Ultrahigh-fluidity polypropylene melt-blown special material and preparation method thereof

A polypropylene melt-blown and fluidity technology, applied in the field of modified plastics, can solve the problems of unsatisfactory environmental protection of the preparation process, wide product molecular weight distribution, and unfavorable production of melt-blown cloth, so as to achieve no residue of other products, excellent spinning Silk performance, low ash effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

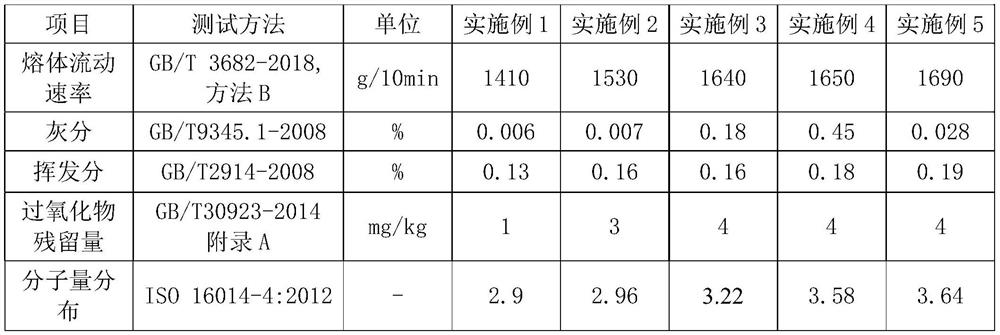

Examples

Embodiment 1

[0026] The special material for ultra-high fluidity polypropylene melt blown in this embodiment, the raw materials include the following components by weight: 99.4 parts of homopolypropylene resin, 0.4 parts of viscosity adjustment additive, 0.1 part of antioxidant, and 0.1 part of lubricant; The melt flow rate of the homopolypropylene resin is 0.5-5g / 10min.

[0027] In this embodiment, the viscosity adjusting aid is 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane, and the antioxidant is tetrakis[β-(3,5-di-tert- Butyl-4-hydroxyphenyl) propionate] pentaerythritol ester.

[0028] In this embodiment, the lubricant is paraffin. In this embodiment, the paraffin is replaced by microcrystalline paraffin, oleic acid amide, erucamide, ethylene bisstearamide, calcium stearate, hard One of zinc stearates, or a mixture of paraffin and microcrystalline paraffin, oleic acid amide, erucic acid amide, ethylene bisstearamide, calcium stearate, zinc stearate, all get qualified products.

[0029]...

Embodiment 2

[0034] The special material for ultra-high fluidity polypropylene melt blown in this embodiment, the raw materials include the following components by weight: 99.3 parts of homopolypropylene resin, 0.5 part of viscosity adjustment additive, 0.1 part of antioxidant, and 0.1 part of lubricant; The melt flow rate of the homopolypropylene resin is 0.5-5g / 10min.

[0035] In this embodiment, the viscosity adjusting aid is 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane, and the antioxidant is tetrakis[β-(3,5-di-tert- Butyl-4-hydroxyphenyl) propionate] pentaerythritol ester.

[0036] In this embodiment, the lubricant is oleic acid amide. In this embodiment, oleic acid amide is replaced by microcrystalline paraffin, paraffin, erucamide, ethylene bisstearamide, calcium stearate , zinc stearate, or a mixture of oleic acid amide and microcrystalline paraffin, paraffin, erucamide, ethylene bisstearamide, calcium stearate, zinc stearate, all qualified products .

[0037] Its preparation me...

Embodiment 3

[0042] The special material for ultra-high fluidity polypropylene melt blown in this embodiment, the raw materials include the following components by weight: 98.7 parts of homopolypropylene resin, 0.6 parts of viscosity adjustment additive, 0.1 part of antioxidant, 0.2 part of lubricant, 0.2 parts of nucleating agent, 0.2 parts of electret auxiliary agent; the melt flow rate of the homopolypropylene resin is 0.5-5g / 10min.

[0043] In this embodiment, the viscosity adjusting aid is di-tert-butyl peroxide. In this embodiment, di-tert-butyl peroxide is replaced by peroxy-2-ethylhexanoic acid tert-butyl One of esters, 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane, dicumylbenzene di-tert-butylperoxide, or replaced by di-tert-butylperoxide Compounds with peroxy-2-ethylhexanoic acid tert-butyl ester, 2,5-dimethyl-2,5-bis(peroxy-tert-butyl)hexane, bis-tert-butylperoxydiisopropylbenzene Mixtures were obtained as qualified products.

[0044] In this embodiment, the antioxidant is tetr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com