A kind of high-efficiency and environment-friendly mulch film with weed-killing and insect-killing effects and preparation method thereof

An environmentally friendly and effective technology, which is applied in the direction of weed eradication equipment, botanical equipment and methods, and devices for catching or killing insects, can solve the problems of refractory degradation, low production efficiency, and difficult processing, and achieve good results. Weeding and insecticidal effect, improvement of weeding and insecticidal effect, effect of compatibility of protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

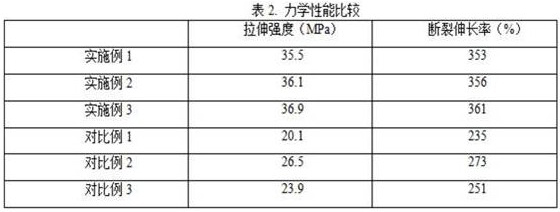

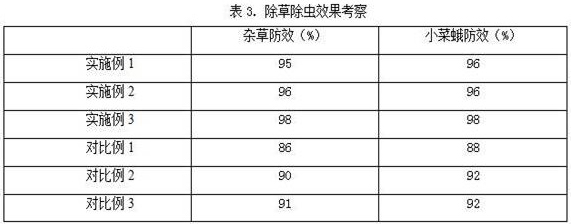

Embodiment 1

[0032] A method for preparing a high-efficiency and environment-friendly mulch film with weed-killing and insect-killing effects. First, mix herbicides and insecticides to make microcapsules, then mix the microcapsules with biodegradable materials, and blow film to obtain the mulch film wherein, the microcapsules are prepared by the following method: first use rapeseed oil as the oil phase, then mix starch octenyl succinate and sodium carboxymethyl cellulose aqueous solution to make the water phase, and then oil-soluble or water-soluble pesticides, insecticides, correspondingly added to the oil phase or water phase and stirred to mix, and finally emulsified by stirring, high-pressure homogenization, drying, that is, microcapsules; the biodegradable material is the use of fresh corn Stalk juice is used to modify sludge powder to obtain modified sludge powder, and then the modified sludge powder is mixed with polyvinyl alcohol partially modified soybean meal and epichlorohydrin. ...

Embodiment 2

[0049] A method for preparing a high-efficiency and environment-friendly mulch film with weed-killing and insect-killing effects. First, mix herbicides and insecticides to make microcapsules, then mix the microcapsules with biodegradable materials, and blow film to obtain the mulch film wherein, the microcapsules are prepared by the following method: first use rapeseed oil as the oil phase, then mix starch octenyl succinate and sodium carboxymethyl cellulose aqueous solution to make the water phase, and then oil-soluble or water-soluble pesticides, insecticides, correspondingly added to the oil phase or water phase and stirred to mix, and finally emulsified by stirring, high-pressure homogenization, drying, that is, microcapsules; the biodegradable material is the use of fresh corn Stalk juice is used to modify sludge powder to obtain modified sludge powder, and then the modified sludge powder is mixed with polyvinyl alcohol partially modified soybean meal and epichlorohydrin. ...

Embodiment 3

[0066] A method for preparing a high-efficiency and environment-friendly mulch film with weed-killing and insect-killing effects. First, mix herbicides and insecticides to make microcapsules, then mix the microcapsules with biodegradable materials, and blow film to obtain the mulch film wherein, the microcapsules are prepared by the following method: first use rapeseed oil as the oil phase, then mix starch octenyl succinate and sodium carboxymethyl cellulose aqueous solution to make the water phase, and then oil-soluble or water-soluble pesticides, insecticides, correspondingly added to the oil phase or water phase and stirred to mix, and finally emulsified by stirring, high-pressure homogenization, drying, that is, microcapsules; the biodegradable material is the use of fresh corn Stalk juice is used to modify sludge powder to obtain modified sludge powder, and then the modified sludge powder is mixed with polyvinyl alcohol partially modified soybean meal and epichlorohydrin. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com