Surface treating agent and method for p-type bismuth telluride-based material applied to thermoelectric device

A technology of surface treatment agent and bismuth telluride base crystal, which is applied in the manufacture/treatment of thermoelectric devices, thermoelectric device node lead-out materials, chemical instruments and methods, etc., can solve the problem of increasing production links and production costs, p-type tellurium Bismuth-based wafer damage, reduced yield and production efficiency and other issues, to achieve the effect of improving yield and production efficiency, improving interface bonding strength, reducing interface contact resistance and interface thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A surface treatment method for a p-type bismuth telluride-based material, comprising the following steps:

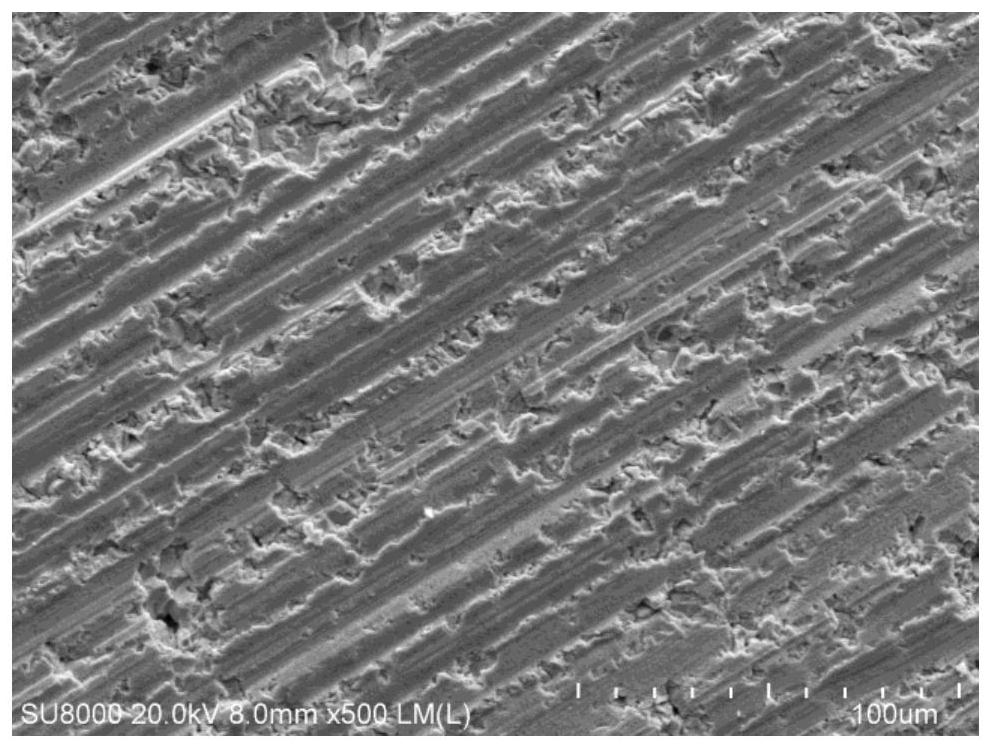

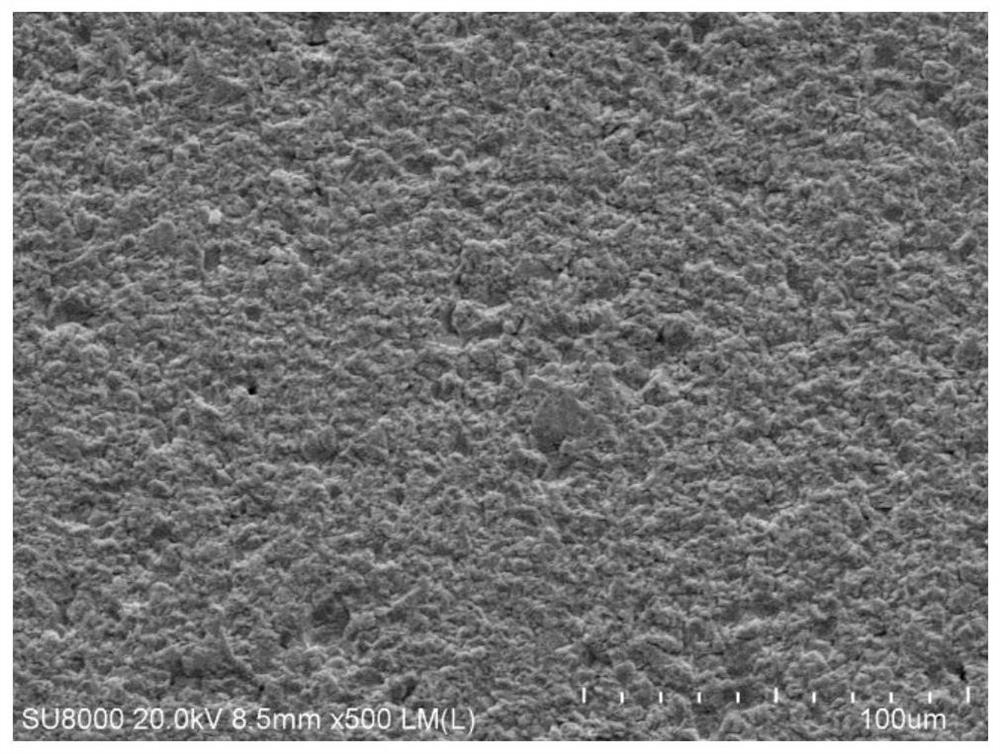

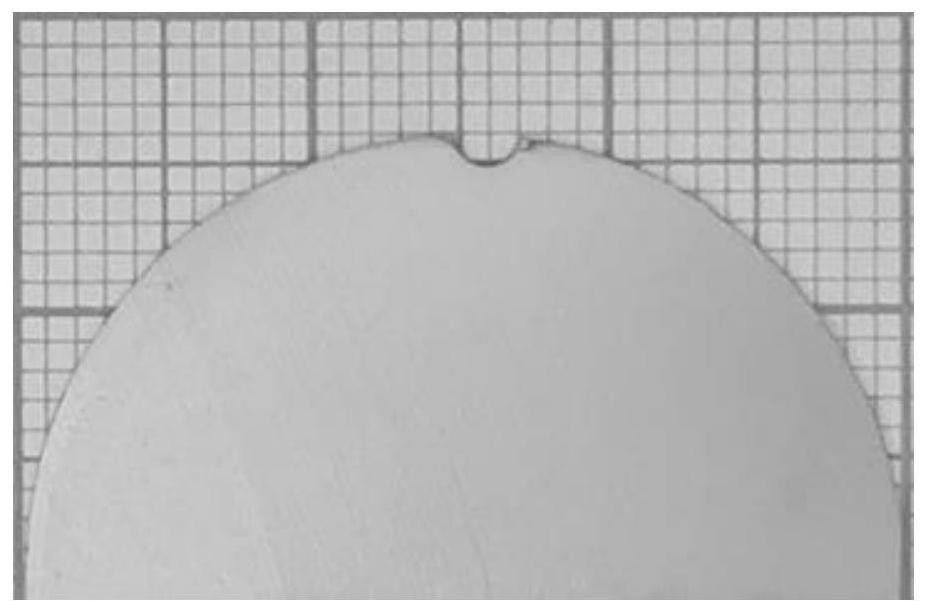

[0036] 1) A semicircular p-type bismuth telluride-based wafer with a diameter of 30 mm and a thickness of 0.3 mm is washed with acetone and degreased to remove surface pollutants, dehydrated with absolute ethanol, and dried with an OLS5000 laser scanning microscope for surface roughness testing. The surface is rough The degree Sa is 0.197 μm, then immersed in the roughening solution (the composition of the roughening solution is 10% (volume) of hydrochloric acid, 40% (volume) of hydrogen peroxide, 5% (volume) of nitric acid, and the balance is water), and the roughening temperature is 30 ℃, coarsening time 5min;

[0037] 2) The roughened p-type bismuth telluride-based wafer in step 1) is transferred to ash removal solution (the composition of the ash removal solution is 50% (volume) of hydrofluoric acid, 10% (volume) of hydrochloric acid, and 5% (volume) of nitric...

Embodiment 2

[0059] A surface treatment method for a p-type bismuth telluride-based material, comprising the following steps:

[0060] 1) A semicircular p-type bismuth telluride-based wafer with a diameter of 30 mm and a thickness of 0.3 mm was washed with acetone and degreased to remove surface pollutants, dehydrated with absolute ethanol, dried, and then observed by SEM, and then immersed in a roughening solution (roughened The composition of the chemical solution is 20% (volume) of hydrochloric acid, 30% (volume) of hydrogen peroxide, 5% (volume) of nitric acid, and the balance is water), the roughening temperature is 30 ° C, and the roughening time is 10 minutes;

[0061] 2) The roughened p-type bismuth telluride-based wafer in step 1) is transferred to ash removal solution (the composition of the ash removal solution is 40% (volume) of hydrofluoric acid, 10% (volume) of hydrochloric acid, and 5% (volume) of nitric acid ( volume), the balance is water), and the ash removal temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com