Rare earth modified aluminum-based adsorbent as well as preparation method and application thereof

A rare earth modification and adsorbent technology, applied in chemical instruments and methods, other chemical processes, photographic processes, etc., can solve the problems of complex composition of electrolytic zinc solution, need to improve adsorption efficiency, insufficient adsorption performance, etc., saving time and energy The effect of operating environment, fast adsorption rate and shortened time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The steps of the preparation method of the rare earth modified aluminum-based adsorbent provided by the present invention are as follows:

[0032] S1, the La(NO 3 ) 3 ·6H 2 O was added to deionized water and stirred at room temperature to fully dissolve it to obtain La(NO 3 ) 3 aqueous solution;

[0033] S2, the La(NO 3 ) 3 The aqueous solution is placed on a magnetic stirrer, and an appropriate amount of pseudo-boehmite is added under the condition of stirring, and the stirring is continued for a period of time, so that the pseudo-boehmite and La(NO 3 ) 3 Fully contact and ensure that lanthanum is relatively uniformly loaded on the aluminum base to obtain a turbid liquid;

[0034] S3, adding glacial acetic acid dropwise to the turbid liquid until the turbid liquid forms a sol;

[0035]S4, drying the sol to a constant weight, the obtained xerogel is the rare earth modified aluminum-based adsorbent, grinding the xerogel to obtain a powder material, and using the...

Embodiment 1

[0044] The steps of the preparation method of the rare earth modified aluminum-based adsorbent in this embodiment are as follows:

[0045] S1, weigh 1.495gLa(NO 3 ) 3 ·6H 2 O in a beaker, add 25ml deionized water, stir at room temperature to make La(NO 3 ) 3 ·6H 2 O is fully dissolved to obtain La(NO 3 ) 3 aqueous solution;

[0046] S2, the La(NO 3 ) 3 The aqueous solution was placed on a magnetic stirrer, and 6.484 g of pseudo-boehmite was added under stirring conditions, and the stirring was continued for 35 minutes to obtain a turbid liquid;

[0047] S3, adding glacial acetic acid dropwise to the turbid liquid until the turbid liquid forms a sol;

[0048] S4, the sol is placed in an oven, and dried at a temperature of 100° C. to a constant weight, and the obtained xerogel is ground to obtain a powder material, that is, a rare earth modified aluminum-based adsorbent powder.

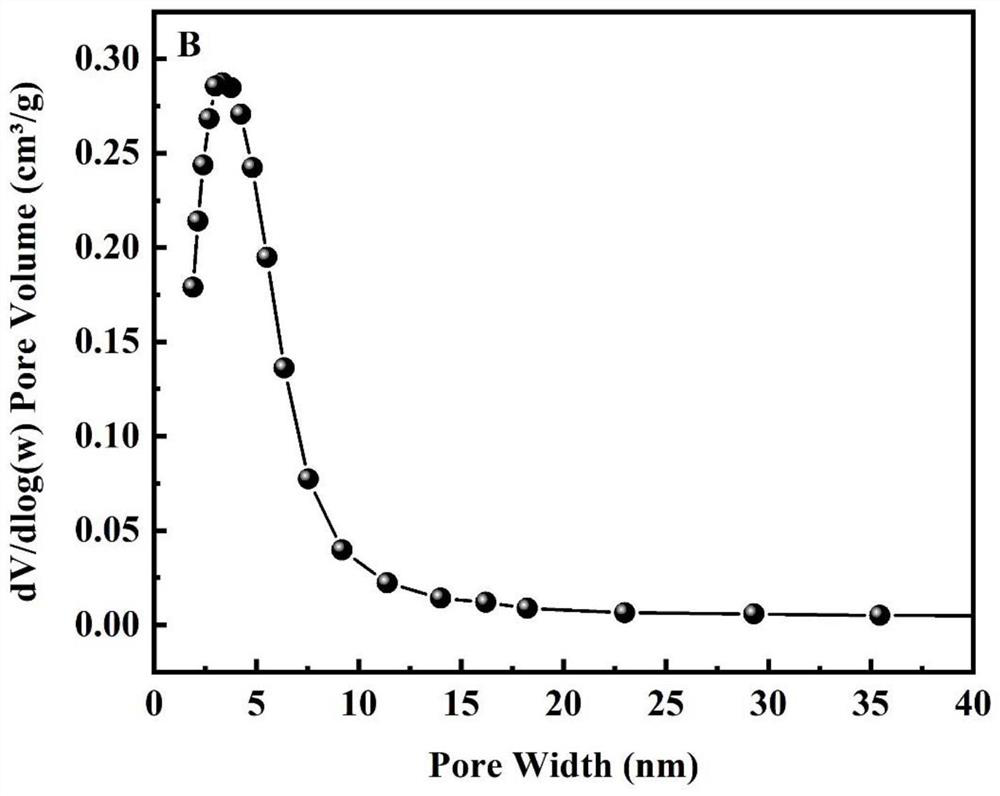

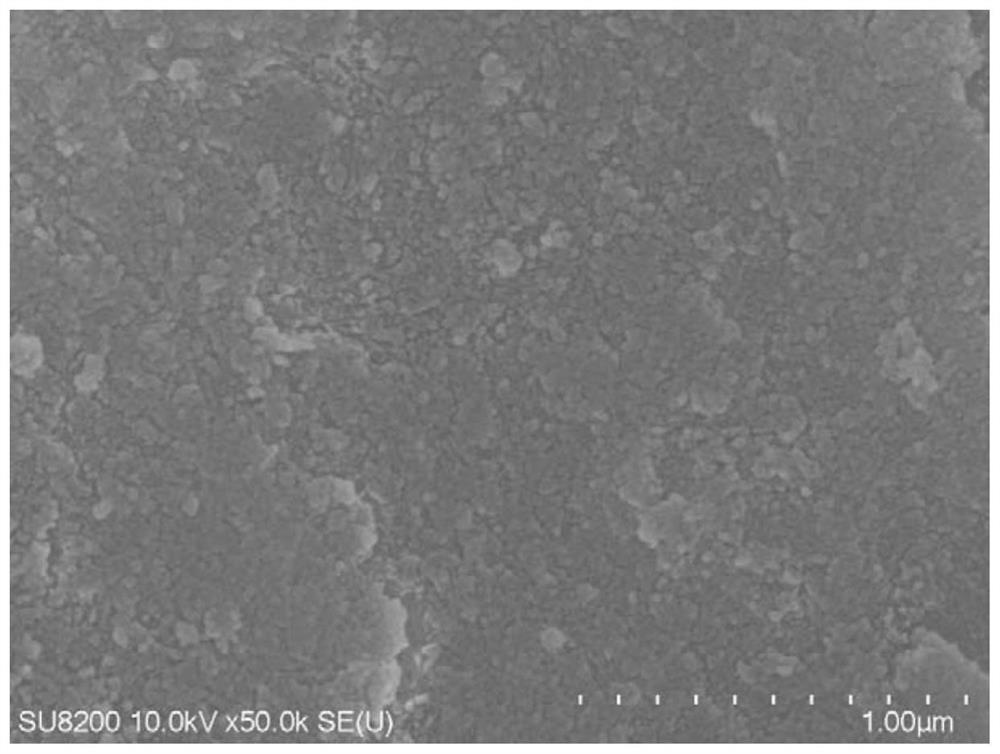

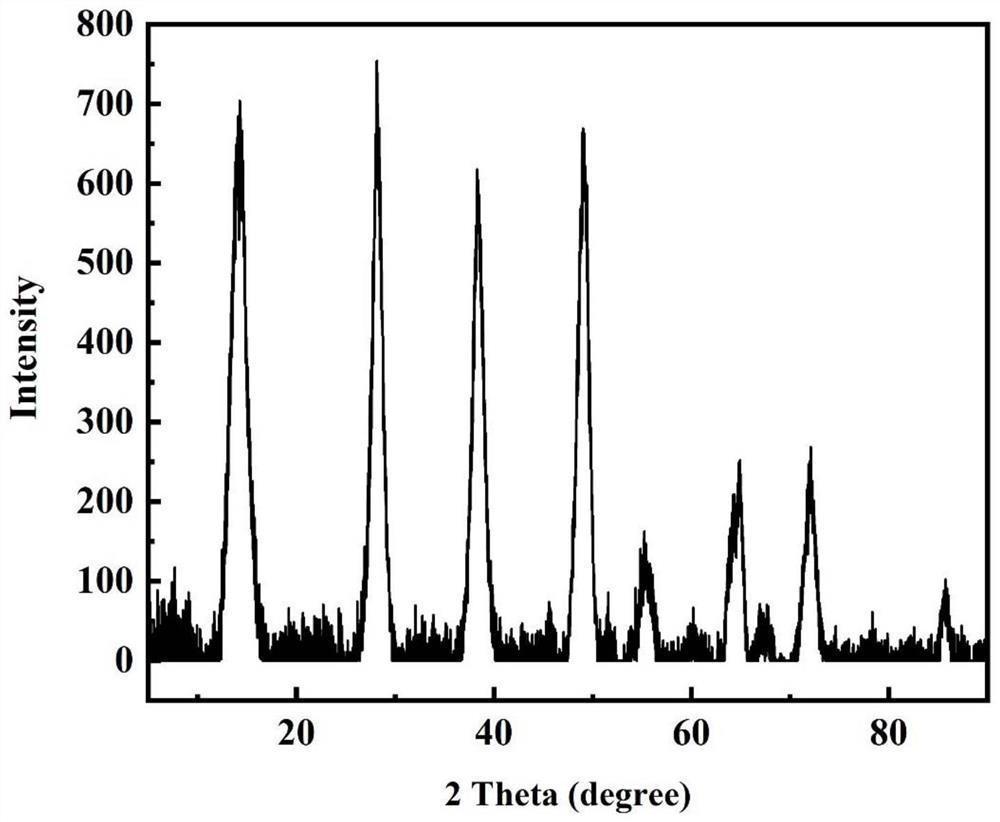

[0049] The specific surface area of the rare earth modified aluminum-based adsorbent ob...

Embodiment 2

[0053] The steps of the preparation method of the rare earth modified aluminum-based adsorbent in this embodiment are as follows:

[0054] S1, weigh 0.595gLa(NO 3 ) 3 ·6H 2 O in a beaker, add 42ml deionized water, stir at room temperature to make La(NO 3 ) 3 ·6H 2 O is fully dissolved to obtain La(NO 3 ) 3 aqueous solution;

[0055] S2, the La(NO 3 ) 3 The aqueous solution was placed on a magnetic stirrer, and 5.355 g of pseudo-boehmite was added under stirring conditions, and the stirring was continued for 20 minutes to obtain a turbid liquid;

[0056] S3, adding glacial acetic acid dropwise to the turbid liquid until the turbid liquid forms a sol;

[0057] S4, the sol is placed in an oven, and dried at a temperature of 160° C. to a constant weight, and the obtained xerogel is ground to obtain a powder material, that is, a rare earth modified aluminum-based adsorbent powder.

[0058] The specific surface area of the rare earth modified aluminum-based adsorbent ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com