Method for preparing alkynyl polyether modified organic silicon surfactant by adopting copper carbene catalyst

A surfactant and carbene catalyst technology, which is applied in the field of polyether-based modified silicone, can solve the problem of unsatisfactory activity of modified silicone, and achieve excellent physical properties, convenient operation, and high activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

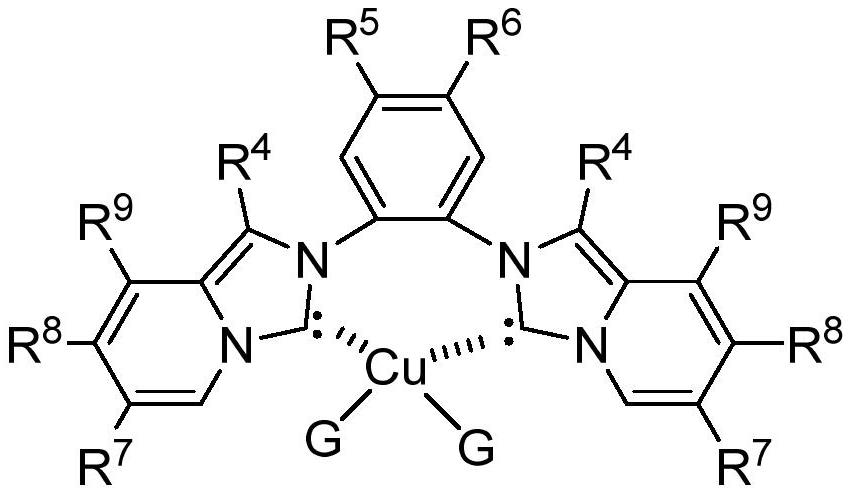

[0025]Example 1 Preparation of copper carbene catalyst:

[0026]The preparation method of the copper carbene catalyst used in the present invention refers to the literature: ORGANIC LETTERS2011Vol.13, No.195256-5259; Journal of Organometallic Chemistry 775(2015)155-163; Journal of Organometallic Chemistry 820(2016)1-7; Journal of Catalysis 319 (2014) 119-126; Tetrahedron: Asymmetry 24 (2013) 492-498.

[0027]

[0028]The specific preparation method takes the above structure as an example, and the steps are as follows:

[0029](1)

[0030]

[0031]In a 500 ml reaction vessel, add 23 g (5-isopropyl-2-pyridyl) phenyl ketone, 200 ml methanol, and 5.4 g o-phenylenediamine in sequence. Under the condition of sufficient stirring, add hydrochloric acid gas to The solution was saturated, reacted at room temperature for 5 hours, and then filtered. The filter cake was washed three times with 20 ml of methanol to obtain 28 g of bisimidazole salt with a yield of 90%.

[0032](2)

[0033]

[0034]Disperse 6.2 g of the bisi...

Embodiment 2

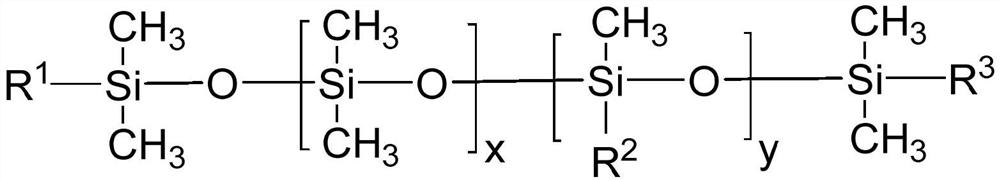

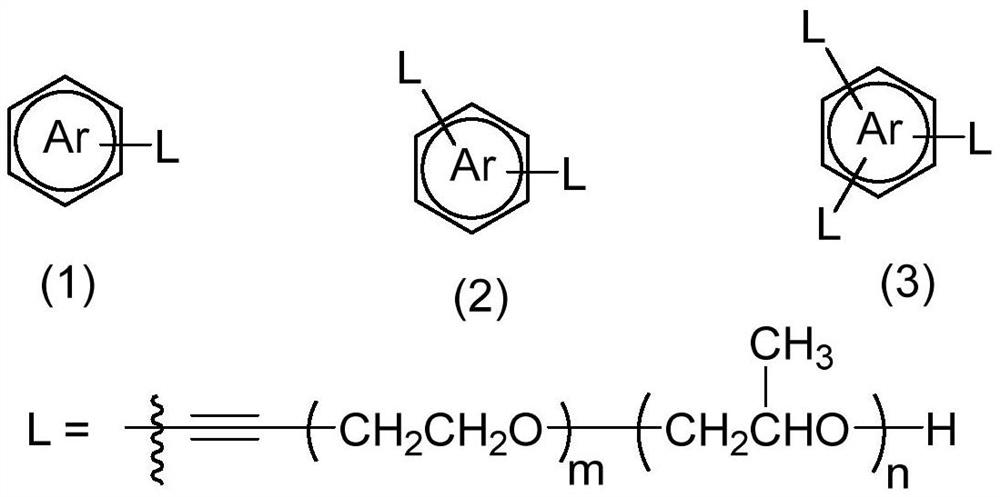

[0036]Synthesize an alkynyl polyether-modified organosilicon surfactant with alkynyl polyether derived from phenylacetylene as raw material (200≥m≥0, 200≥n≥0):

[0037]

[0038]In a 250L reactor with a fixed device, constant temperature function, mechanical stirring, thermocouple and nitrogen gas, 100kg of alkynyl polyether with an average molecular weight of 850 as shown above, and 43kg Hydrogen-containing polysiloxane, start stirring, use a heating mantle to heat to 60°C, stir for 5 minutes, add 1kg of catalyst, and react for 4 hours to obtain a clear and transparent light yellow silicone copolymer liquid. Put the silicone copolymer in a vacuum Under the conditions, a thin film evaporator with vacuum, heating and stirring is pumped in. The temperature of the evaporator is 120°C, the relative vacuum pressure is -0.1MPa, and the vacuum time is 12 hours. Finally, the temperature is slowly reduced to 30°C under vacuum, which is alkyne -Based polyether modified silicone surfactant.

[0039]The ...

Embodiment 3

[0043]Synthesize an alkynyl polyether modified silicone surfactant with alkynyl polyether derived from p-toluene acetylene as a raw material:

[0044]

[0045]In a 250L reactor with a fixed device, constant temperature function, mechanical stirring, thermocouple and nitrogen gas, 105kg of alkynyl polyether with an average molecular weight of 950 as shown above is added, and 43kg as shown above Hydrogen-containing polysiloxane, start stirring, use a heating mantle to heat to 60°C, stir for 5 minutes, add 1.1 kg of catalyst, and react for 4 hours to obtain a clear and transparent light yellow silicone copolymer liquid. A thin film evaporator with vacuum, heating and stirring is pumped in under vacuum. The temperature of the evaporator is 120°C, the relative vacuum pressure is -0.1MPa, and the vacuum time is 12 hours. Finally, the temperature is slowly reduced to 30°C under vacuum. Alkynyl polyether modified silicone surfactant.

[0046]The synthesis method of the above-mentioned alkynyl polyet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com