxide gas-phase epoxidation catalyst by gas-solid phase reaction

A technology of oxidation catalyst and white carbon black, which is applied in the direction of physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of reducing the catalytic activity of the catalyst, reducing the reliability of the catalyst, and affecting the diffusion performance of the catalyst.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0091] The first step is to dry and pre-calcine the white carbon black raw material.

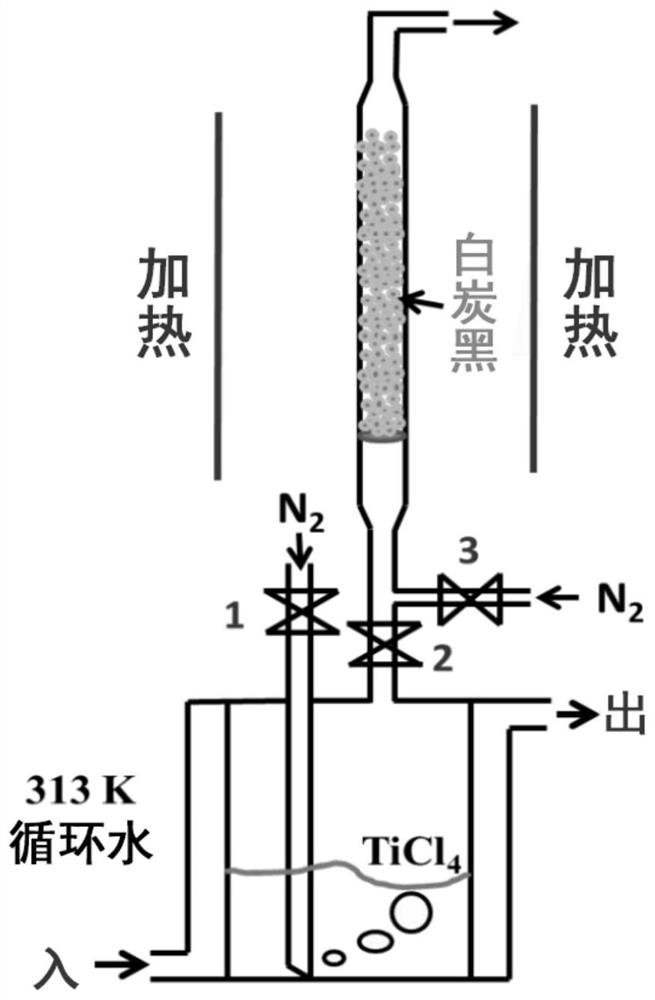

[0092] In this example, a commercially available fumed silica is used as the raw material, and its main specifications are characterized by a specific surface area of 380m 2 / g. In order to facilitate the drying and roasting pretreatment under the flowing atmosphere in the laboratory, the silica was first pressed into tablets and sieved, and the silica with a particle size of 20-40 mesh was selected as the experimental sample. The drying and roasting pretreatment of the experimental samples were carried out in situ on the gas-solid phase grafting reaction device. A schematic diagram of the reaction apparatus is attached figure 1 .

[0093] Add 6g of white carbon black with a particle size of 20-60 mesh into the reaction tube of the reaction device. Then, the silica was subjected to drying pretreatment in a nitrogen flow (60 ml / min), the drying temperature was 110° C., and the drying ti...

Embodiment 2

[0116] Repeat embodiment 1, but in the hydrothermal crystallization treatment stage of the 3rd step, the consumption of tetrapropyl ammonium hydroxide is mold silicon ratio (TPA + / SiO 2 ) by changing the template solution concentration to 0.03, 0.039, 0.048 respectively, keeping the water-to-silicon ratio unchanged, and prolonging the hydrothermal crystallization time to 72 hours. It corresponds to the mold-to-silicon ratio (TPA + / SiO 2 ) were 0.03, 0.039 and 0.048 in sequence, and the gas phase epoxidation reaction results of propylene in the sample were: the conversion rate of propylene was 6.3%, 11.8% and 15.2% in sequence, and the effective utilization rate of hydrogen peroxide was 27.6%, 50.7% and 67.8% in sequence .

[0117] This example illustrates that the die-to-silicon ratio (TPA + / SiO 2 ) is the influence of silica TiCl 4 important factor in the outcome of hydrothermal crystallization of grafts. But adopt catalyst preparation method provided by the inventi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com