Honeycomb metal ceramic bifunctional catalyst, application thereof and method for preparing hydroxycitronellal

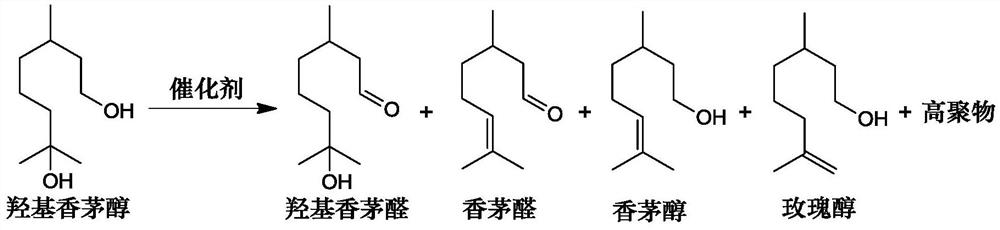

A dual-functional catalyst and honeycomb metal technology, which is applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, carbon-based compound preparation, etc., can solve the problem of large impact on product aroma quality, harsh operating conditions, Difficulties in industrial production and other problems, to achieve the effect of improving charge distribution and alkaline environment, increasing conversion rate, and improving catalytic oxidation performance of platinum group metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

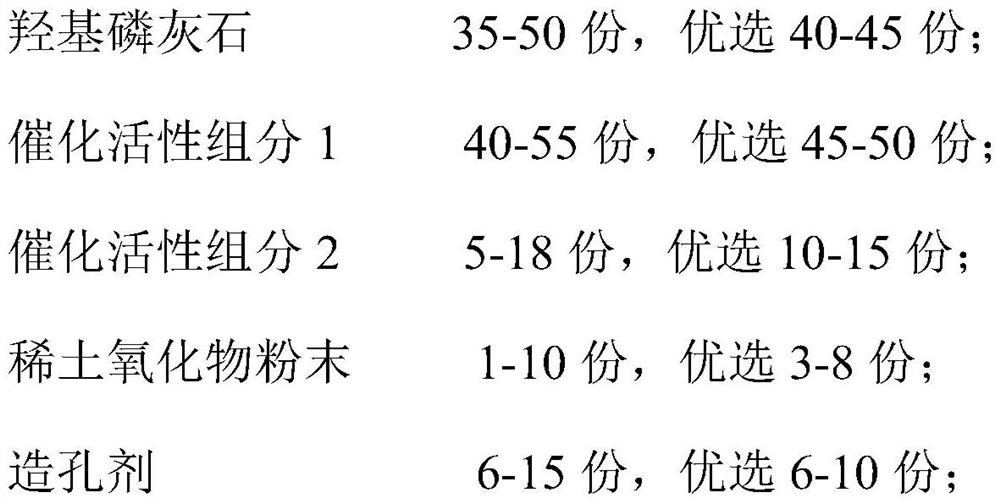

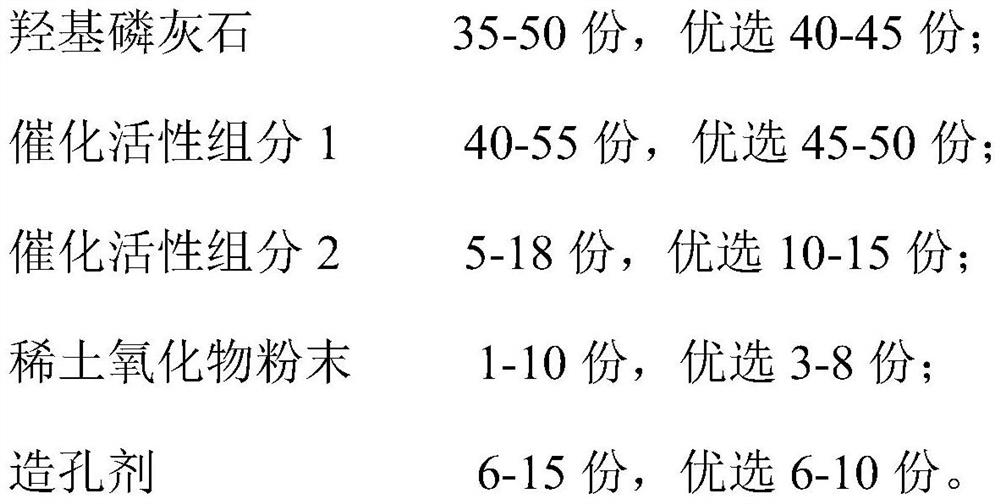

[0048]Preparation of honeycomb cermet bifunctional catalyst: mix hydroxyapatite, copper oxide powder, palladium powder, lanthanum oxide powder, polyethylene glycol (PEG4000) according to the ratio of 40:50:10:5:6, and ball mill evenly Spray granulation, extrusion molding, drying, and then vacuum liquid-phase sintering at 800°C, keep warm for 60 minutes and then cool to room temperature with the furnace to obtain a honeycomb cermet bifunctional catalyst with a specific surface area of 31.2m 2 / g, the pore volume is 0.23mL / g.

[0049] Preparation of hydroxycitronellal by dehydrogenation-oxidation reaction: Fill 100g of honeycomb cermet catalyst particles into a fixed bed, heat the fixed bed with heat transfer oil to a reaction temperature of 150°C, and adjust the pressure of the reaction system to 1.00 bar. Use a metering pump to inject hydroxycitronellol into the vaporization chamber at a flow rate of 8.3g / min for vaporization, nitrogen enters the vaporization chamber at a ra...

Embodiment 2-6

[0051] Carry out the preparation of catalyst and the preparation of hydroxycitronellal according to the step of embodiment 1, corresponding preparation parameter and reaction result are as shown in table 1 and 2, no dehydration by-product is generated in embodiment 2-6, high polymer<0.01 %.

[0052] Table 1 catalyst preparation conditions

[0053]

[0054] Note: in embodiment 2-6, polyethylene glycol is PEG4000, and polyvinyl alcohol is PVA4000

[0055] Table 2 dehydrogenation reaction conditions and results

[0056]

[0057] The life of the catalyst in Example 6 was inspected. The catalyst was continuously catalytically operated for 3500 hours in a fixed bed, and the conversion rate and selectivity of the catalytic reaction remained above 99.5%, without carbon deposition and deactivation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com