Epoxy resin corrosion coating and preparation method thereof

A technology of coating and titanium dioxide, which is applied in the field of epoxy resin corrosion coating and its preparation, can solve the problems of inability to meet the anti-corrosion requirements of concrete poles in high-salt-alkali areas, weak corrosion resistance and long-term performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

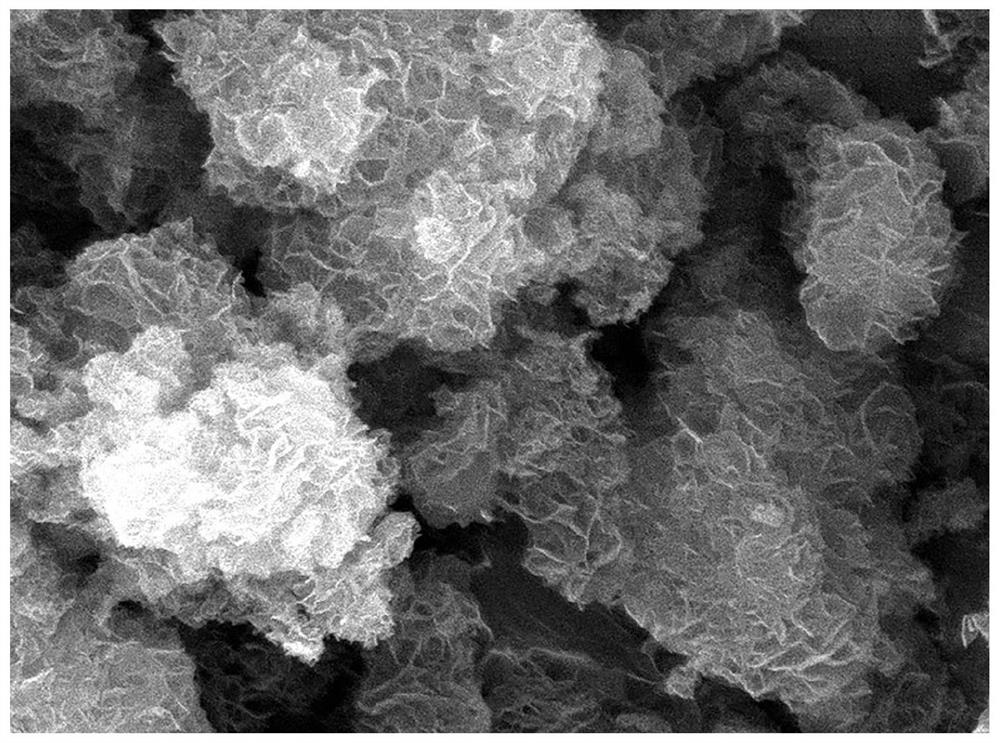

[0054] Preparation Example 1 Preparation of Nanosheet Titanium Dioxide

[0055] Dissolve 0.15g of tetraisopropyl titanate in 0.74g of hydrochloric acid, dissolve in 3g of ethylene glycol solution containing 0.2g of triblock copolymer P123, add the above mixture to 20ml of ethylene glycol, and heat the solvent The reaction was carried out at 170° C. for 20 hours, and the obtained solid precipitate was centrifuged, washed and dried to obtain nanosheet titanium dioxide.

[0056] Preparation Example 2 Preparation of Nanosheet Titanium Dioxide

[0057] Dissolve 0.1g of tetraisopropyl titanate in 0.32g of hydrochloric acid, dissolve in 3g of ethylene glycol solution containing 0.2g of triblock copolymer P123, add the above mixture to 20ml of ethylene glycol, and heat the solvent The reaction was carried out at 200° C. for 20 hours, and the obtained solid precipitate was centrifuged, washed and dried to obtain nanosheet titanium dioxide.

[0058] Preparation Example 3 Preparation o...

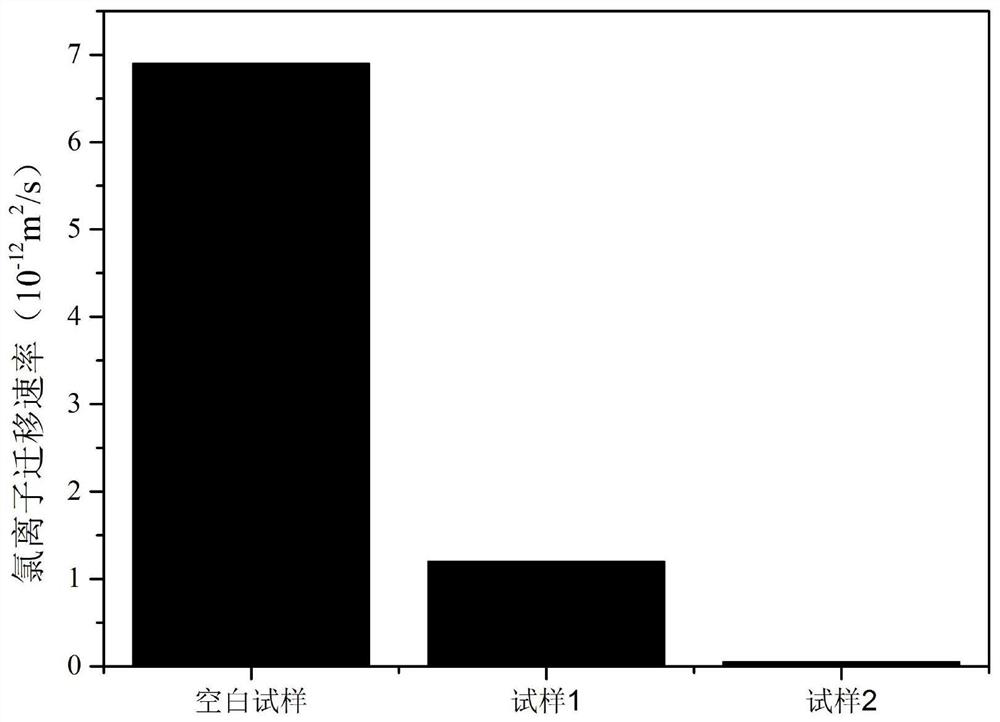

Embodiment 1

[0061] A kind of epoxy resin is used for the anti-corrosion anticorrosion coating of chloride ion on the surface of concrete electric pole, comprises following components;

[0062] The body is epoxy resin emulsion;

[0063] 5 parts curing agent;

[0064] 5 parts of diluent;

[0065] 10 parts of defoamer;

preparation example 1

[0066] 10 parts of nanosheet titanium dioxide prepared in Preparation Example 1.

[0067] The curing agent is polyamide or aromatic amine or aliphatic amine;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com