Metal negative electrode and preparation method thereof, electrochemical battery and terminal

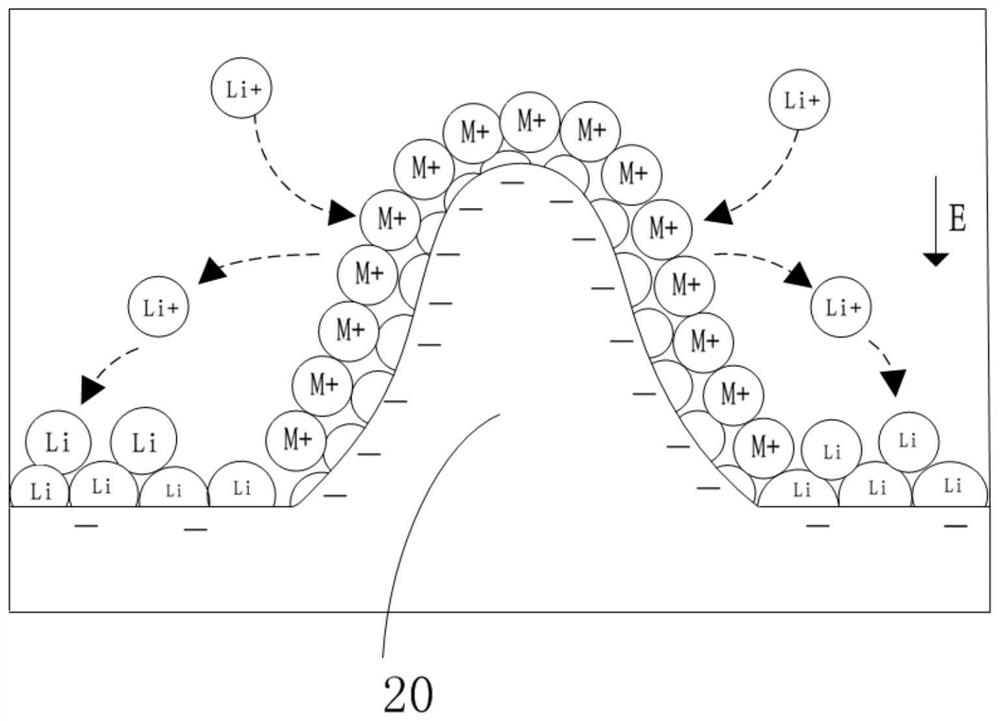

A metal anode and alkali metal salt technology, applied in the field of electrochemical cells, can solve the problems of large volume expansion, uneven metal deposition on the surface of the metal anode, dendrite growth, etc., to stabilize the anode interface, improve the coulombic efficiency of the anode, and reduce the concentration of The effect of differential polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

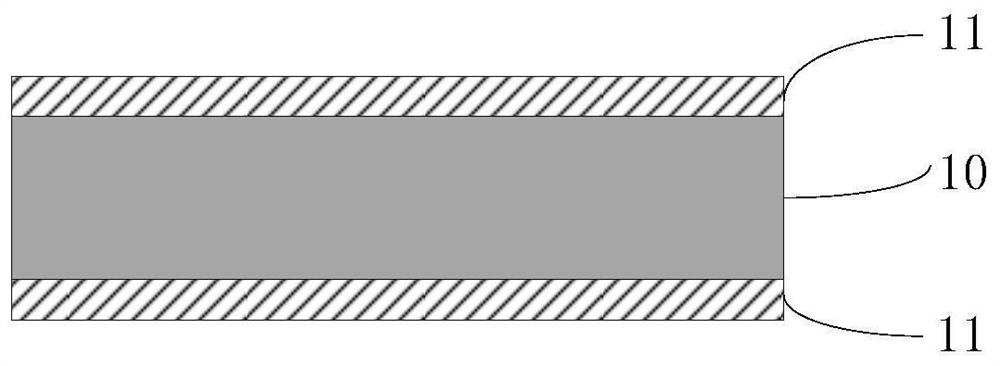

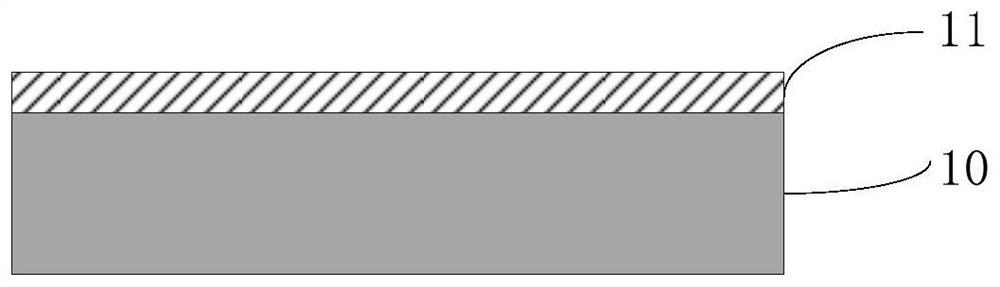

[0065] Correspondingly, the embodiment of the present invention also provides a method for preparing a metal negative electrode, including:

[0066] Add the single-ion conductor polymer alkali metal salt into the organic solvent, and then coat the obtained dispersion on one or both sides of the metal negative electrode body to form a protective layer, wherein the single-ion conductor polymer alkali metal salt includes polymer Skeleton and sulfonimide rubidium salt or cesium sulfonimide grafted on the polymer backbone by chemical bonds.

[0067] In the embodiment of the present invention, the alkali metal salt of the single-ion conductor polymer is the alkali metal salt of the single-ion conductor polymer described in any one of the foregoing embodiments herein, and will not be repeated here.

[0068] In the embodiment of the present invention, the organic solvent can be nitrogen methyl pyrrolidone, acetone, acetonitrile, ethanol, dimethyl carbonate, ethyl methyl carbonate, die...

Embodiment 1

[0080] This embodiment provides a lithium metal negative electrode protected by poly(propylenesulfonyl)(trifluoromethylsulfonyl)imide cesium (A), and its preparation method comprises:

[0081] In a drying room, add 10g of poly(propylenesulfonyl)(trifluoromethylsulfonyl)imide cesium (A) and 0.2g of polyvinylidene fluoride (PVDF) into 100g of dimethyl ether, stir and mix to form a slurry . Then, the above slurry was coated on the surface of unprotected metal lithium by brushing, and the brushing time was 10 minutes to obtain a cesium poly(propylenesulfonyl)(trifluoromethylsulfonyl)imide protective layer with a thickness of 2 μm.

Embodiment 2

[0083] This embodiment provides a metal lithium negative electrode protected by poly(propylenesulfonyl)(perfluorobutylsulfonyl)imide rubidium (B), and its preparation method comprises:

[0084] In a drying room, add 20g of poly(propylenesulfonyl)(perfluorobutylsulfonyl)imide rubidium and 0.2g of polyvinylidene fluoride (PVDF) into 100g of ethylene glycol dimethyl ether, stir and mix to form a slurry . Then, the above slurry was coated on the surface of unprotected lithium metal by scraping, and the scraping time was 2 minutes to obtain a poly(propylenesulfonyl)(perfluorobutylsulfonyl)imide rubidium protective layer with a thickness of 3 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com