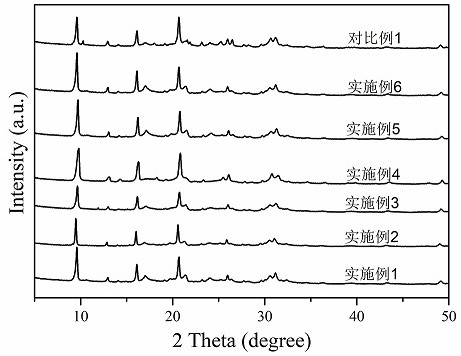

A kind of preparation method of multi-stage porous sapo-34 molecular sieve

A molecular sieve and multi-stage pore technology, which is applied in the direction of molecular sieve catalyst, molecular sieve characteristic silicoaluminophosphate, molecular sieve and alkali-exchanged phosphate, etc., can solve the problems of expensive organic templates, inability to realize industrialization, increase synthesis cost and environmental pollution, and achieve The effect of increasing lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

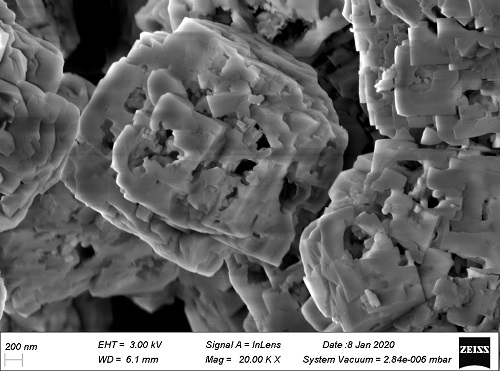

Embodiment 1

[0049] Preparation of aluminum phosphate balls: Add 0.1mol / L newly prepared aluminum phosphate solution and 0.1mol / L phosphoric acid solution into a beaker, stir and mix evenly, transfer to a hydrothermal kettle for 3 hours of hydrothermal treatment at 90°C, take out and cool; high-speed centrifugation and washed three times with water, and dried at 100°C to obtain spherical aluminum phosphate powder. The product is nearly spherical in shape with an average particle size of 100nm.

[0050] Mix and grind aluminum phosphate balls and white carbon black in a mortar for 20 minutes to obtain a precursor dry powder; place the obtained precursor dry powder in a polytetrafluoro cup on the upper part of the crystallization kettle, and the polytetrafluoro cup is supported by a bracket. Place deionized water and triethylamine at the bottom; the molar ratio of each component in the reactor is 1.5 triethylamine: 17H 2 O: 0.5SiO 2 : 1Al 2 o 3 : 1P 2 o 5 . Seal the crystallization ket...

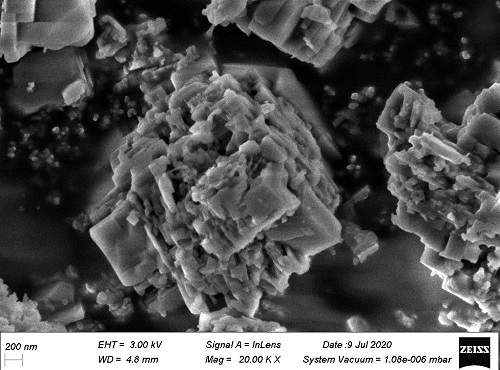

Embodiment 2

[0053] Preparation of aluminum phosphate balls: Add 0.1mol / L newly prepared aluminum phosphate solution and 0.1mol / L phosphoric acid solution into a beaker, stir and mix evenly, transfer to a hydrothermal kettle for 3 hours of hydrothermal treatment at 90°C, take out and cool; high-speed centrifugation and washed three times with water, and dried at 100°C to obtain spherical aluminum phosphate powder. The product is nearly spherical in shape with an average particle size of 100nm.

[0054] Mix and grind aluminum phosphate balls and silica sol in a mortar for 20 minutes to obtain a precursor, dry it in an oven, and grind it into a powder after the water evaporates completely to obtain a dry powder of a molecular sieve precursor; In the polytetrafluoro cup on the upper part of the crystallization kettle, the polytetrafluoro cup is supported by a bracket, and deionized water and morpholine are placed at the bottom of the kettle; the molar ratio of each component in the reaction k...

Embodiment 3

[0057] Preparation of aluminum phosphate balls: Add 0.2mol / L newly prepared aluminum phosphate solution and 0.2mol / L phosphoric acid solution into a beaker, stir and mix evenly, transfer to a hydrothermal kettle for 2 hours of hydrothermal treatment at 100°C, take out and cool; high-speed centrifugation and washed three times with water, and dried at 100°C to obtain spherical aluminum phosphate powder. The product has a nearly spherical shape with an average particle size of 200nm.

[0058] Mix and grind aluminum phosphate balls, tetraethyl orthosilicate and triethanolamine in a mortar for 10 minutes to obtain dry precursor powder; place the dry precursor powder in the polytetrafluoro cup on the upper part of the crystallization kettle Supported by a bracket, deionized water is placed at the bottom of the kettle; the molar ratio of each component in the reactor is 3 triethanolamine: 20H 2 O: 0.6SiO 2 : 1Al 2 o 3 : 1P 2 o 5 . Seal the crystallization kettle and place it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com