Purification method for hydrogen sulfide and hydrogen phosphide in acetylene production by calcium carbide method

A technology of hydrogen sulfide and calcium carbide method, which is applied in the field of purification, can solve the problems of no waste liquid treatment and discharge, and achieve the effects of reducing maintenance costs, simple and easy treatment, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

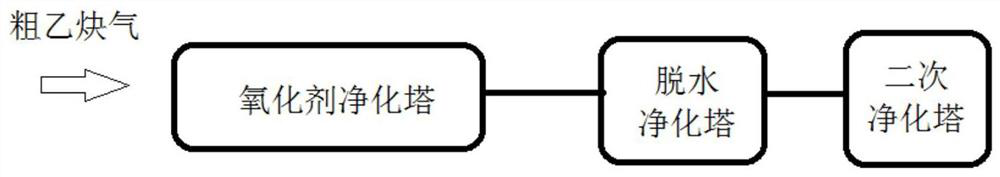

Method used

Image

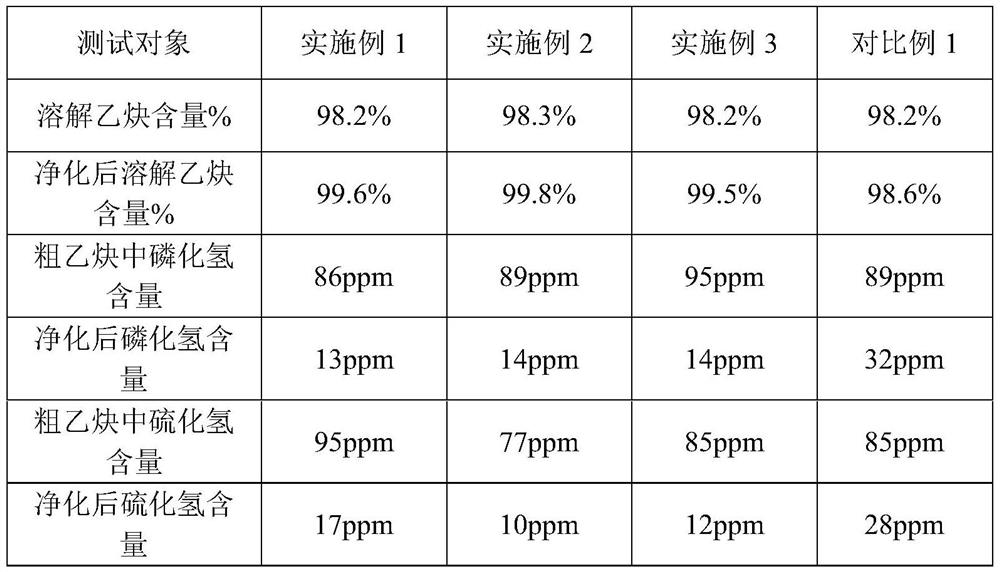

Examples

Embodiment 1

[0025] A method for purifying hydrogen sulfide and phosphine in the production of acetylene by a calcium carbide method, comprising the following steps:

[0026] (1) Crude acetylene gas is first processed through the oxidant purification tower, which is equipped with filler one, and the preparation method of filler one is as follows: the packing density of the filler is 0.65g / cm 3 Get mass concentration and be 35% ferric chloride solution 100mL, be that the sodium hydroxide solution of 1% is regulated pH value to be 4~6 with mass concentration, pour into the diatomaceous earth adsorption that granular particle diameter is 1-3mm In the agent container, the amount of diatomite is 100g; the solution is completely immersed in diatomite; after the mixture is placed at room temperature for 7 days, the excess liquid is filtered off, dried naturally for 3 days, and loaded into the oxidant purification tower in layers. Seal with a filter screen; the working temperature of the oxidant p...

Embodiment 2

[0030] A method for purifying hydrogen sulfide and phosphine in the production of acetylene by a calcium carbide method, comprising the following steps:

[0031] (1) Crude acetylene gas is first processed through the oxidant purification tower, which is equipped with filler one, and the preparation method of filler one is as follows: the packing density of the filler is 0.65g / cm 3 Get mass concentration and be 41% ferric chloride solution 100mL, be that the sodium hydroxide solution of 5% mass concentration is to adjust pH value to be 4~6 with mass concentration, pour into the diatomaceous earth adsorption that granular particle diameter is 1-3mm In the agent container, the amount of diatomite is 100g; the solution is completely immersed in diatomite; after the mixture is placed at room temperature for 7 days, the excess liquid is filtered off, dried naturally for 5 days, and loaded into the oxidant purification tower layer by layer. Seal with a filter screen; the working temp...

Embodiment 3

[0035] A method for purifying hydrogen sulfide and phosphine in the production of acetylene by a calcium carbide method, comprising the following steps:

[0036] (1) Crude acetylene gas is first processed through the oxidant purification tower, which is equipped with filler one, and the preparation method of filler one is as follows: the packing density of the filler is 0.65g / cm 3 Get mass concentration and be 38% ferric trichloride solution 100mL, be that the sodium hydroxide solution of 3% mass concentration is to adjust pH value to be 4~6 with mass concentration, pour into the diatomaceous earth adsorption that granular particle diameter is 1-3mm In the agent container, the amount of diatomite is 100g; the solution is completely immersed in diatomite; after the mixture is placed at room temperature for 7 days, the excess liquid is filtered off, dried naturally for 4 days, and loaded into the oxidant purification tower layer by layer. Seal with a filter screen; the working t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com