Carbon dioxide carbonized regenerated water permeable brick and preparation process thereof

A carbon dioxide and preparation technology, applied in the field of solid waste recycling, can solve the problems of long burning time of energy, consumption of wood, unfavorable sustainable development, etc., to reduce the emission of carbon dioxide and dust and other pollutants, and save resources and energy consumption reduction, to achieve the effect of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

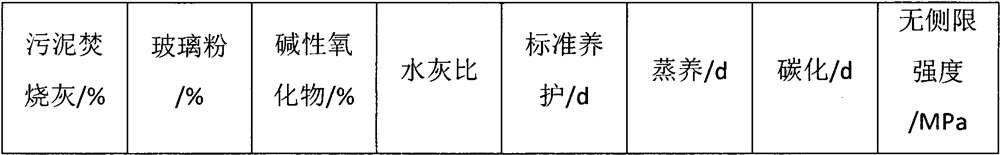

[0043] In order to demonstrate the action mechanism and usability of the cementing material used in the present invention, this example shows the results of the compressive strength of the clean slurry test block under the condition of no coarse-grained aggregate and curing conditions. The clean slurry test block is a cube with a side length of 40mm, and the sludge incineration ash is 10%, waste glass powder 70%, and alkaline oxide 20%, and the alkaline oxide is by magnesium oxide: calcium oxide: the mass ratio of sodium oxide is 4:4:2 for mixing, the water-cement ratio is 0.4-0.5. The stirred mixed slurry was injected into the cube module, and vibrated on the vibration table for 2 minutes to discharge the air bubbles in the sample. Afterwards, the curing was carried out in three ways: indoor standard curing, steam curing and carbonization curing. After curing, the unconfined compressive strength test was carried out, and the average value of the test strength was taken as the...

Embodiment 2

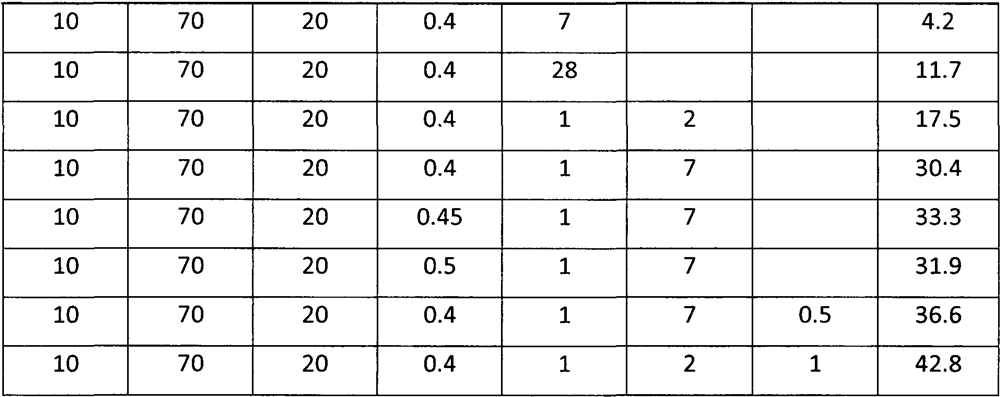

[0048] This example considers the influence of the proportion of alkaline materials and curing conditions on the strength, and shows the results of the compressive strength of the clean slurry test block without coarse aggregates. The clean slurry test block is a cube test block with a side length of 40 mm, the sludge incineration ash is 10%, the waste glass powder is 70%, and the basic oxide is 20%. The basic oxide is different according to the difference of magnesium oxide: calcium oxide: sodium oxide The mass ratio is mixed, and the water-cement ratio is 0.45. The stirred mixed slurry was injected into the cube module, and vibrated on the vibration table for 2 minutes to discharge the air bubbles in the sample. Afterwards, the curing was carried out in three ways: indoor standard curing, steam curing and carbonization curing. After curing, the unconfined compressive strength test was carried out, and the average value of the test strength was taken as the final result. The ...

Embodiment 3

[0052] In this embodiment, the influence of discarded coarse aggregates on the strength of the test block is considered. The permeable test block is a cubic test block with a side length of 150mm. The test block is prepared according to the mass percentage of each component. The sludge incineration ash is 20%, the marine bottom mud is 5%, and the waste concrete particles (average particle size 5mm) are 30%. 10mm long polypropylene fiber 1%, waste glass powder 24%, alkaline hydroxide 20%, alkaline oxide is to mix by magnesium hydroxide: calcium hydroxide: the mass ratio of sodium hydroxide 4: 2: 4 , the water-cement ratio is 0.45. Pour the stirred mixture into the cube module and vibrate on the vibrating table for 2 minutes to discharge the air bubbles in the sample. After that, according to the combination of indoor standard curing for 1 day, steam curing for 3 days and carbonization curing for 1 day, respectively, the unconfined compressive strength test is carried out after...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com