Preparation method of high-purity pramipexole dihydrochloride

A high-purity technology for pramipexole hydrochloride, which is applied in the field of preparation of high-purity pramipexole hydrochloride, can solve problems such as low reaction yield, cumbersome process, and loss of crystal water, and achieve simple reaction steps, high safety, water a stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

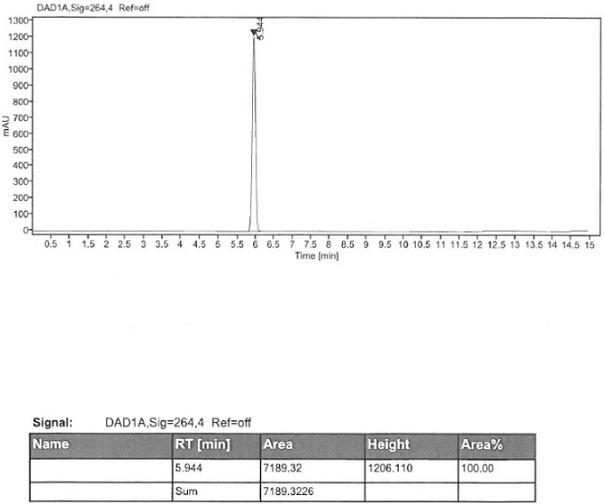

[0042] Add 50 g of (S)-2-amino-6-propionamido-4,5,6,7-tetrahydrobenzothiazole, 300 ml of tetrahydrofuran, and 20 g of sodium borohydride into the reaction flask. 94.5 g of boron trifluoride was added dropwise at a temperature of 10 degrees Celsius, and after the drop was completed, the temperature was raised to reflux for 2 hours of reaction. After cooling down to room temperature, dilute hydrochloric acid was added to terminate the reaction. Add 20% sodium hydroxide aqueous solution, adjust the pH to 14, add ethyl acetate for extraction, and separate layers. The organic layer was concentrated until 4-5V of solvent remained, then 2V of methanol was added, 0.75V of concentrated hydrochloric acid was added dropwise to form a salt, and the temperature was lowered to 10°C for crystallization. After filtration and drying, 60.3 g of pramipexole hydrochloride dihydrochloride monohydrate was obtained, with a molar yield of 89.9% and a purity of 99.92%.

[0043] Add 50g of pramipexol...

Embodiment 2

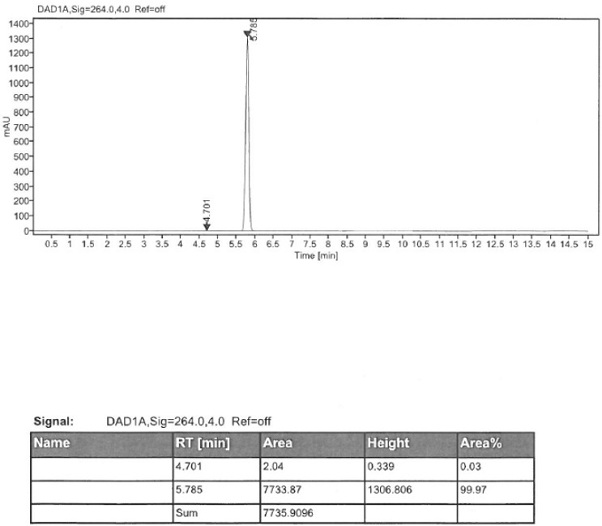

[0045] Add 50 g of (S)-2-amino-6-propionamido-4,5,6,7-tetrahydrobenzothiazole, 400 ml of tetrahydrofuran, and 24 g of sodium borohydride into the reaction flask. 113.4 g of boron trifluoride was added dropwise at a temperature of 10 degrees Celsius, and after the drop was completed, the temperature was raised to reflux for 2 hours of reaction. After cooling down to room temperature, dilute hydrochloric acid was added to terminate the reaction. Add 20% sodium hydroxide aqueous solution, adjust the pH to 14, add ethyl acetate for extraction, and separate layers. The organic layer was concentrated until 4-5V of solvent remained, and then 2V of methanol was added, and 0.8V of concentrated hydrochloric acid was added dropwise to form a salt, and the temperature was lowered to 10°C for crystallization. After filtration and drying, 61.5 g of pramipexole hydrochloride dihydrochloride monohydrate was obtained, with a molar yield of 91.7% and a purity of 99.91%.

[0046] Add 50g of pr...

Embodiment 3

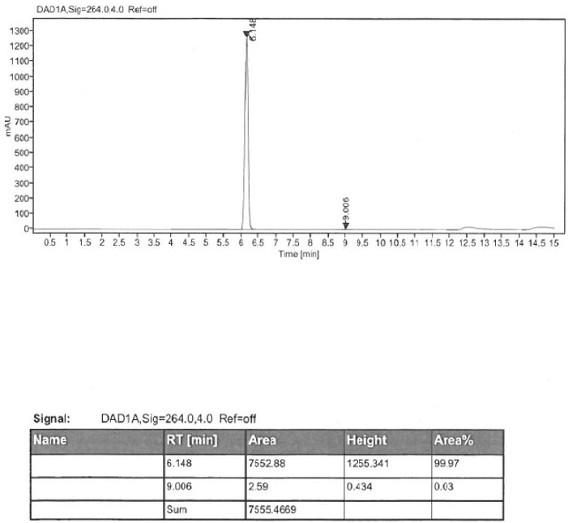

[0048] Add 50 g of (S)-2-amino-6-propionamido-4,5,6,7-tetrahydrobenzothiazole, 500 ml of tetrahydrofuran, and 22 g of sodium borohydride into the reaction flask. 104 g of boron trifluoride was added dropwise at a temperature of 10 degrees Celsius, and after the drop was completed, the temperature was raised to reflux for 2 hours of reaction. After cooling down to room temperature, dilute hydrochloric acid was added to terminate the reaction. Add 20% sodium hydroxide aqueous solution, adjust the pH to 14, add ethyl acetate for extraction, and separate layers. The organic layer was concentrated until 4-5V of solvent remained, and then 2V of methanol was added, and 0.8V of concentrated hydrochloric acid was added dropwise to form a salt, and the temperature was lowered to 10°C for crystallization. After filtration and drying, 61.1 g of pramipexole hydrochloride dihydrochloride monohydrate was obtained, with a molar yield of 91.1% and a purity of 99.91%.

[0049] Add 50g of pram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com