Compound, preparation method thereof and quantum dot light-emitting diode

A technology for quantum dot luminescence and compound, which is applied in chemical instruments and methods, luminescent materials, semiconductor/solid-state device manufacturing, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

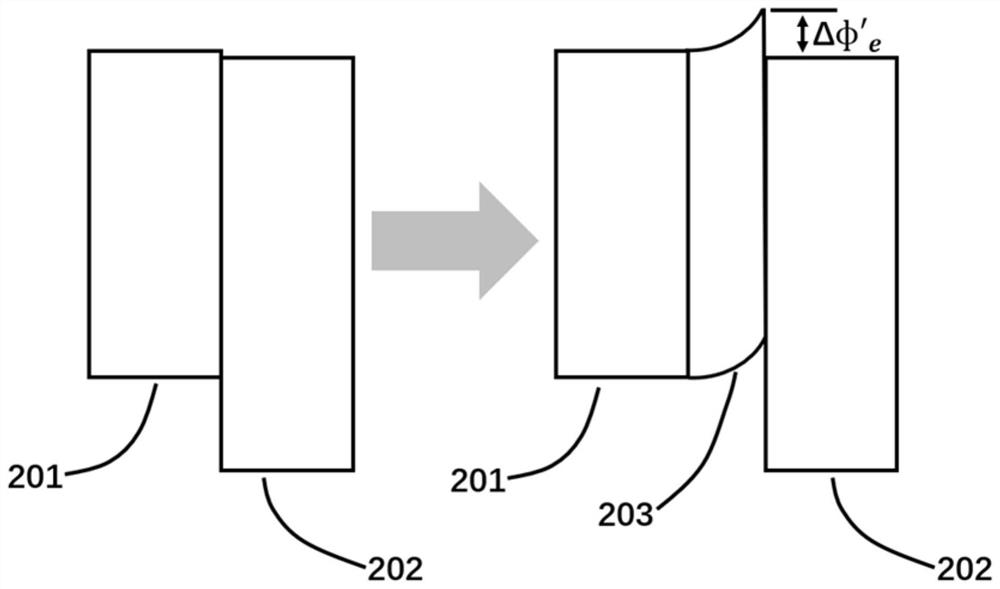

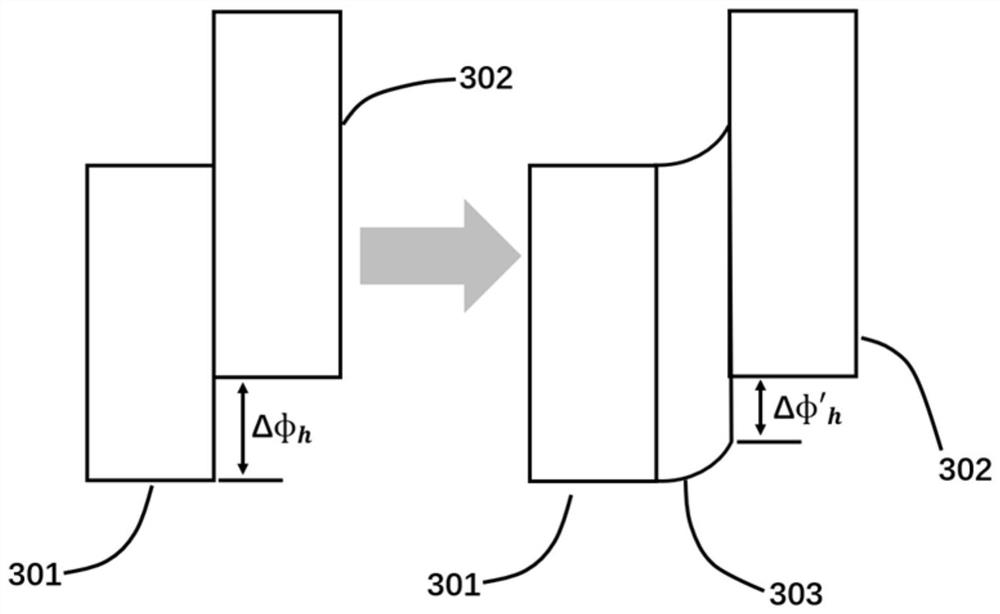

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] A preparation method of a compound, comprising the following steps:

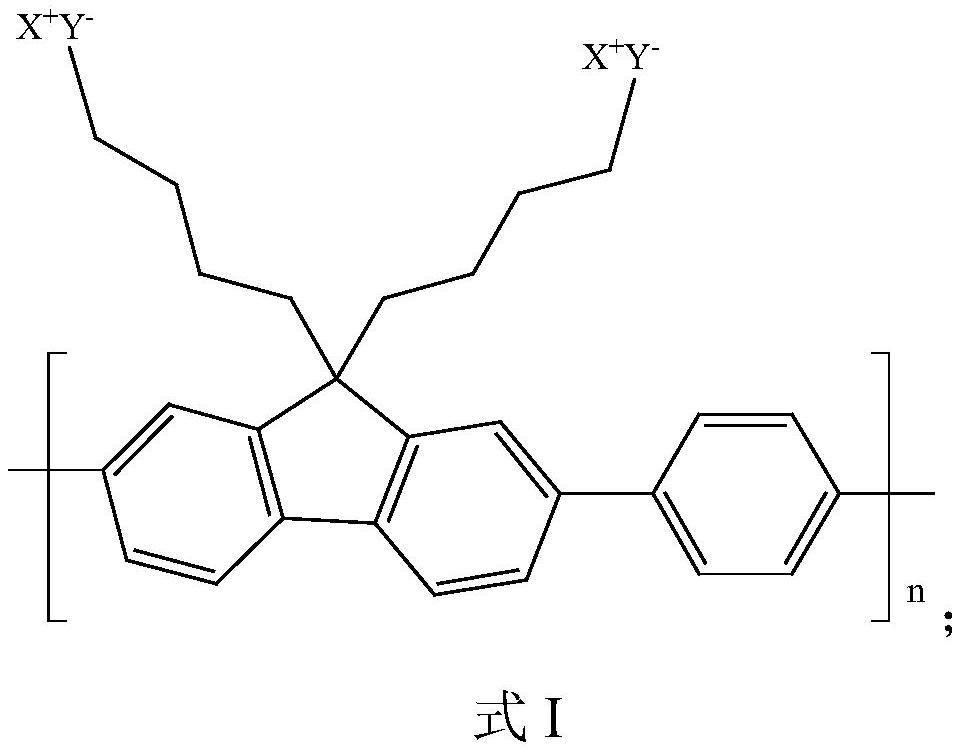

[0043] will structure as Compound A, the structural formula is The compound B and the palladium catalyst are mixed, and the solvent and the alkaline solution are added to obtain the mixture; wherein, the X + is a metal cation; the Y - is an anion connected to an alkyl side chain; the R 1 is a halogen, the R 2 is a halogen, the R 3 is a borate ester group, the R 4 is a borate group;

[0044] The mixture was reacted at 80-120°C for 20h-28h to generate a compound having the structure shown in formula I:

[0045]

[0046] Wherein, the n is a positive integer of 100-300.

[0047] The compound A includes but not limited to 2,7-dibromo-9,9-bis(6-sulfonate butyl)disodium fluoride, 2,7-dibromo-9,9-bis(6-bromobutyl) base) disodium fluorene, 2,7-dibromo-9,9-bis(6-sulfonate butyl)dipotassium fluorene or 2,7-dibromo-9,9-bis(6-bromobutyl) Dipotassium fluorene.

[0048] The compound B is 1,4-phenylen...

Embodiment 1

[0068] The present embodiment provides a kind of preparation method of sodium polyfluorene cophenylene sulfonate (PFP-Na), comprises the following steps:

[0069] (1) Take 300mg of 2,7-dibromo-9,9-bis(6-sulfonate butyl)disodium fluoride, 135mg of 1,4-phenylene diboronic acid ester and 20mg of tetrakis(triphenylene) Phosphine) palladium, placed in the there-necked flask;

[0070] (2) Add 4ml of dimethylformamide, 0.5ml of toluene, and 2ml of 2M aqueous sodium carbonate solution into the there-necked flask;

[0071] (3) Vacuumize the there-necked bottle to remove the gas inside;

[0072] (4) stirring and heating to 100° C., and reacting for 24 hours;

[0073] (5) Add excess acetone and centrifuge, take the precipitate and dissolve it in deionized water, and then dialyze;

[0074] (6) Finally, the product is freeze-dried to obtain sodium polyfluorene co-phenylene sulfonate (PFP-Na), the structure of which is as follows:

[0075]

[0076] Among them, the X + for Na + ;

...

Embodiment 2

[0080] This embodiment provides a positive QLED device and its preparation method, the steps are as follows:

[0081] (1) Clean the ITO glass substrate sequentially with lotion, deionized water, and isopropanol for 10 minutes, then dry it and treat it with UV-ozone for 15 minutes;

[0082] (2) Deposit 30nm PEDOT:PSS as a hole injection layer on the ITO glass substrate by solution method, and then anneal in air at 150°C for 15 minutes;

[0083] (3) Transfer the above substrate to a glove box filled with nitrogen, deposit 30nm TFB as a hole transport layer on the hole injection layer by solution method, and then anneal at 150°C for 30 minutes;

[0084] (4) Deposit 25nm CdSe / ZnS quantum dots on the hole transport layer by solution method as the quantum dot light-emitting layer, and then anneal at 100°C for 15 minutes;

[0085] (5) Deposit the PFP-Na obtained in Example 1 on the quantum dot luminescent layer as an interface modification layer by solution method, the thickness of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com