Adhesive and preparation method thereof, silicon-carbon negative electrode material and lithium battery

A technology of adhesive and silicon carbon, applied in the direction of negative electrode, adhesive, secondary battery, etc., can solve the problem of lack of adhesive of silicon carbon negative electrode material, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] (1) Get 1.03g polystyrene macroinitiator and 3g 2-(2-methoxyethoxy) ethyl ester monomer and dissolve in N,N-dimethylformamide, and use liquid nitrogen to the reaction system Freezing-pumping-thawing was repeated three times to remove oxygen, then filled with nitrogen and added 0.05g CuBr and 0.06g PMDETA, the molar ratio was 2-(2-methoxyethoxy) ethyl ester monomer:polystyrene Molecular initiator: PMDETA: CuBr=50:1:1:1, the concentration of the monomer is 2.5 mol / L, and the reaction is quenched with liquid nitrogen after reacting at 60° C. for 4 hours. The reacted mixed solution was passed through a neutral alumina column to remove the copper catalyst. The solution was subsequently precipitated three times in a mixed solution of diethyl ether / petroleum ether (volume ratio: 1 / 1) of ten times the volume. Finally, the precipitated product was dried at 40 °C to constant weight to obtain PS-b-P(EO) 2 diblock copolymers.

[0053] (2) Take 0.913g of PS-b-P(EO) prepared in (1...

Embodiment 2

[0057] The preparation method, reaction conditions and purification method of PSEA three-block copolymer copolymer are the same as embodiment 1, but the charging ratio is different, and the stoichiometric ratio of three kinds of blocks is styrene: 2-(2-methoxyethylene Oxy) ethyl ester: acrylic acid = 30:50:600, as binder A2.

[0058] The binder A2 was used to prepare silicon carbon negative electrodes for lithium-ion batteries according to the above method and assembled into lithium-ion batteries to test their performance.

Embodiment 3

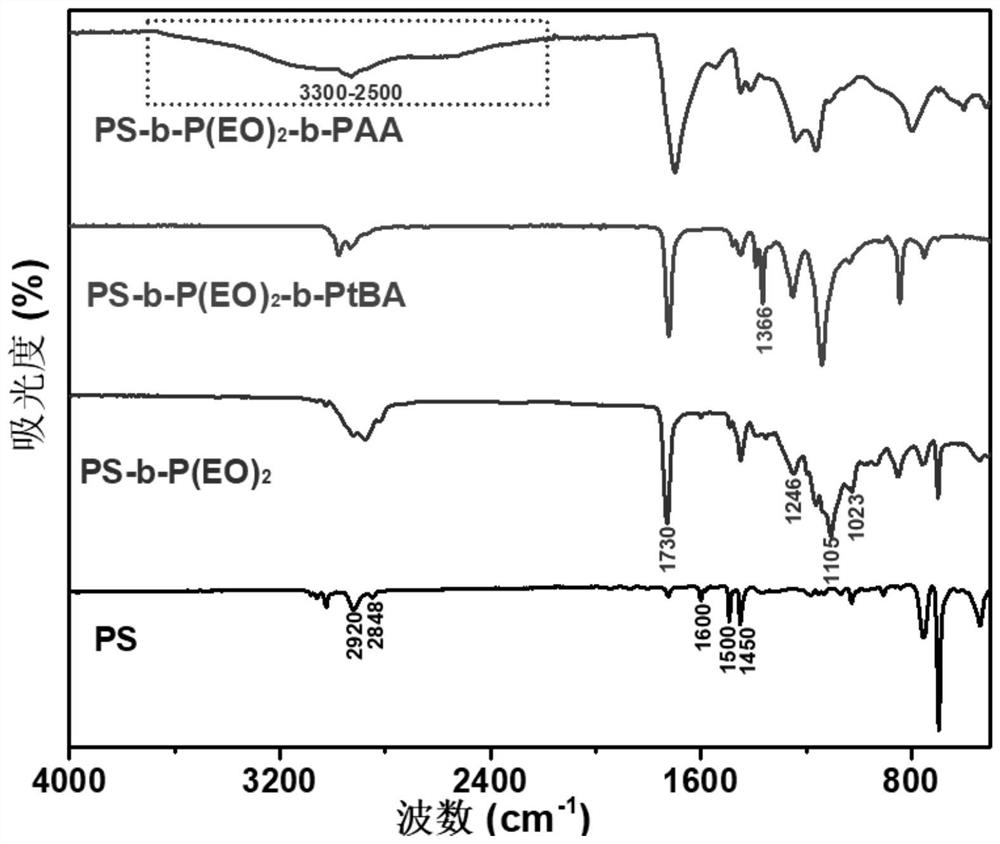

[0060] The preparation method, reaction conditions and purification method of PSEA three-block copolymer copolymer are the same as embodiment 1, but the charging ratio is different, and the stoichiometric ratio of three kinds of blocks is styrene: 2-(2-methoxyethylene Oxy)ethyl ester:acrylic acid=30:60:500, as adhesive A3; see figure 1 It is the infrared spectrogram of the PSEA triblock copolymer copolymer prepared in this embodiment, as can be seen from the figure in the spectrum of PS, 2923cm -1 , 2849cm -1 The absorption peak at corresponds to -CH 2 -Antisymmetric stretching, symmetrical stretching vibration, 1600cm -1 , 1580cm -1 , 1500cm -1 , 1450cm -1 The absorption band at corresponds to the ring vibration of the benzene ring;

[0061] Diblock Polymer PS-b-P(EO) 2 The spectrum is at 1730cm -1 The new absorption peak that appeared nearby corresponds to the stretching vibration of -C=O, at 1246cm -1 , 1105cm -1 The antisymmetric stretching vibration correspondin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com