Electrolyte of negative-electrode-free secondary lithium battery, negative-electrode-free secondary lithium battery and formation process

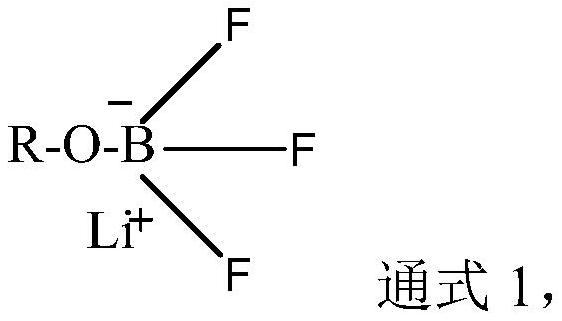

A secondary lithium battery and electrolyte technology, applied in secondary batteries, battery electrodes, secondary battery repair/maintenance, etc., can solve the problems of poor high temperature performance, low room temperature conductivity, etc. The effect of high conductivity and broadening the electrochemical stability window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

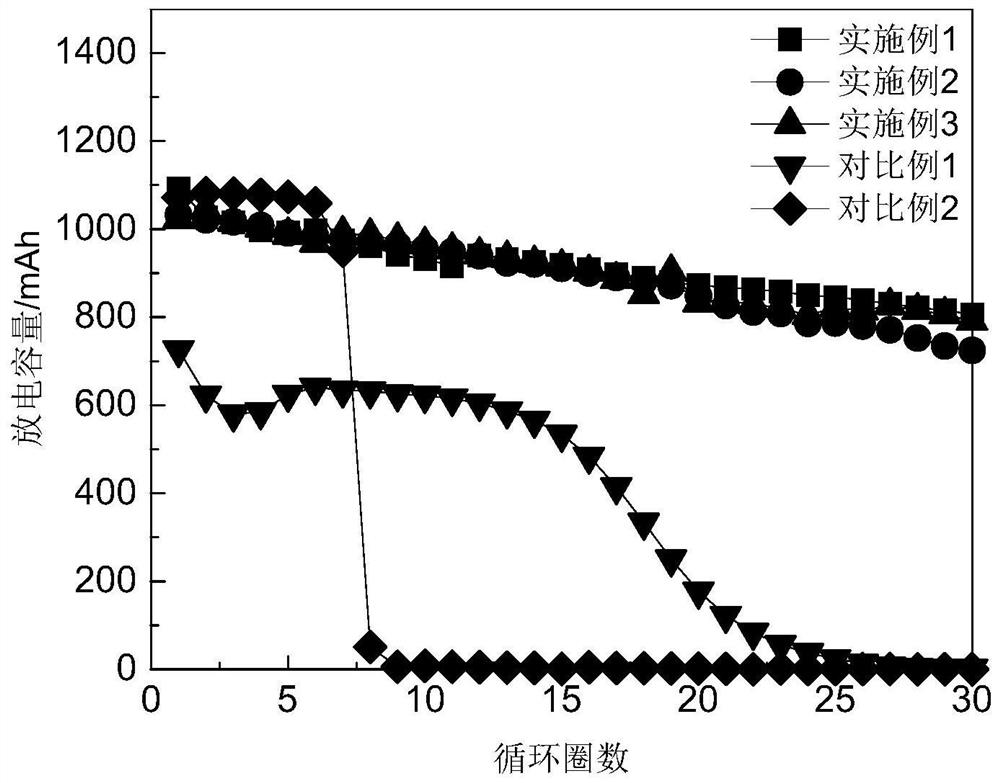

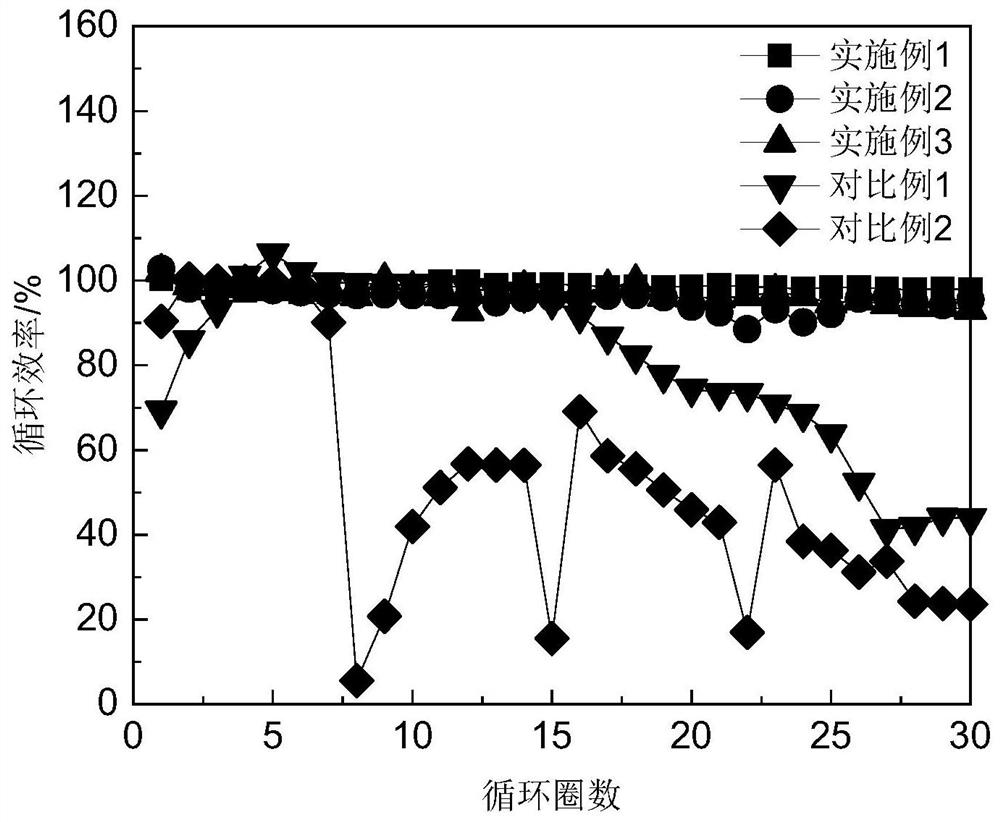

Embodiment 1

[0040] a. The manufacturing steps of the battery are briefly described as follows: lithium nickel aluminum cobalt oxide (NCA) is mixed with conductive carbon black (Super P), carbon nanotube (CNT), and polyvinylidene fluoride in a weight ratio of 93:2:2:3 Finally, add N-methylpyrrolidone and stir evenly to prepare positive electrode slurry. According to one side 27mg / cm 2 Coated with a surface density of 100 degrees Celsius for 12 hours in vacuum, then rolled and cut to make positive electrode sheets; using 10 μm copper foil as the negative electrode current collector, ultrasonically cleaned the copper foil in 1% nitric acid aqueous solution for 3 minutes to remove the oxide layer and dust impurities. Clean the acid-treated copper foil with absolute ethanol, dry it after cleaning. Carbon nanotubes with a thickness of 1 μm were coated on both sides of the copper foil, dried at room temperature, and then cut to form negative electrodes. The positive and negative plates are se...

Embodiment 2

[0044] a. The manufacturing steps of the battery are briefly described as follows: lithium nickel aluminum cobalt oxide (NCA) is mixed with conductive carbon black (Super P), carbon nanotube (CNT), and polyvinylidene fluoride in a weight ratio of 93:2:2:3 Finally, add N-methylpyrrolidone and stir evenly to prepare positive electrode slurry. According to one side 27mg / cm 2 Coated with a surface density of 100 degrees Celsius for 12 hours in vacuum, then rolled and cut to make a positive electrode sheet; using 24 μm copper foil as the negative electrode current collector, the copper foil was ultrasonically cleaned in 1% nitric acid aqueous solution for 3 minutes to remove the oxide layer and dust impurities. Clean the acid-treated copper foil with absolute ethanol, dry it after cleaning. Coated acetylene black with a thickness of 1 μm on both sides of the copper foil, dried at room temperature, and then cut to make negative electrodes. The positive and negative plates are sep...

Embodiment 3

[0048] a. The production steps of the battery are briefly described as follows: After mixing lithium nickel aluminum cobalt oxide (NCA) with conductive carbon black (Super P) and polyvinylidene fluoride in a weight ratio of 95:2:3, add N-methylpyrrolidone, Stir evenly to make positive electrode slurry. According to one side 27mg / cm 2 Coated with a surface density of 100 degrees Celsius for 12 hours in vacuum, then rolled and cut to make positive electrode sheets; using 10 μm copper foil as the negative electrode current collector, ultrasonically cleaned the copper foil in 1% nitric acid aqueous solution for 3 minutes to remove the oxide layer and dust impurities. Clean the acid-treated copper foil with absolute ethanol, dry it after cleaning. Carbon nanotubes with a thickness of 1 μm were coated on both sides of the copper foil, dried at room temperature, and then cut to form negative electrodes. The positive and negative plates are separated by a polypropylene (PP) ceramic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com