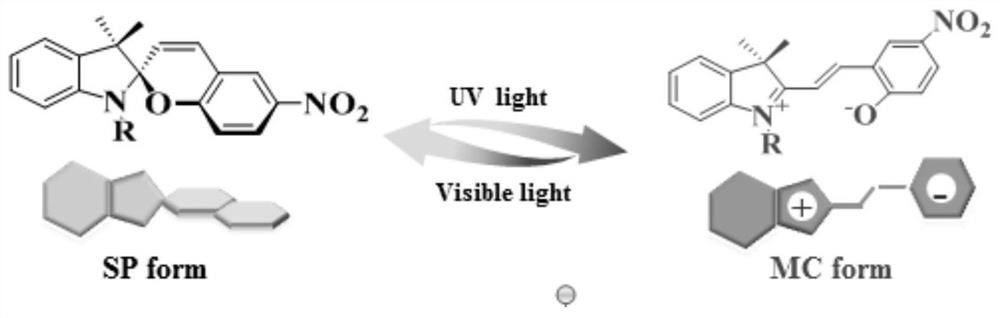

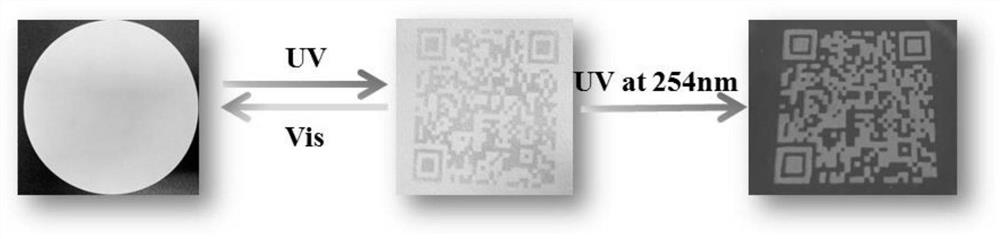

Photochromic fluorescent oily ink and preparation method thereof

A photochromic and fluorescent technology, applied in the field of printing, can solve the problems of eye hazard and poor concealment, and achieve the effect of broadening the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] Accordingly, the present invention provides a method of preparing a fluorescent oily ink based on a lanthanide-based organic frame / screw gallic compound, which includes the following steps:

[0032] (1) Preparation of lanthanide metal organic frame

[0033] 0.1mmol lanthanide compound (specifically LNCL) 3 · 6h 2 O, ln = eu3+ Or TB 3+ ), 0.1mmol ion benzoic acid (H 3 BTC), 10-15 mL n, N-dimethylformamide and 5-10 ml of deionized water were added to the beaker evenly stir. The mixed mixture of the above-mentioned uniform mixing was transferred to the reaction kettle with polytetrafluoroethylene as the liner, and heated from 80-120 ° C in the muffle, which was good, which was good, facilitating the lanthanoid metal organic frame shape. The formation is formed, and it is also convenient to adjust the cooling rate. After the end, the reaction kettle was slowly cooled to room temperature at a temperature of 5-10 ° C / h. After the precipitation was separated by filtration, N, ...

Embodiment 1

[0042] The preparation method of photolored fluorescent oily ink according to the present invention includes the following steps:

[0043] (1) Preparation of lanthanide metal organic frame:

[0044] LNCL 3 · 6h 2 O (0.1mmol ln 3+ = EU 3+ ), Benzophenic acid (H 3 BTC 0.1 mmol), N, N-dimethylformamide (10 mL) and deionized water (5 mL) were added to the beaker evenly stirred for 1 h. The above-mentioned uniform mixed mixture was transferred to the autoclave of the polytetrafluoroethylene liner, and heated at 80 ° C for 12 hours. The reaction vessel was slowly cooled to room temperature at a temperature of 5 ° C / h. The reaction solution produced above was washed with N, N-dimethylformamide and deionized water after filtration, and dried at 50 ° C for 12 hours to obtain a white needle crystal, stored in a dryer.

[0045] (2) Lanthanide metal organic frame adsorbent copiolor compound:

[0046] The above-mentioned lanthanide organic frame (EU-MOFS) 60 mg was activated by immersing in ...

Embodiment 2

[0053] The preparation method of photolored fluorescent oily ink according to the present invention includes the following steps:

[0054] (1) Preparation of lanthanide metal organic frame:

[0055] LNCL 3 · 6h 2 O (0.1mmol ln 3+ = TB 3+ ), Benzophenic acid (H 3 BTC 0.1 mmol), N, N-dimethylformamide (12 mL) and deionized water (8 ml) were added to the beaker evenly stirred for 1 h. The above-mentioned uniformly mixed sample was transferred to a polytereonvonoethylene liner autoclave, and heated at 100 ° C for 20 hours. The reaction vessel was slowly cooled to room temperature at a temperature of 7 ° C / h. The reaction solution produced above was washed with N, N-dimethylformamide and deionized water after filtration, and dried under vacuum for 12 hours at 50 ° C for 12 hours to give a white needle crystal. The collected samples are stored in a desiccator.

[0056] (2) Lanthanide metal organic frame adsorbent copiolor compound:

[0057] The lanthanide organic frame (TB-MOFS) is ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tackiness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com