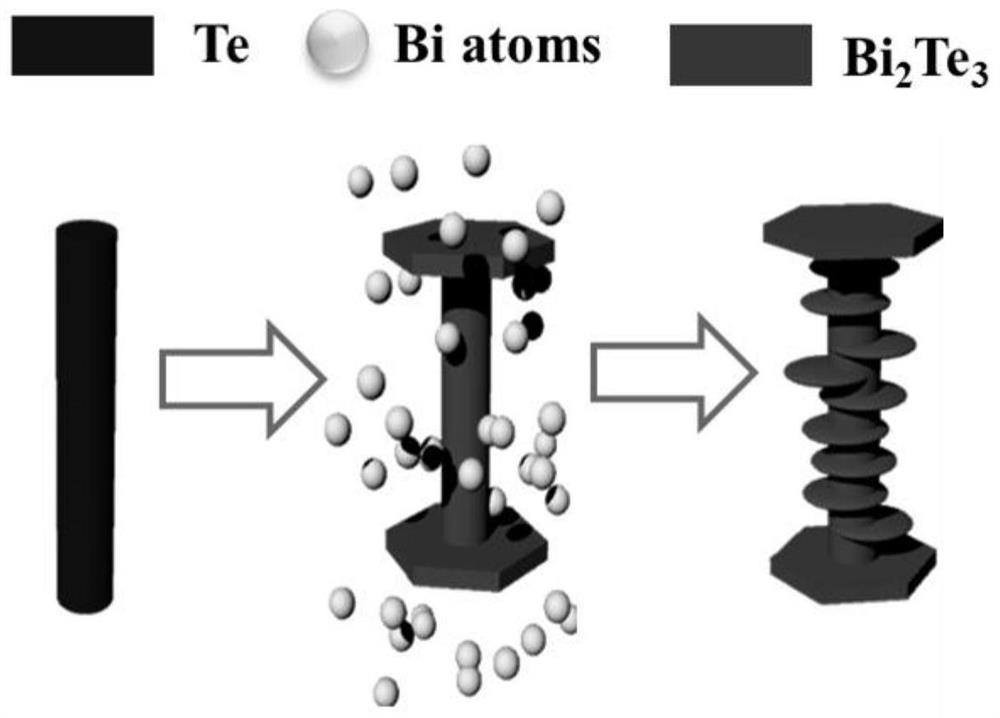

Bismuth telluride nanowire with zigzag structure and preparation method of bismuth telluride nanowire

A bismuth telluride nanometer and zigzag technology, applied in chemical instruments and methods, selenium/tellurium compounds, metal selenides/tellurides, etc., can solve problems such as energy efficiency that is difficult to meet commercial applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

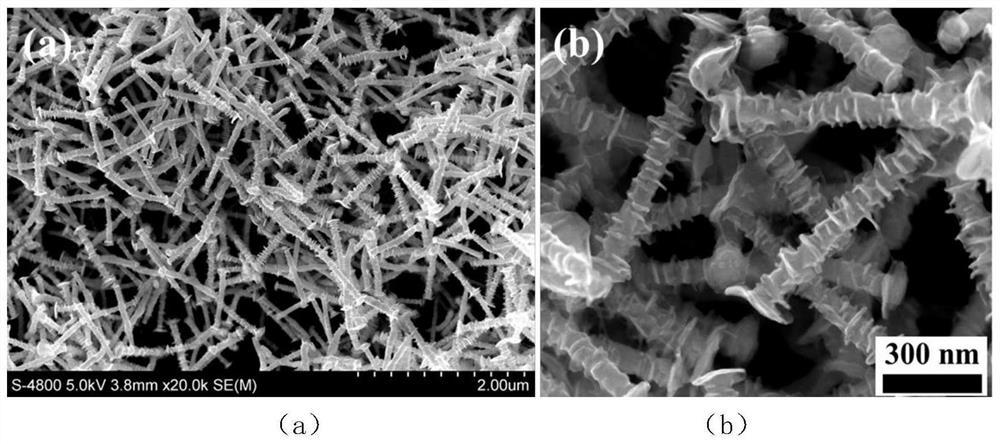

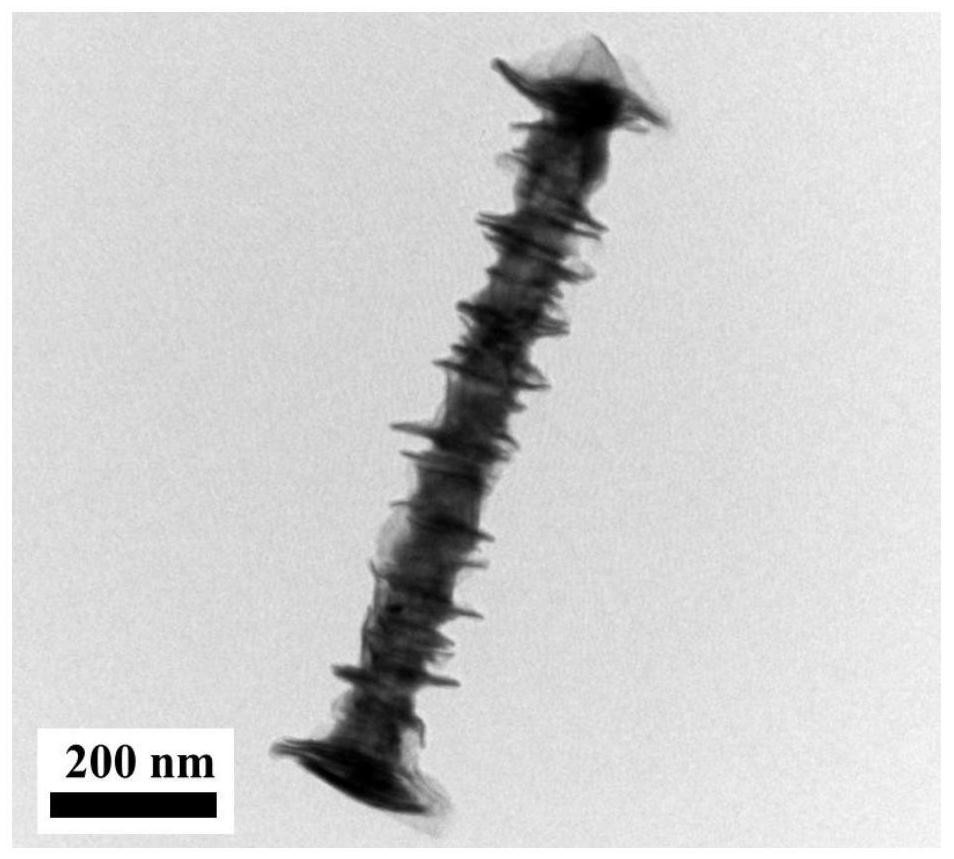

[0040] Step 1, the TeO of 0.1596g (1mmol) 2, 0.5g PVP and 3.74g (8mmol) KOH, mixed and dissolved in 20ml EG at room temperature, fully dissolved into a transparent liquid by magnetic stirring; then poured into a 100ml three-necked bottle, under nitrogen protection, circulating water cooling and Under the condition of magnetic stirring, heat the mixed solution to 160°C, quickly inject 3ml of hydrazine hydrate, keep it warm for 1 hour, then lower the temperature to 120°C for use;

[0041] Step 2, 0.310g (0.33mmol) bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 O) The particles are mixed with 5ml of ethylene glycol, and the mixed solution is heated to 120° C. under magnetic stirring. When the solution is colorless and transparent, the Bi precursor solution at 120° C. is hot-injected into the Te nanowire solution with a syringe. Subsequently, 3 ml of concentrated hydrochloric acid with a concentration of 35% was injected into the mixed solution, kept for 2 hours, and then natu...

Embodiment 2

[0046] Step 1, the TeO of 0.2394g (1.5mmol) 2 , 0.75g PVP and 5.6g (10mmol) KOH, mixed and dissolved in 30ml EG at room temperature, fully dissolved into a transparent liquid by magnetic stirring; then poured into a 100ml three-necked bottle, under nitrogen protection, circulating water cooling and Under the condition of magnetic stirring, heat the mixed solution to 160°C, quickly inject 4.5ml of hydrazine hydrate, keep it warm for 1 hour, then lower the temperature to 120°C for use;

[0047] Step 2, at the same time, bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 O) The particles are mixed with 5ml of ethylene glycol, and the mixed solution is heated to 120° C. under magnetic stirring. When the solution is colorless and transparent, the Bi precursor solution at 120° C. is hot-injected into the Te nanowire solution with a syringe. Inject 4.5ml of concentrated hydrochloric acid with a concentration of 35% into the mixed solution subsequently, and naturally cool to room temp...

Embodiment 3

[0051] Step 1, the TeO of 0.4788g (3mmol) 2 , 1.5g PVP and 11.2g (20mmol) KOH, mixed and dissolved in 60ml EG at room temperature, fully dissolved into a transparent liquid by magnetic stirring; then poured into a 200ml three-necked bottle, under nitrogen protection, circulating water cooling and Under the condition of magnetic stirring, heat the mixed solution to 160°C, quickly inject 8ml of hydrazine hydrate, keep it warm for 1 hour, then lower the temperature to 120°C for use;

[0052] Step 2, at the same time, bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 O) The particles are mixed with 10ml of ethylene glycol, and the mixed solution is heated to 120° C. under magnetic stirring. When the solution is colorless and transparent, the Bi precursor solution at 120° C. is hot-injected into the Te nanowire solution with a syringe. Inject 8ml concentration into the mixed solution subsequently and be the concentrated hydrochloric acid of 35%, naturally cool to room temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com