High-entropy wave-absorbing carbide ceramic powder material as well as preparation method and application thereof

A technology of ceramic powder and carbide, which is applied to high-entropy carbide ceramics with wide absorption band, preparation, high-entropy absorbing carbide ceramic powder material, high purity, and strong absorbing performance, which can solve the problem of narrow absorption band , low density, high temperature stability, and low absorption strength, etc., to achieve the effect of wide absorption frequency band, wide absorption frequency band, and strong wave absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] According to the second aspect of the present invention, there is provided a method for preparing a high-entropy absorbing carbide ceramic powder material, which is used to prepare the high-entropy absorbing carbide ceramic powder material described in the first aspect, comprising the following steps :

[0024] Step 1, selecting more than five kinds of transition metal oxides, mixing transition metal oxides and carbon black in the presence of a mixed medium to obtain a uniformly mixed slurry;

[0025] In step 2, the slurry obtained in step 1 is dried, sieved to obtain a mixed powder, and the mixed powder is calcined to obtain a carbide ceramic powder material.

[0026] In a preferred embodiment of the present invention, in step 1, the mixed medium is volatile organic matter, preferably absolute ethanol.

[0027] In a preferred embodiment of the present invention, in step 2, the calcination temperature is 1900°C-2100°C, the calcination time is 1-3h, and the calcination ...

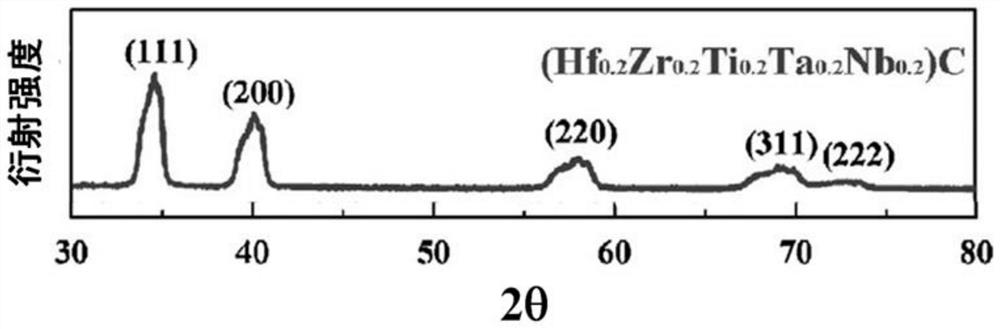

Embodiment 1

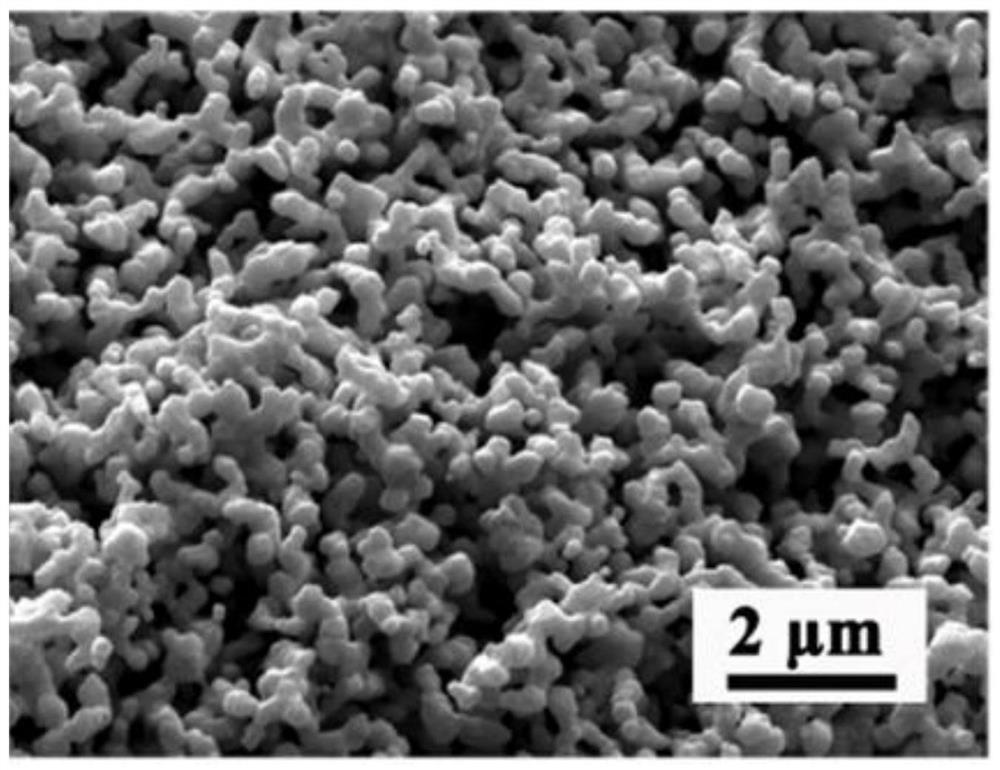

[0036] Choose TiO 2 , ZrO 2 , HfO 2 , Nb 2 O 5 , Ta 2 O 5 And carbon black as raw material, by mole percentage, weigh 5mol% TiO 2 , 5mol% ZrO 2 , 5mol% HfO 2 , 2.5mol%Nb 2 O 5 , 2.5 mol% Ta 2 O 5 , 80mol% carbon black, mixed in a ball mill tank, the mixing time was 6 hours, and the mixing medium was anhydrous ethyl alcohol to obtain a slurry; the obtained slurry was filtered and dried, and passed through a 120-mesh sieve to obtain a mixture Powder, put the dried powder into a high-temperature furnace for calcination, the calcination temperature is 1900°C, the calcination time is 2 hours, and the vacuum degree is 8Pa to obtain high-entropy wave-absorbing carbide ceramic powder.

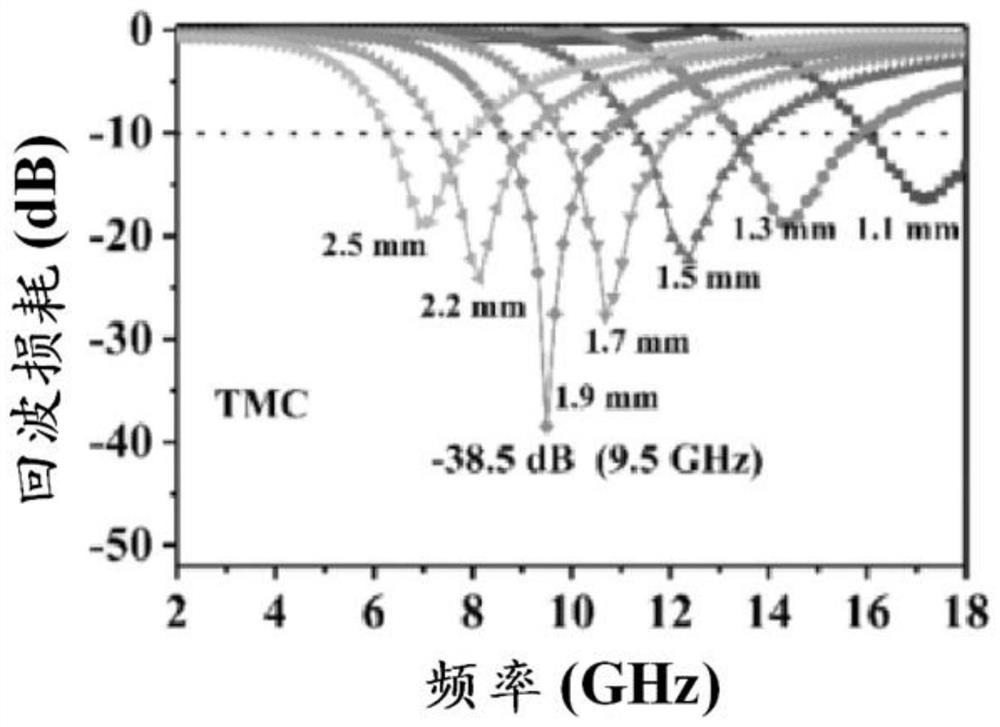

[0037]The purity of the ceramic powder material is 100wt%, and the average particle size is 0.3 microns. Using the Agilent N5244A vector network analyzer, the maximum absorption loss at the frequency of 2-18GHz is 38.5dB, and the maximum absorption frequency is when the reflectivity is belo...

Embodiment 2

[0039] This embodiment is consistent with embodiment 1, the only difference is: with TiO 2 , ZrO 2 , HfO 2 , V 2 o 5 、 Ta 2 o 5 And carbon black as raw material, by mole percentage, weigh 5mol% TiO 2 , 5mol% ZrO 2 , 5mol% HfO 2 , 2.5mol% V 2 o 5 , 2.5 mol% Ta 2 o 5 , 80mol% carbon black. The calcination temperature is 1950° C., the calcination time is 1.5 hours, and the vacuum degree is 10 Pa. The obtained high-entropy ceramic powder material has a purity of 100wt%, an average particle size of 0.4 microns, an absorption loss of 30dB at a frequency of 2-18GHz, and a maximum absorption frequency bandwidth of 3.2GHz when the reflectivity is below -10dB.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com