A modified high blood-sucking polyurethane sponge, preparation method and use thereof

A polyurethane sponge, modified technology, applied in the direction of absorbent pads, bandages, medical science, etc., can solve the problems of increased biological toxicity, poor absorption performance, and decreased mechanical properties, so as to reduce the reduction of absorption capacity and improve blood absorption capacity , the effect of increasing biosecurity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

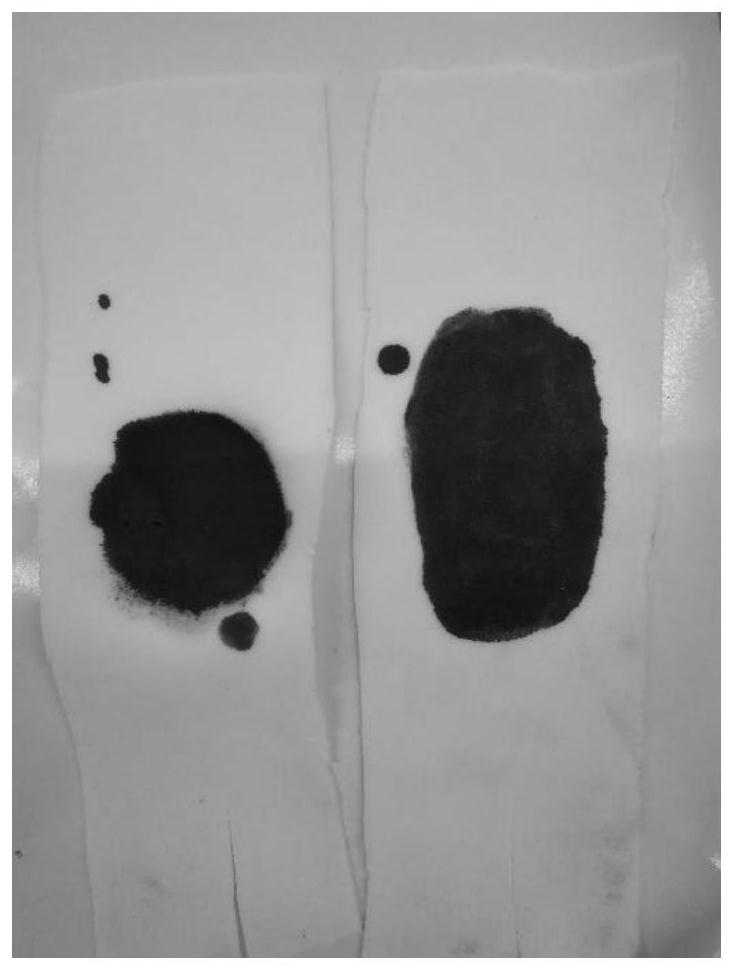

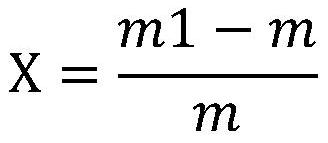

Image

Examples

Embodiment 1

[0079] A, take by weight respectively: a kind of modified high blood-sucking polyurethane sponge is made by the raw material that comprises following weight portion: 30 parts of isocyanates, wherein the mass ratio of methyl isocyanate and hexamethylene isocyanate is 6:4 , 18 parts of polylactic acid glycol, 42 parts of PEG-2000, 15 parts of fluff pulp, 30 parts of super absorbent WHS 300, 5 parts of chitosan, 90 parts of water, hydrophilic surfactant ( PE6400: 188=1:2) 5 parts, chain extender TMP 2 parts, inorganic filler 300 mesh diatomaceous earth 20 parts, antioxidant IRGASTAB PUR 68 0.3 parts;

[0080] B. Place isocyanate, polyether polyol, polyester polyol, polymer polyol, chain extender, and antioxidant at 80°C for 12 hours to react to obtain a polyol modified prepolymer;

[0081] C. Mix the fluff pulp fiber, chitosan, hydrophilic surfactant, inorganic filler with water to obtain white material, and keep it at 20±2℃;

[0082] D. Heat the prepolymer to 40°C, then mix ...

Embodiment 2

[0086] A, take by weighing respectively by weight: a kind of modified high blood-sucking polyurethane sponge is made by the raw material that comprises following weight portion: 30 parts of isocyanates, wherein the ratio of methyl isocyanate and hexamethylene isocyanate is 6:4, 36 parts of polylactic acid glycol, 84 parts of PEG-2000, 15 parts of fluff pulp, 30 parts of superabsorbent WHS 300, 5 parts of chitosan, 90 parts of water, hydrophilic surfactant ( PE6400: 188=1:2) 5 parts, chain extender TMP 2 parts, inorganic filler 300 mesh diatomaceous earth 20 parts, antioxidant IRGASTAB PUR 68 0.3 parts;

[0087] B. Place isocyanate, polyether polyol, polyester polyol, polymer polyol, chain extender, and antioxidant at 80°C for 12 hours to react to obtain a polyol modified prepolymer;

[0088] C. Mix the fluff pulp fiber, chitosan, hydrophilic surfactant, inorganic filler with water to obtain white material, and keep it at 20±2℃;

[0089] D. Heat the prepolymer to 40°C, then...

Embodiment 3

[0093] A, take by weighing respectively by weight: a kind of modified high blood-sucking polyurethane sponge is made by the raw material that comprises following weight portion: 30 parts of isocyanates, wherein the ratio of methyl isocyanate and hexamethylene isocyanate is 6:4, 30 parts of polylactic acid glycol, 70 parts of PEG-2000, 15 parts of fluff pulp, 30 parts of superabsorbent WHS 300, 15 parts of chitosan, 90 parts of water, hydrophilic surfactant ( PE6400: 188=1:2) 5 parts, chain extender TMP 2 parts, inorganic filler 300 mesh diatomaceous earth 20 parts, antioxidant IRGASTAB PUR 68 0.3 parts;

[0094] B. Place isocyanate, polyether polyol, polyester polyol, polymer polyol, chain extender, and antioxidant at 80°C for 12 hours to react to obtain a polyol modified prepolymer;

[0095] C. Mix the fluff pulp fiber, chitosan, hydrophilic surfactant, inorganic filler with water to obtain white material, and keep it at 20±2℃;

[0096] D. Heat the prepolymer to 40°C, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com