A kind of manganese dioxide-melamine formaldehyde resin double-shell composite phase change material and preparation method thereof

A composite phase change material, melamine technology, applied in chemical instruments and methods, manganese oxide/manganese hydroxide, microsphere preparation, etc., can solve problems such as poor photothermal performance, easy aggregation of nanoparticles, and difficulty in achieving additive effects. Achieve the effects of good leak-proof performance, high photothermal performance, and good thermal cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

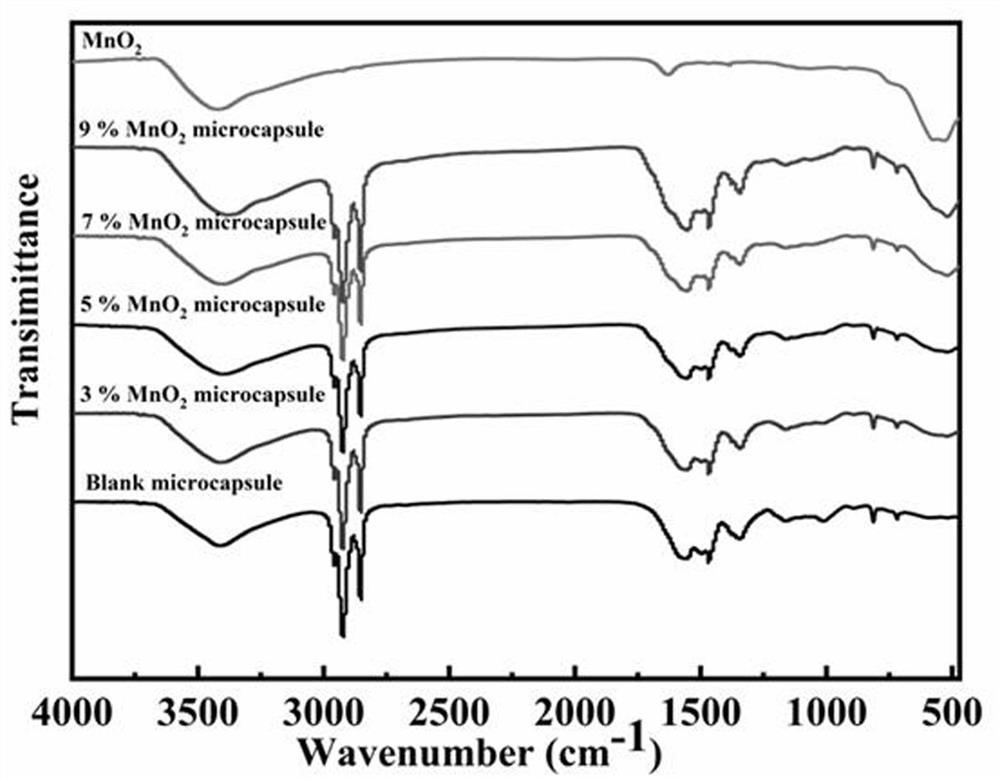

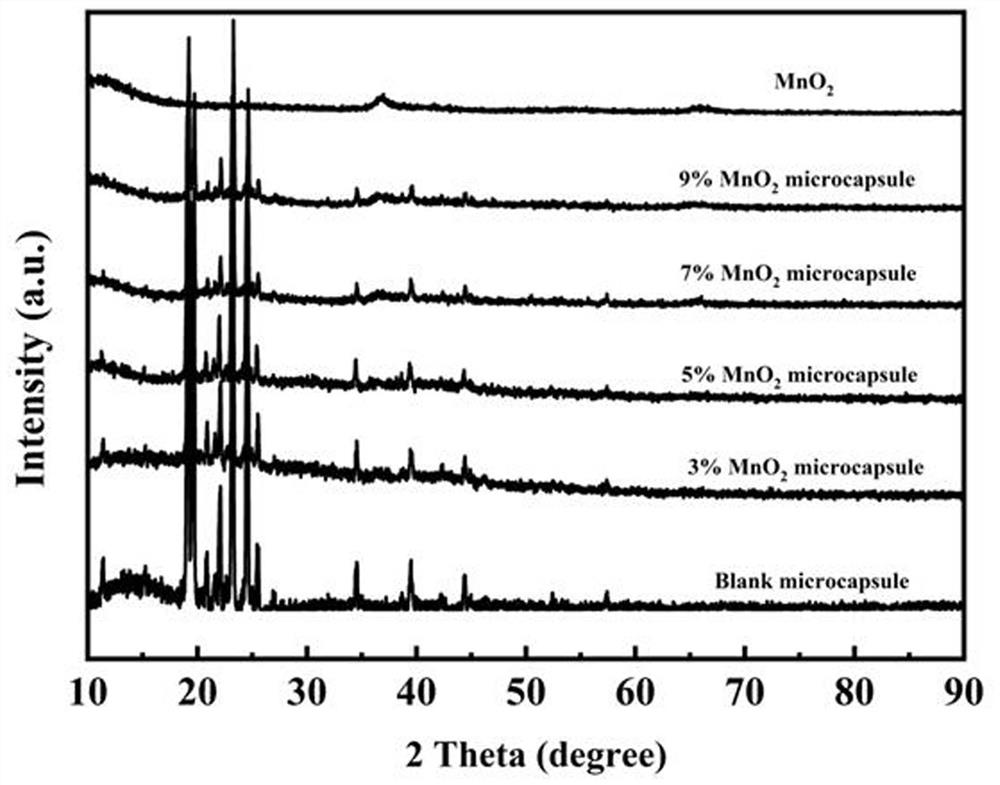

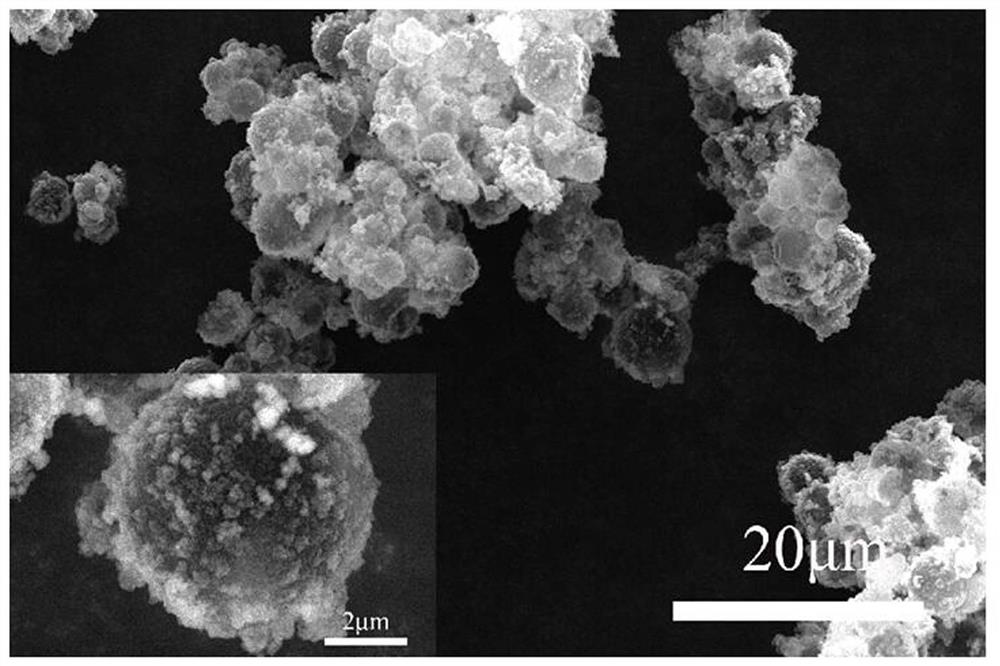

[0055] A kind of preparation method of manganese dioxide-melamine formaldehyde resin double-shell composite phase change material:

[0056] Step 1) Pretreatment of raw materials, weigh 6g of melamine, 10ml of formaldehyde, and 10ml of deionized water in a single-necked flask, stir and mix evenly at room temperature to obtain solution A, and then dropwise add triethanolamine solution with a volume fraction of 50% to adjust the pH value to 9, then stirred at 70°C for 1 hour for prepolymerization to obtain a prepolymer, and another 25 g of n-octadecane and 7.5 g of styrene maleic anhydride, wherein the styrene maleic anhydride was first prepared as mass Styrene maleic anhydride solution with a fraction of 5% is emulsified under the conditions that the rotation speed is 2500r / min, the emulsification temperature is 70, and the emulsification time is 2 hours to obtain an emulsion;

[0057] Step 2) Preparation of microcapsules. Under the conditions of temperature 70°C and rotational ...

Embodiment 2

[0079] A method for preparing a manganese dioxide-melamine formaldehyde resin double-shell composite phase change material, the steps not specifically described are the same as in Example 1, except that the quality of manganese sulfate in the step 3 is 0.065g, 0.0167 The volume of g / mL potassium permanganate is 15ml, and the resulting sample is named 3wt% MnO 2 microcapsule.

[0080] In order to prove the phase change properties of manganese dioxide-melamine formaldehyde resin double-shell composite phase change materials, differential scanning calorimetry (DSC) tests were carried out. The result is as Figure 4 As shown, the melting temperature of the manganese dioxide-melamine formaldehyde resin double-shell composite phase change material is 29.70°C, and the crystallization temperature is 23.50°C; the measured latent heat of phase change is 152.71J / g and 151.74J / g.

[0081] In order to prove the photothermal conversion effect of manganese dioxide-melamine formaldehyde re...

Embodiment 3

[0083] A method for preparing a manganese dioxide-melamine formaldehyde resin double-shell composite phase change material, the steps not specifically described are the same as in Example 1, except that the quality of manganese sulfate in the step 3 is 0.10g, 0.0167 The volume of g / mL potassium permanganate is 25ml, and the resulting sample is named 5wt% MnO 2 microcapsule.

[0084] In order to prove the phase change properties of manganese dioxide-melamine formaldehyde resin double-shell composite phase change materials, differential scanning calorimetry (DSC) tests were carried out. The result is as Figure 4 As shown, the melting temperature of the manganese dioxide-melamine formaldehyde resin double-shell composite phase change material is 29.64°C, and the crystallization temperature is 23.61°C; the measured latent heat of phase change is 142.13J / g and 141.44J / g.

[0085] In order to prove the photothermal conversion effect of manganese dioxide-melamine formaldehyde res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com