Preparation method of light-enhanced supercapacitor electrode

A supercapacitor and electrode technology, which is applied in the field of preparation of light-enhanced supercapacitor electrodes, can solve the problems of affecting the performance of supercapacitor electrodes, limited electrochemical performance enhancement, and high cost of noble metal doping, and achieves excellent electrochemical performance and good mechanical properties. Performance, Effect of High Conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1, the present invention provides a kind of technical scheme: a kind of preparation method of the supercapacitor electrode material with light enhancing effect, comprises the following steps:

[0028] S1. Cut the foamed copper into 1cm*3cm, put it into 1mol / L hydrochloric acid and sonicate it for 10 minutes, take it out and wash it with deionized water 3 times until the hydrochloric acid residue is cleaned, then put it in acetone and sonicate it for 10 minutes, and then Sonicate 3 times with absolute ethanol and deionized water respectively, and dry the copper foam in a vacuum oven at 50°C to complete the pretreatment;

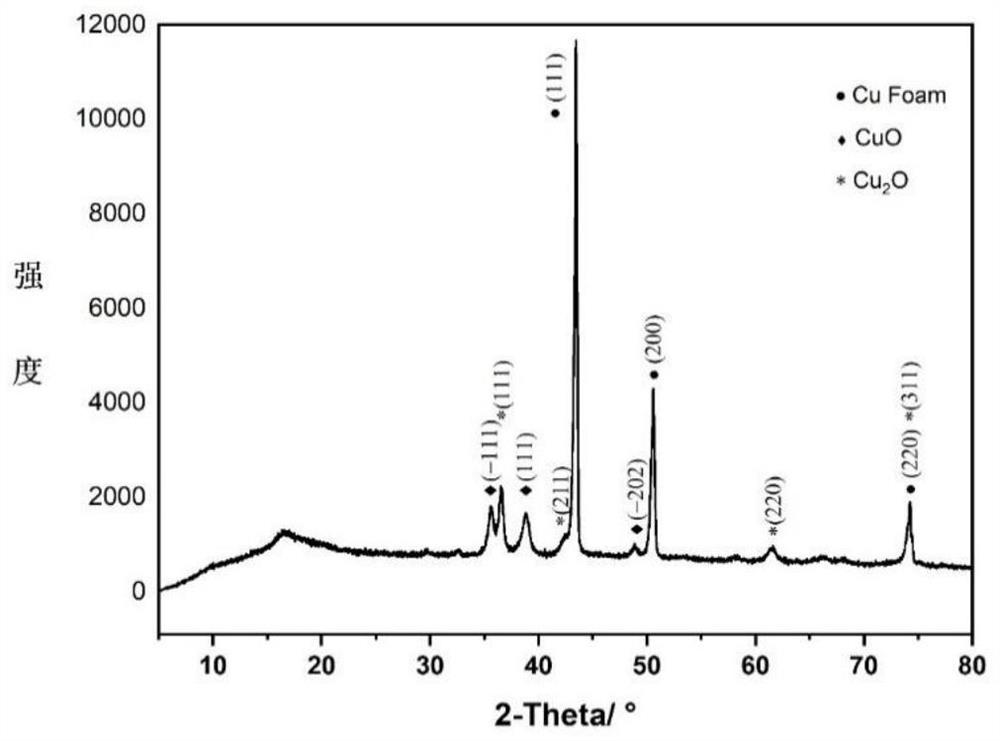

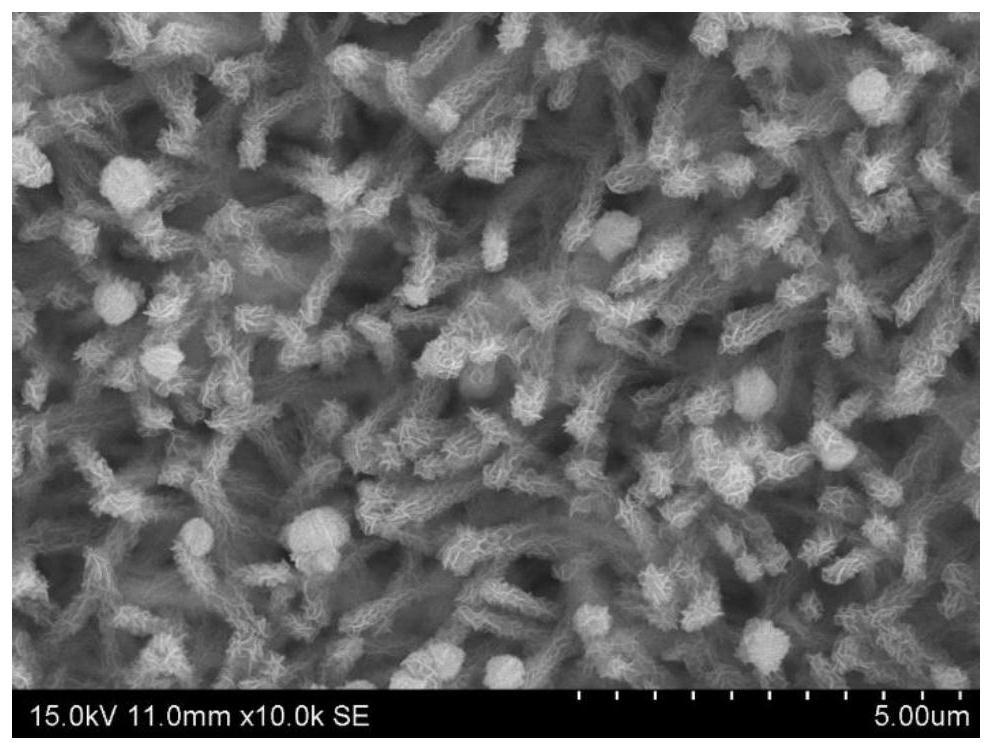

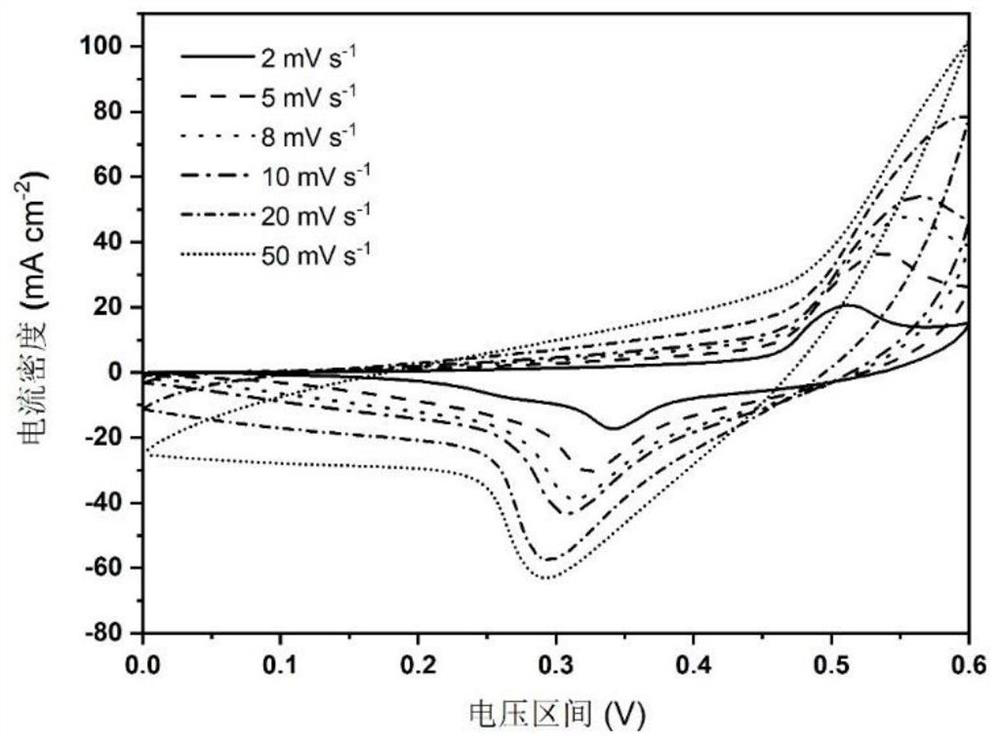

[0029] S2, placing the pretreated foamed copper in an alkaline ammonium persulfate solution, specifically a mixed aqueous solution of sodium hydroxide and ammonium persulfate with a molar ratio of 200:1, wherein the concentration of sodium hydroxide is 2.7mol / L, over The concentration of ammonium sulfate is 0.13mol / L, react for 25min, and the...

Embodiment 2

[0039] Embodiment 2: a kind of preparation method of the supercapacitor electrode material with light enhancing effect, comprises the following steps:

[0040] S1. Cut the foamed copper into 1cm*3cm, put it into 0.5mol / L hydrochloric acid and sonicate it for 10 minutes, take it out and wash it with deionized water for 3 times, then put it in acetone and sonicate it for 10 minutes. Finally, use the foamed copper separately Sonicate 3 times with absolute ethanol and deionized water, and dry in a vacuum oven at 50°C;

[0041] S2, placing the pretreated foamed copper in an alkaline ammonium persulfate solution, specifically a mixed aqueous solution of sodium hydroxide and ammonium persulfate with a molar ratio of 200:1, wherein the concentration of sodium hydroxide is 2.7mol / L, over The concentration of ammonium sulfate was 0.13mol / L, reacted for 25min, and then ultrasonicated three times with absolute ethanol and deionized water respectively, and dried in a drying oven at 50°C to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com