Preparation method and application of layered high-entropy oxide sodium ion battery positive electrode material

A sodium-ion battery and cathode material technology, applied in battery electrodes, active material electrodes, positive electrodes, etc., can solve the problems of high charge transfer resistance, low ionic and electronic conductivity, low rate performance, etc., and achieves low equipment requirements. The effect of good crystallinity and good sodium storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

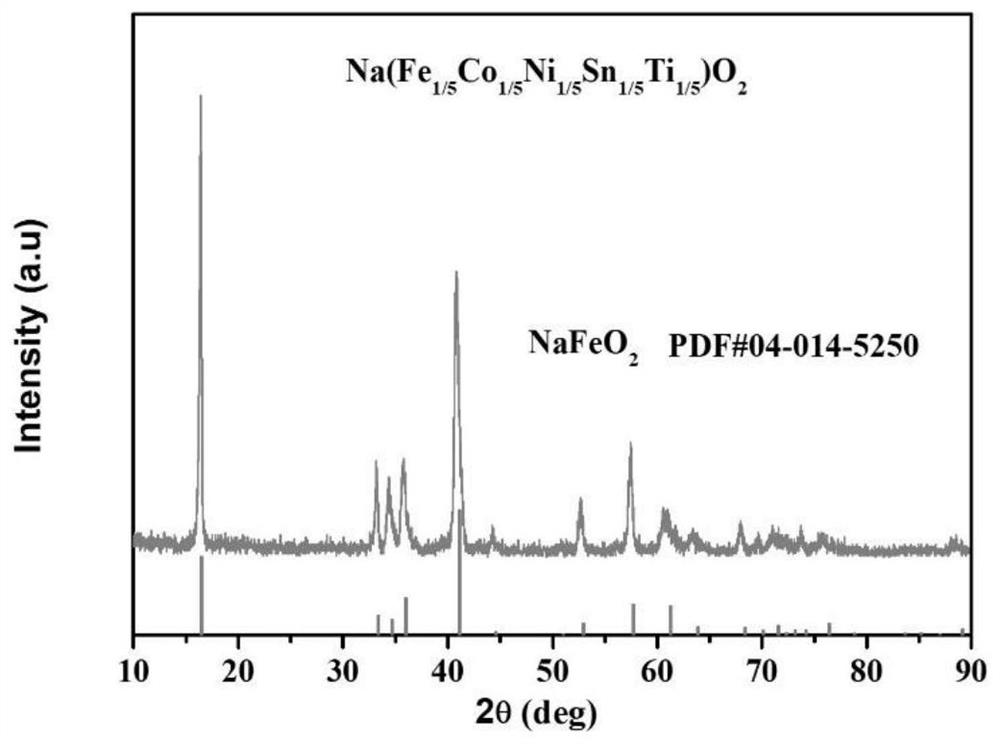

Embodiment 1

[0039] A preparation method of a layered high-entropy oxide sodium ion battery positive electrode material, comprising the following steps:

[0040] Step 1: Take Fe with a purity of 99% 2 o 3 (0.1mol, 0.484g), Co 3 o 4 (0.067mol, 0.489g), NiO (0.2mol, 0.453g), TiO 2 (0.2mol, 0.484g) and SnO with a purity of 99.5% 2 (0.2mol, 0.909g) powder was mixed uniformly to obtain material A;

[0041] Step 2: Mix material A with Na 2 CO 3 According to the molar ratio of 1:1.02, put the ingredients into the polyurethane ball milling tank, and add an appropriate amount of zirconia balls (the mass ratio of balls and materials is 10:1) and absolute ethanol dispersant; then place the polyurethane ball milling tank on the planetary On the station of a type ball mill, ball mill continuously at a speed of 300r / min for 3 hours to obtain a fully mixed slurry; then put it in an oven, dry it at a constant temperature at 50°C, and grind it to powder to make a precursor C;

[0042] Step 3: Put ...

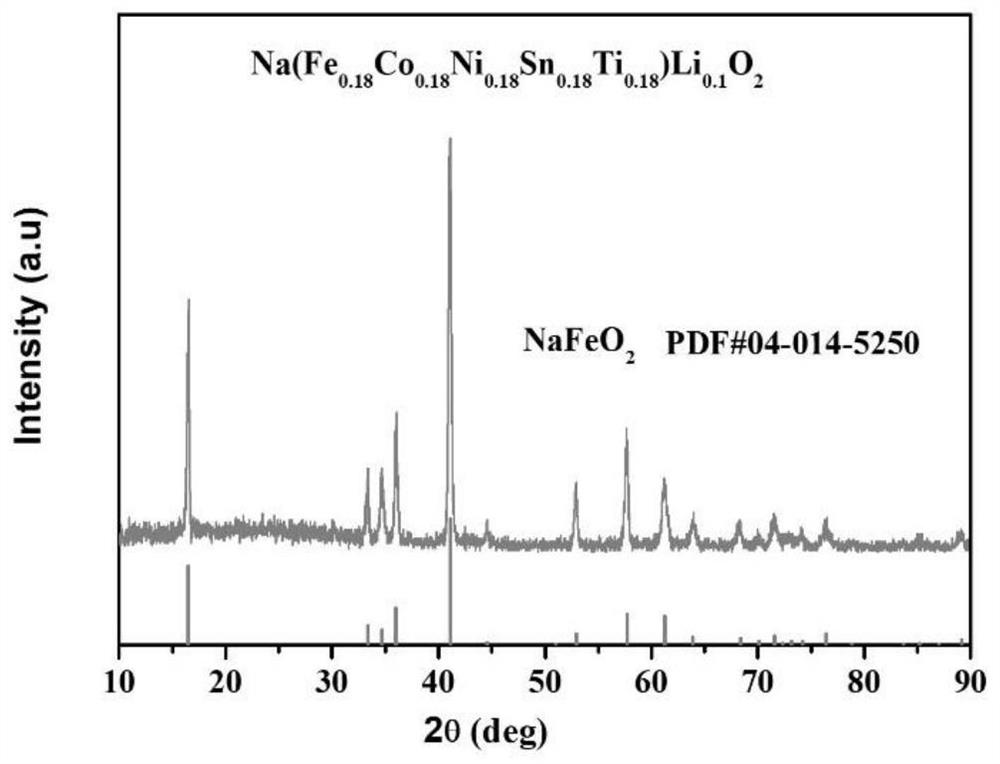

Embodiment 2

[0047] A preparation method of a layered high-entropy oxide sodium ion battery positive electrode material, comprising the following steps:

[0048] Step 1: Take Fe with a purity of 99% 2 o 3 (0.09mol, 0.436g), Co 3 o 4 (0.060mol, 0.438g), NiO (0.18mol, 0.407g), TiO 2 (0.18mol, 0.436g) and SnO with a purity of 99.5% 2 (0.18mol, 0.818g) powder was mixed uniformly to obtain material A;

[0049] Step 2: Mix material A with Li with a purity of 99.66% 2 CO 3 (0.05mol, 0.114g, excess 2%mol) mixed uniformly to make material B;

[0050] Step 3: Combine material B with Na 2 CO 3 According to the molar ratio of 1:1.02, put the ingredients into the polyurethane ball mill tank, and add an appropriate amount of zirconia balls (the mass ratio of the ball to the material is 10:1) and anhydrous ethanol dispersant; then place the polyurethane ball mill tank on the planetary ball mill On the station, continuously ball mill at a speed of 300r / min for 3 hours to obtain a fully mixed slu...

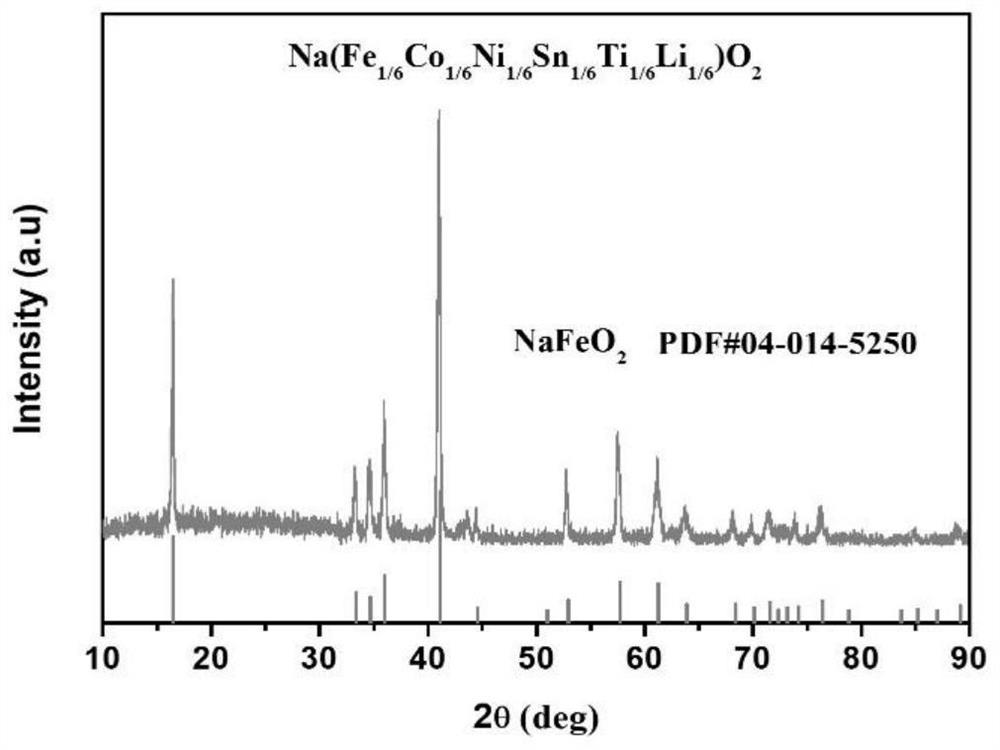

Embodiment 3

[0056] A preparation method of a layered high-entropy oxide sodium ion battery positive electrode material, comprising the following steps:

[0057] Step 1: Take Fe with a purity of 99% 2 o 3 (0.083mol, 0.402g), Co 3 o 4 (0.056mol, 0.409g), NiO (0.167mol, 0.378g), TiO 2 (0.167mol, 0.404g) and SnO with a purity of 99.5% 2 (0.167mol, 0.759g) obtained material A after powder mixing;

[0058] Step 2: Mix material A with Li with a purity of 99.66% 2 CO 3 (0.083mol, 0.189g, excess 2%mol) mixed to make material B;

[0059] Step 3: Combine material B with Na 2 CO 3 According to the molar ratio of 1:1.02, put the ingredients into the polyurethane ball mill tank, and add an appropriate amount of zirconia balls (the mass ratio of the ball to the material is 10:1) and anhydrous ethanol dispersant; then place the polyurethane ball mill tank on the planetary ball mill On the station, continuously ball mill at a speed of 300r / min for 3 hours to obtain a fully mixed slurry; then put...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com