Method for resource utilization of waste copper adsorbent

An adsorbent and recycling technology, applied in the field of hazardous waste recycling, achieves the effect of easy operation, large industrial applicability and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: The method for resource utilization of the waste copper adsorbent is as follows:

[0025] 1. Synthesis of ZSM-5

[0026] (1) Mix 0.33g silica fume, 1.31g sodium silicate nonahydrate, 0.43g ammonium chloride, 0.24g tetrapropylammonium bromide and grind for 15min until the solid mixture becomes a paste;

[0027] (2) Transfer the paste to the reactor, and place the reactor at 160°C for 48 hours;

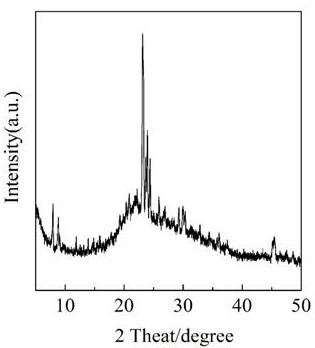

[0028] (3) After the reaction is completed, take out the reaction kettle to cool down, wash the reaction product with deionized water 5 times, and then dry it at 60°C overnight to obtain a solid white powder ZSM-5; the results are shown in figure 1 , the zeolite synthesized by tetrapropylammonium bromide has the crystal phase of ZSM-5; the main peak (2 = 7.9 o , 8.9 o , 23.1 o , 23.9 o ), which is consistent with the orthorhombic structure of ZSM-5; the synthesis of high-silicon ZSM-5 requires a higher templating agent, and TPA in tetrapropylammonium bromide ...

Embodiment 2

[0034] Embodiment 2: the method for resource utilization of this waste copper adsorbent is as follows:

[0035] 1. Synthesis of ZSM-5

[0036] (1) Mix 0.32g silica fume, 1.35g sodium silicate nonahydrate, 0.45g ammonium chloride, 0.25g tetrapropylammonium bromide and grind for 15min until the solid mixture becomes a paste;

[0037] (2) Transfer the paste to the reactor, and place the reactor at 170°C for 45 hours;

[0038] (3) After the reaction is completed, take out the reaction kettle to cool down, wash the reaction product with deionized water 5 times, and then dry it at 60°C overnight to obtain solid white powder ZSM-5;

[0039] 2. Preparation of nZVI / ZSM-5

[0040] (1) Add 0.5g ZSM-5 and 0.45g ferrous sulfate heptahydrate into a three-necked flask, add 100mL ethanol solution with a mass concentration of 30%, and stir for 25min to obtain a mixed solution; while stirring, add 0.5mol of sodium borohydride / L ratio, drop the sodium borohydride solution into the three-necked...

Embodiment 3

[0044] Embodiment 3: The method for resource utilization of the waste copper adsorbent is as follows:

[0045] 1. Synthesis of ZSM-5

[0046] (1) Mix 0.35g silica fume, 1.34g sodium silicate nonahydrate, 0.5g ammonium chloride, 0.3g tetrapropylammonium bromide and grind for 15min until the solid mixture becomes a paste;

[0047] (2) Transfer the paste to the reactor, and place the reactor at 150°C for 50 hours;

[0048] (3) After the reaction is completed, take out the reaction kettle to cool down, wash the reaction product with deionized water 5 times, and then dry it at 60°C overnight to obtain solid white powder ZSM-5;

[0049] 2. Preparation of nZVI / ZSM-5

[0050] (1) Add 0.5g ZSM-5 and 0.225g ferrous sulfate heptahydrate into a three-necked flask, add 100mL ethanol solution with a mass concentration of 30%, and stir for 25min to obtain a mixed solution; while stirring, add 0.5mol of sodium borohydride / L ratio, drop the sodium borohydride solution into the three-necked...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com