Large-area flexible thermoelectric refrigeration film cascade device and preparation method thereof

A technology of thermoelectric refrigeration and thermoelectric thin film, which is applied in the manufacture/processing of thermoelectric devices, thermoelectric devices, thermoelectric device junction lead-out materials, etc., and can solve problems affecting the structural accuracy of devices, deterioration of cooling performance, and widening of film edges. Achieve the effects of improving electrical transport performance, improving refrigeration performance, and reducing device internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

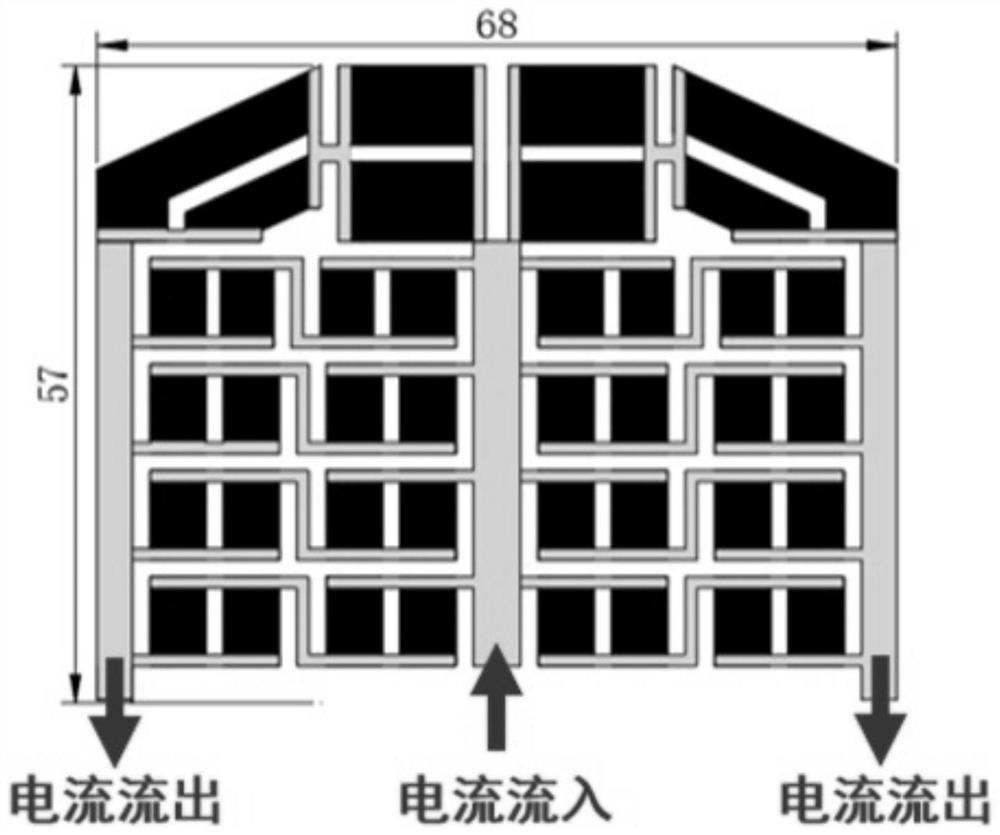

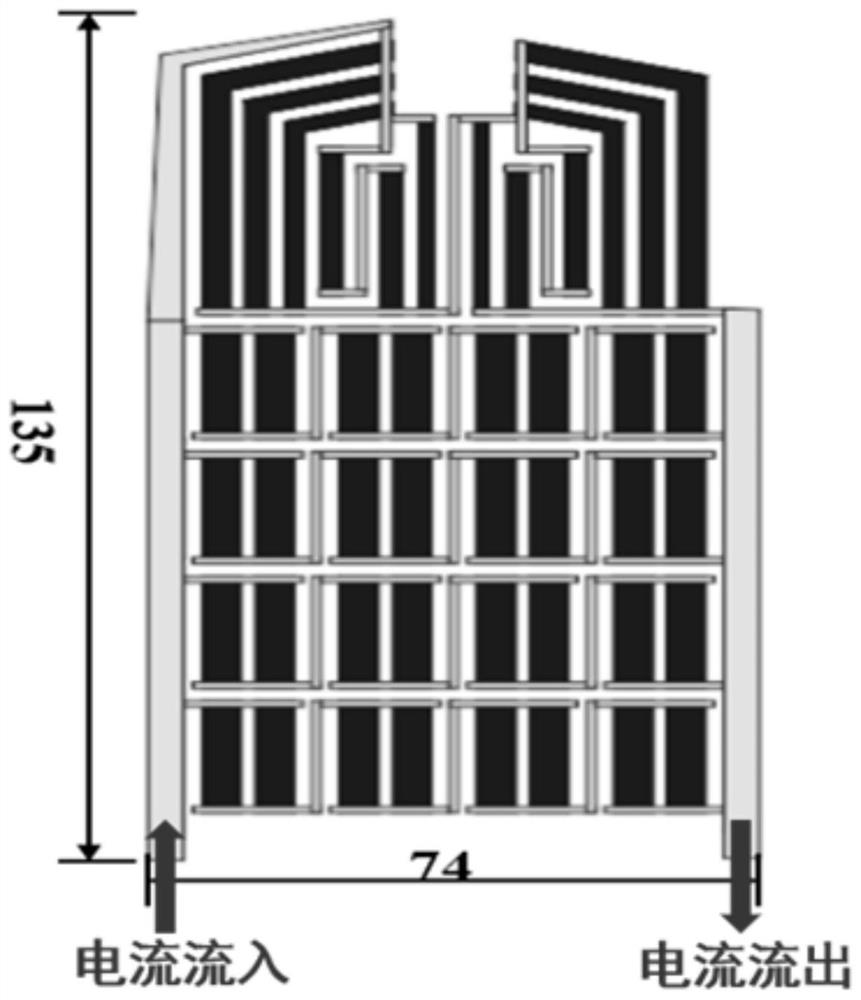

[0030] The structure of the large-area flexible thermoelectric refrigeration film five-stage cascaded device prepared in this example is as follows: figure 1 As shown (the black area is the thermoelectric arm, the gray area is the electrode), the overall size of the device is 68×57mm 2 , the first level is the cooling area, and the remaining four levels are cooling areas. The preparation method of the device is as follows:

[0031] p-type Bi 0.5 Sb 1.5 Te 3 The ingot is smashed, ground, and passed through a 120-mesh sieve to obtain a ready-to-use powder with a particle size of less than 120 μm;

[0032] According to the calculated mass percentage, weigh the above Bi 0.5 Sb 1.5 Te 3 Add 9.9g of powder and 0.1g of graphene to a high-energy ball mill tank (ball-to-material ratio 55:1) and then add 50mL of absolute ethanol as the ball milling medium. After sealing, vacuumize and flush into Ar gas protection to start ball milling. Ball milling process parameters: ball milli...

Embodiment 2

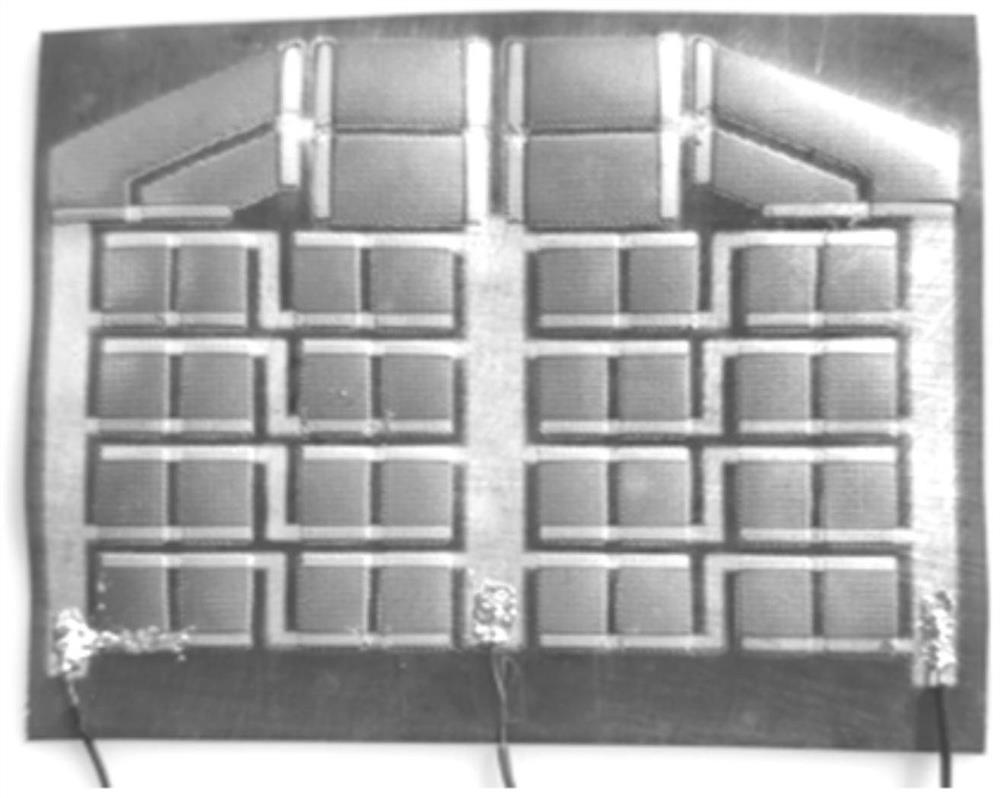

[0040] The structural schematic diagram and physical photos of the large-area flexible thermoelectric cooling film five-stage cascaded device prepared in this example are as follows Figure 1-2 As shown, the device preparation method is as follows:

[0041] p-type Bi 0.5 Sb 1.5 Te 3 The ingot is smashed, ground, and passed through a 120-mesh sieve to obtain a ready-to-use powder with a particle size of less than 120 μm;

[0042] According to the calculated mass percentage, weigh the above Bi 0.5 Sb 1.5 Te 3 Add 9.9g of powder and 0.1g of graphene to a high-energy ball mill tank (ball-to-material ratio 55:1) and then add 50mL of absolute ethanol as the ball milling medium. After sealing, vacuumize and flush into Ar gas protection to start ball milling. Ball milling process parameters: ball milling speed 200r / min, ball milling 2h;

[0043] The ball-milled powder was centrifuged at a speed of 4000r / min for 10 minutes, the lower layer of slurry was removed and placed in a v...

Embodiment 3

[0050] The structure of the large-area flexible thermoelectric refrigeration film five-stage cascaded device prepared in this example is as follows: figure 1 Shown, concrete preparation method is as follows:

[0051] p-type Bi 0.5 Sb 1.5 Te 3 The ingot is smashed, ground, and passed through a 120-mesh sieve to obtain a ready-to-use powder with a particle size of less than 120 μm;

[0052] According to the calculated mass percentage, weigh the above Bi 0.5 Sb 1.5 Te 3 Add 9.9g of powder and 0.1g of graphene to a high-energy ball mill tank (ball-to-material ratio 55:1) and then add 50mL of absolute ethanol as the ball milling medium. After sealing, vacuumize and flush into Ar gas protection to start ball milling. Ball milling process parameters: ball milling speed 200r / min, ball milling 2h;

[0053] The ball-milled powder was centrifuged at a speed of 4000r / min for 10min, the lower layer of slurry was removed and placed in a vacuum drying oven, heated to 60°C and vacuum-d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com