Preparation method of extreme-micropore-enriched carbon material based on carboxylation anchoring effect

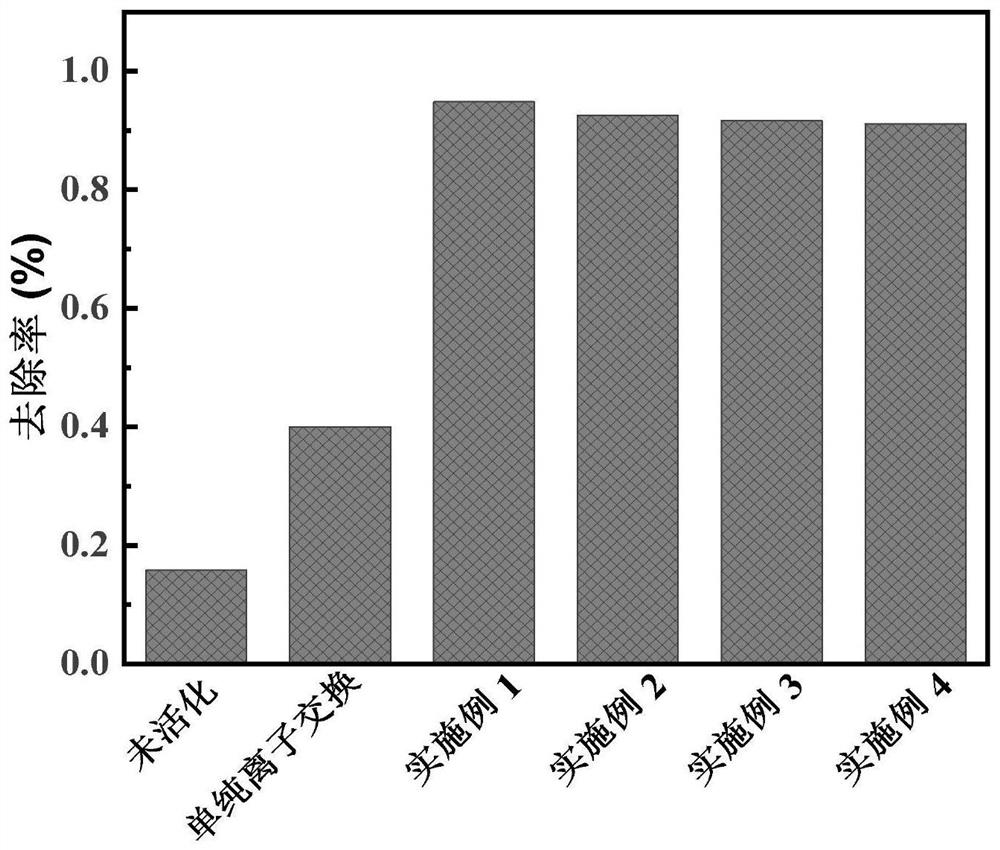

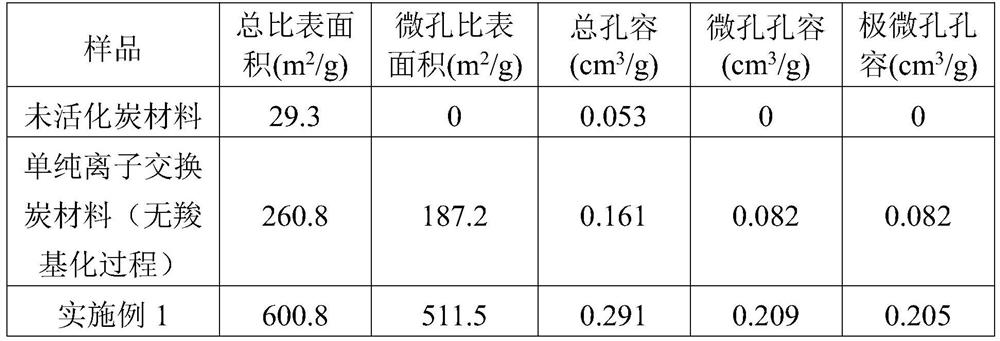

A microporous carbon and carboxylation technology, applied in chemical instruments and methods, separation methods, inorganic chemistry, etc., can solve the problems of irregular pore size, collapse of extremely micropores, environmental pollution, etc., and achieve uniform pore size distribution and pore structure. The effect of orderly and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation method of extremely microporous carbon material, comprising the steps of:

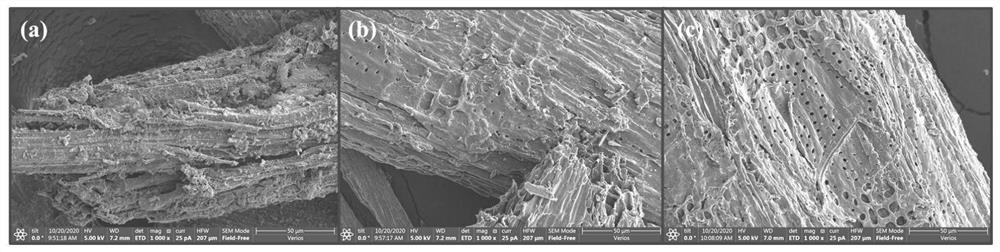

[0028] (1) Pretreating the eucalyptus, washing, drying and crushing to obtain eucalyptus chips.

[0029] (2) Immerse 10g of eucalyptus sawdust in 50mL of 0.6mol / L citric acid solution for 0.5h, then dry in a blast drying oven at 50°C for 24h, and react the dried material at 120°C for 90min, then The material was washed with water to neutrality, and the carboxylated material was obtained after drying.

[0030] (3) At a temperature of 80°C, immerse the carboxylated material in 50 mL of 2mol / L KOH solution for ion exchange for 15 hours. The metal ions are evenly distributed on the surface of the material through the anchoring effect of the carboxyl group, and then washed to remove the excess Alkaline to neutral and dry.

[0031] (4) The dried material was placed in a tube furnace under N 2 Under the atmosphere, the temperature was raised to 800°C at a rate of 5°C / min, and kept at 8...

Embodiment 2

[0033] A preparation method of extremely microporous carbon material, comprising the steps of:

[0034] (1) Pretreating the eucalyptus, washing, drying and crushing to obtain eucalyptus chips.

[0035] (2) Immerse 10g of eucalyptus sawdust in 50mL of 0.6mol / L citric acid solution for 24h, then dry it in a blast drying oven at 50°C for 24h, and react the dried material for 90min at 120°C, and then The material was washed with water until neutral, and the carboxylated material was obtained after drying.

[0036] (3) At a temperature of 80°C, immerse the carboxylated material in 50 mL of 2mol / L KOH solution for ion exchange for 2 hours, and the metal ions are evenly distributed on the surface of the material through the anchoring effect of the carboxyl group, and then washed to remove excess Alkaline to neutral and dry.

[0037] (4) The dried material was placed in a tube furnace under N 2 Under the atmosphere, the temperature was raised to 800°C at a rate of 5°C / min, and kept...

Embodiment 3

[0039] (1) Pretreating the eucalyptus, washing, drying and crushing to obtain eucalyptus chips.

[0040] (2) Immerse 10g of eucalyptus sawdust in 50mL 2mol / L tartaric acid solution for 0.5h, then dry it in a blast drying oven at 100°C for 24h, and react the dried material for 90min at 100°C, then put the material Wash with water until neutral, and obtain carboxylated material after drying.

[0041] (3) At a temperature of 150°C, immerse the carboxylated material in 50 mL of 2mol / L LiOH solution for ion exchange for 24 hours, and the metal ions are evenly distributed on the surface of the material through the anchoring effect of the carboxyl group, and then washed to remove the excess Alkaline to neutral and dry.

[0042] (4) The dried material was placed in a tube furnace under N 2 Under the atmosphere, the temperature was raised to 900°C at a rate of 5°C / min, and kept at 900°C for 90 minutes for ion exchange reaction. After naturally cooling down to room temperature, the obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com